Fortunately for the sites administrator,.. I'll be the Sites' Huckleberry.

View: https://youtu.be/c8SFVh5ONQA

Fortunately for the sites administrator,.. I'll be the Sites' Huckleberry.

where do I get that?What about phenolic material, easy to shape and work with.

Hdpe plastic is gasoline safe and good to 250* temps I doubt your intake surface will get above engine temp.

I was searching eBay for both lots of options there Amazon probably has it as well. I think most cutting boards are made from hdpe as well.where do I get that?

It''s a perfect world.

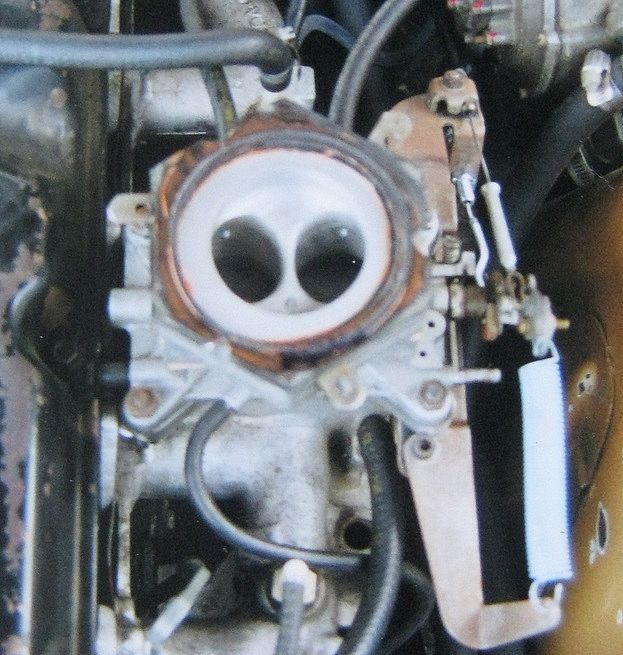

These are the gutted version of what came to me this afternoon. Main throttle shaft, linkage, throttle blade shafts, all removed. I'm gonna be able to do exactly what I wanted to do. The injector bosses will work, the main throttle shaft isn't hardened, so It can be cut and drilled. The upper hole was for an air injection system probably for EGR, but will become my vacuum ports.

What wont work as well is that there are only 3 bushings between the 6 throttle bodies. One on each end, and one in the middle. When I cut through that shaft to extend it between the throttle bodies, there wont be support between several of the inner units. Obviously wasn't a problem with the factory system,.. and it might not be an issue if I can get the sleeves that will go over the cut shaft to fit tightly enough,...but that'll be one more item that I have to get perfect, or the shaft will wobble.

A wobbly shaft might bind somewhere... and it would be bad to have a wobbly shaft. (I'm leaving myself wide open here)...

The other issue is that I can direct mount the throttle bodies,but how thick does the plate have to be to adequately transition from the 1.3" x 2" oval bottom of the throttle body to the round 1.625" opening at the port entrance....and given that there will be some of the round port on the head "cut off" on the top and bottom, am I better off going back to putting a tube between the head, and the throttle body to aid in that transition?. I really want to keep it simple and clean and just use a single plate.... I wonder if I can make this out of something other than metal?

I got the rod back this afternoon,....Put the piston on it, and stuffed it in the hole...Now the short block is assembled.

I got to figure out the TB dilemma and move forward..I don't really want to give up the integral injector mount boss that are built into the throttle bodies....................Decisions, decisions.

...Nothing to worry about! ( yuk yuk)

...Nothing to worry about! ( yuk yuk)  Pour the coal to it,...what are you.....a wuss?"!!!

Pour the coal to it,...what are you.....a wuss?"!!!@CarMichael Angelo

Bolting the throttle bodies directly to the head without a tuned length intake runner is going to play havoc with any ram air effect that would be a power booster. When the sonic wave rebounds from hitting the closed intake valve, the next thing it hits is the throttle butterfly which either chokes the wave or makes it operate up in the high RPM range that the engine will not operate in.

Using a long stack on the other side of the throttle butterfly to tune the overall runner length is going to have the same problem. The throttle butterfly is going to have a negative effect on the sonic pressure wave because some of the sonic energy is going to bounce off of it and reflect back to the common plenum for the air cleaner.

See https://www.google.com/search?sourc...j0i10k1j0i22i30k1j33i22i29i30k1.0.R8_Nn5li2jQ

See http://www.wallaceracing.com/runnertorquecalc.php for a calculator to help determine intake runner size and length

http://www.wallaceracing.com/runnertorquecalc.php

Connecting rods fail due to expansive loads as a result of excessive RPM. Dumping 15 psi on the rod is considered compressive. Harder to control stretch as opposed to being compressed.I like the upgrade plan.

But with no Turbo-is it really that big an issue?

I appreciate that Joe.....

How did it work so well in this configuration then?

Same throttle bodies, bolted directly to the head.

If it's a half an inch...But I'm not thinking that's what Joe is talking about.Would the distance of the runner in the head factor in?

What is the difference between the run in your head and the head the vb came off of?

Would the distance of the runner in the head factor in?

What is the difference between the run in your head and the head the vb came off of?

There are these little bug eye screens that sit on little short velocity stacks that is in my wish list on Amazon..Won't a common air plenum take away from the aesthetic? In my mind I imagined 6 velocity stacks on the side of the engine, looked bitchin. (I guess those would be hard to filter)

I see alot of stacks come with some kind of replaceable mesh filter. They also sell foam prefilters that attatch over the mesh filter for daily use.