The land of boots, mud guards and bonnets, a place where if it don't fit under the hood er, bonnet just cut a hole and let it whine and belch fire right out in the open for all the world to see and be amazed,

I like it!

I like it!

Kiwi trash takin'

Right there!

The gila monster build is all about how madmike1157 has made stuff work.

Despite what he says, often the first time.

This guy has brought out the details by the noble Gran Torino "Walt teaches Thao" trash talk ,

just because mike is social while he asks the hard questions and has other stuff to say rather than just a fact finding mission.

I've hunted him down here because I'm just knocked out by how he works.

Although I dabble in Electronics and electric control systems all the time,

they have screwed me over,

gain control,

wiring,

sensor polling,

pull up resistors.

Proxy sensors

Anaolgue /Digital conversions.

Power Spectural Density

This is who I am.

"https://www.linkedin.com/pulse/street-bump-birth-android-road-roughness-applications-dean-stevenson/"

I'm lucky because I've had the best helpers in the world.

To see this stuff Mad Mike 1157 is unfolding is a thing of true beauty, people.

I'm a dirt under the nails techncian too, but I love carbs, turbos and the idea that you give a person too much electronic piano wire....and they'll hang 'em selves with it.

I'll do MS, but it'll be to run my Quad YFA Carter carbs.

I've done the electronics stuff, and like MS, but like Pulse Width Modulation, metering rod feedback carbs and cast iron headed i6's a whole lot more.

Then it may hinder the things ability to keep the engine cool in traffic,...I think the on/off thing may be the best solution...I just gotta figure out what happened to my output.What about restricting the inlet of the water pump? Maybe a washer allowing half the volume?

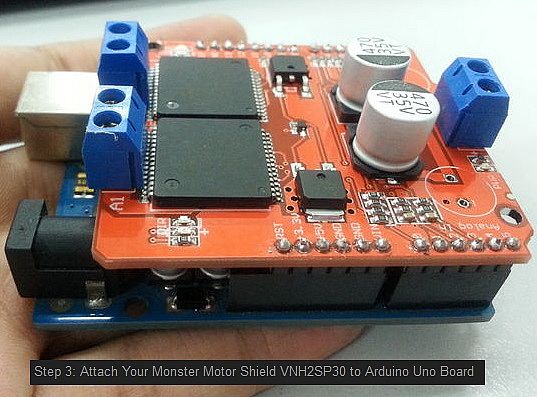

Hmm. As far as the software is concerned there is nothing I can think of in tunerstudio that would support that. We could use an output not meant for this but manipulate the tables to make it happen. .ini files can be altered at will, it could be done I think.Let me introduce you to my friend PWM...

Use a PWM controller to vary the speed of the water pump to keep the coolant temp where you want it. There may be such an animal built into the MS to do just that. @a91what where are you?

Or use a PWM controller to do the same thing for the radiator fans....

The DC Control would indeed be simple but somewhat expensive.Hmm. As far as the software is concerned there is nothing I can think of in tunerstudio that would support that. We could use an output not meant for this but manipulate the tables to make it happen. .ini files can be altered at will, it could be done I think.

Then we would need a circuit heavy enough to carry a load that large.

I believe a dcc controller would be a better fit and simpler.

I like the way you think outside the box J.

Huh, what'd you say?Now your fitting in.

However you seem very versed in ecu hardware I would love your technical jargon over in the megasquirt help thread. We will just need to water it down a bit so it's easy for the regulars to understand.

I think I found it.I think several cars nowadays have closable grill fins. In your spare time, build a remote radiator block off....after you find your missing MS I/O ports. That's probably easier than taking the engine apart.

Well...hit a milestone today...

No car progress.....MOF the car did its level best to poke me in the eye all day.

The milestone is that I was able to spend the whole damn day down there trying to fix it.

And I'm not in mortal pain because of it.

I don't know whether it was the doctor, or the therapist,.....one of them told me that this day would come.

One where I didn't feel like I was so sore all I could do was to lay down and die.

I sat in either the driver seat, the floor next to the driver door ( cannot kneel), and the passenger seat trying to get THE GODDAMNED ECU TO WORK.

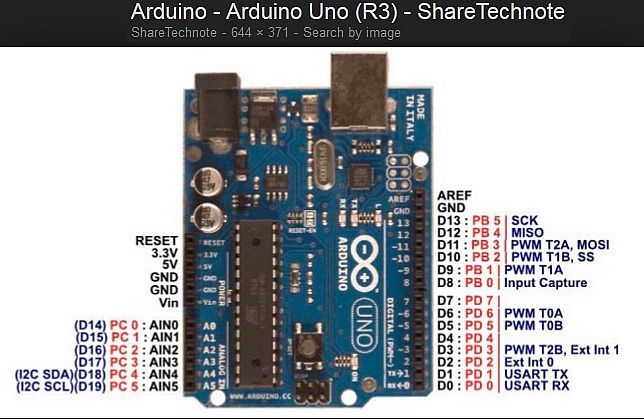

It should be so simple really.....A MSII lets you wire outputs in anticipation of using them to do things......

Things like........ohhhhhh running a cooling fan,....running a water pump,...triggering your idle valve when you turn on your AC...

My ECU is doin good just to run my engine.

Try as I may, that " simple circuit" phcked me....over, and over again.

I feel so used..

There is something wrong with the circuit I'm fighting with. Despite the fact that the people at DIY tell me that there's nothing wrong with my system,.....they're all wrong...I've spent too many hours chasing my tail to only end up at the exact same conclusion..

If I had a AR15, and a bump stock,....id put 800 rounds into that piece of sht.