Check the firing order when you reassemble the engine enough to test the compression. Since you don't know what the firing order is, you have no way of being sure that the spark plug wires are in the correct order. If you are going to build an EFI engine, remember that the computer needs to match the engine firing order.

This doesn’t prove that the block is a HO block. Some trucks evidently use a HO firing order with a low lift cam (this will result in less than the desired HP output). However, it will definitely prove that a block can’t be HO because the firing order is wrong.

Remove the #1 & #3 spark plugs. Put your finger in #1 spark plug hole. Crank the engine over until you feel compression on #1 cylinder. Slowly turn the engine until the TDC mark and the timing pointer line up. Mark TDC on the balancer with chalk or paint. Put your finger in #3 spark plug hole and crank the engine 90 degrees. You should feel pressure trying to blow past your finger. If you do not feel pressure, repeat the process again. If you feel pressure, it is a HO engine.

No pressure the second time, remove spark plug #5. Put your finger in #1 spark plug hole. Crank the engine over until you feel compression on #1 cylinder. Put your finger in #5 spark plug hole and crank the engine 90 degrees. If you feel pressure now, the engine is not a HO model, no matter what it says on the engine.

Using a small carpenter or machinist square to mark the harmonic balancer off into 90 degree sections may be helpful here.

A 15/16 deep socket & breaker bar or ratchet may be used to turn the engine.

The HO firing order is 1-3-7-2-6-5-4-8.

Non HO firing order is 1-5-4-2-6-3-7-8

Do an end to the injector wring test to make sure that the injectors are properly sequenced for a HO engine and computer

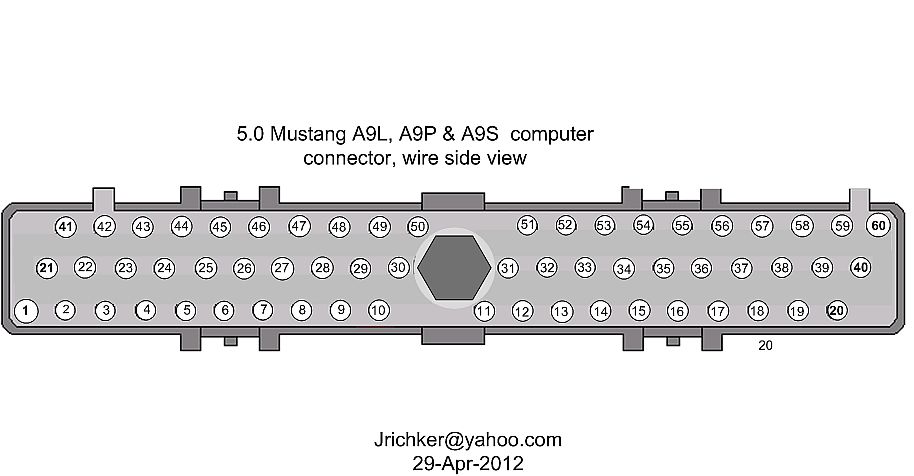

Disconnect the main connector from the computer and pull it down so that you have good access to the computer side of the connector.

Place one voltmeter lead in pin 40 or 60 - they are both the main computer power ground. This lead does not change for any of the tests

Disconnect

all the injector connectors from the injectors.

You will re-connect them one at a time to do the testing. Once you have checked an injector lead, disconnect it before testing the next injector. Fail to do this and you will get incorrect results

Turn the ignition switch to Run

Check pins 37 & 57; you should see 12 volts.

Computer wiring harness connector, wire side

Computer wiring harness connector, computer side

Here are the HO injector wires that are different; check to see that you have 12 volts on them one at a time.

Connect injector #3, look for 12 volts on pin 12 on the computer. Disconnect the injector connector from the injector before testing the next wire.

Connect injector #7, look for 12 volts on pin 42 on the computer. Disconnect the injector connector from the injector before testing the next wire.

Connect injector #5, look for 12 volts on pin 14 on the computer. Disconnect the injector connector from the injector before testing the next wire.

Connect injector #4. look for 12 volts on pin 13 on the computer. You are finished now and can reconnect all the injector connectors to the injectors.