- Jul 7, 2005

- 1,563

- 1,197

- 164

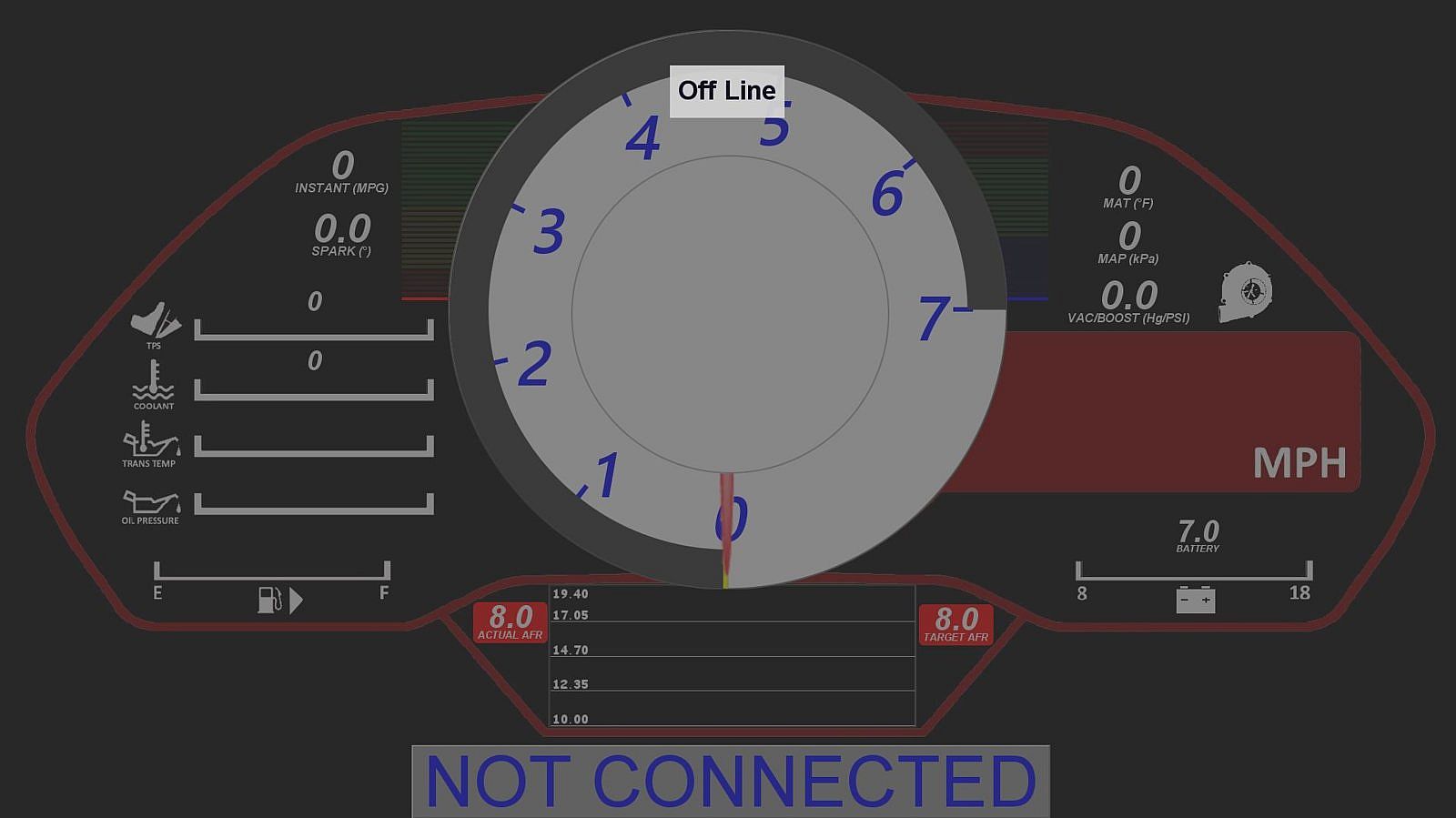

I couldn't find one any wider as I did want one that was wider to fit the cluster better. I also wanted the better screen resolution to since most are 800x600. You can't go taller because it would not fit in the clusterMaybe i asked this already.... but is there an lcd screen that is longer to fill the space more? or would that not work with the design?