No problem..thank you... I appreciate and weigh everyone's input on this project. We all have an interest in these cars, tastes and preferences will vary, but input is good. If I have a pic or can take one I will post it. I am trying to figure out taking nice pictures...I am not too good at it lol.

I have built cars before, but this is pretty out there.. as in no one else really does this to these cars.. except perhaps the original iteration (sudden death).

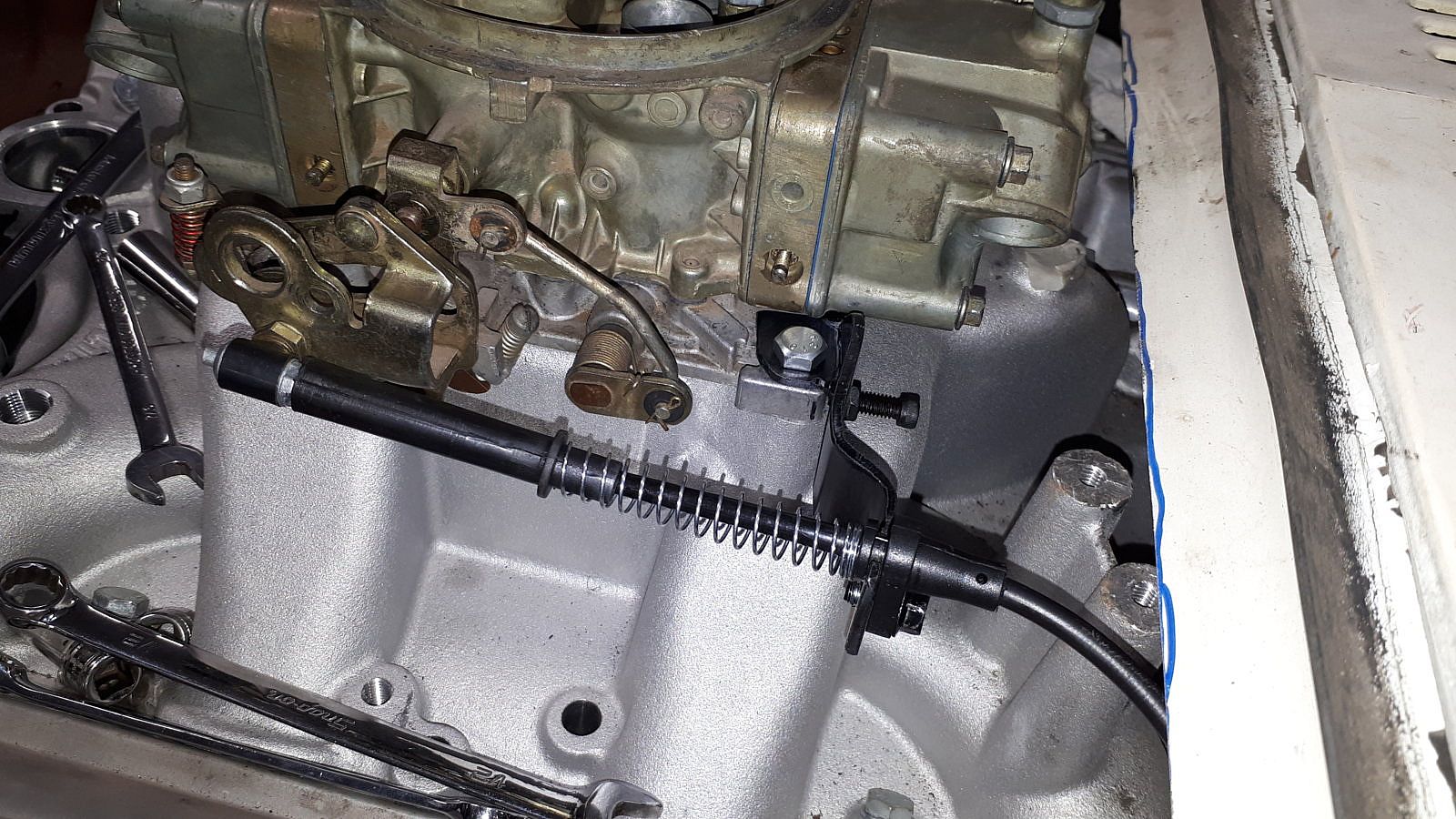

...Yesterday I took the gas pedal and clutch a brake pedal mock ups all back out in preparation for welding and finishing the tunnel. Then start with re-fabricating some of the mock up pieces. Some were made in a quick fashion to test fit and see if it all worked together. Now that I know it does, I can make it look decent.

Also, in regard to the roll bar situation, I discovered I will be able to tie in the roll bar mounts to the frame connectors after all... Although they sit a little ahead of the spring perch, they do sit directly above the frame connector, and that is firmly bolted to the perch, so it will be cohesive in the end. I will make the mount, gussets, and plates, and then weld those to the connectors under the floor so it will bolt through. I want the bar to remain bolt in, as the interior work is much easier to complete nicely since i am keeping a full interior including back seat.

Mark

n altering bar, which isn't out of the question.

n altering bar, which isn't out of the question.