MAP/BARO sensor operation and code 22

Revised 24 Oct 2018 add warning about trying to measure the MAP/BARO sensor output with a common multimeter.

On a Speed Density car, the MAP/BARO sensor is connected to the intake manifold and acts to sense the manifold pressure. Lower vacuum inside the intake manifold when combined with more throttle opening measured by the TPS means more airflow through the engine. As airflow increases, fuel flow through the injectors needs to increase to keep the air/fuel ratio where it needs to be. When manifold vacuum increases, the engine is either decelerating or idling, and it needs to reduce the fuel flow through the injectors.

On a Mass Air car, the MAP/BARO sensor vents to open air and actually senses the barometric pressure due to changes in weather and altitude. Its purpose is to set a baseline for the computer to know the barometric pressure. As barometric pressure decreases, it leans out the fuel flow to compensate for less oxygen in the air. When the barometric pressure rises, it increases to add fuel since there is more oxygen in the air. The fuel requirements decrease as altitude increases, since the atmospheric pressure decreases.

Disconnecting the wiring connector from the MAP or BARO sensor will set code 22..

Misconnecting the BARO sensor to vacuum on a Mass Air car will cause the computer to lean out the fuel mixture.

Code 22 or 126 MAP (vacuum) or BARO signal out of range. The MAP or BARO sensor is pretty much the same sensor for both Mass Air & Speed Density cars. The main difference is where it is connected. Mass Air cars vent it to the atmosphere, while Speed Density cars connect it to the intake manifold vacuum. Its purpose is to help set a baseline for the air/fuel mixture by sensing changes in barometric pressure. The MAP or BAP sensor puts out a 5 volt square wave that changes frequency with variations in atmospheric pressure. The base is 154 HZ at 29.92" of mercury - dry sunny day at sea level, about 68-72 degrees. You need an oscilloscope or frequency meter to measure it. There a very few DVM’s with a price tag under $40 that will measure frequency, but there are some out there.

Map sensor wiring:

black/white - ground

orange/white or +5 volts power

white/red signal out.

Measure the +5 volt supply using the orange/white and black/white wires

Measure the signal using the black/white and white/red wires.

The MAP/BARO sensor is mounted on the firewall behind the upper manifold on 86-93 Mustangs.

The Baro or MAP sensor can only be tested using a real frequency meter. The sensor output is a square wave which cannot be accurately measured with a common multimeter. Run the test key on, engine off.. The noise from the ignition system will likely upset the frequency meter. I used a 10 x oscilloscope probe connected from the frequency meter to the MAP/BAP to reduce the jitter in the meter's readout. And oscilloscope is very useful if you have access to one or know of someone who does. With an oscilloscope, you can see the waveform and amplitude.

If it is defective, your air/fuel ratio will be off and the car’s performance & emissions will suffer

Some basic checks you can make to be sure that the sensor is getting power & ground:

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter.

Check the resistance between the black/white wire on the MAP/BARO sensor and then the black/white wire on the EGR and the same wire on the TPS. It should be less than 1 ohm. Next check the resistance between the black/white wire and the negative battery cable. It should be less than 1.5 ohm.

The following power on check requires you to turn the ignition switch to the Run position.

Use a DVM to check for 5 volts on the orange/white wire. If it is missing, look for +5 volts at the orange/white wire on the TPS or EGR sensors. Use the black/white wire for the ground for the DVM.

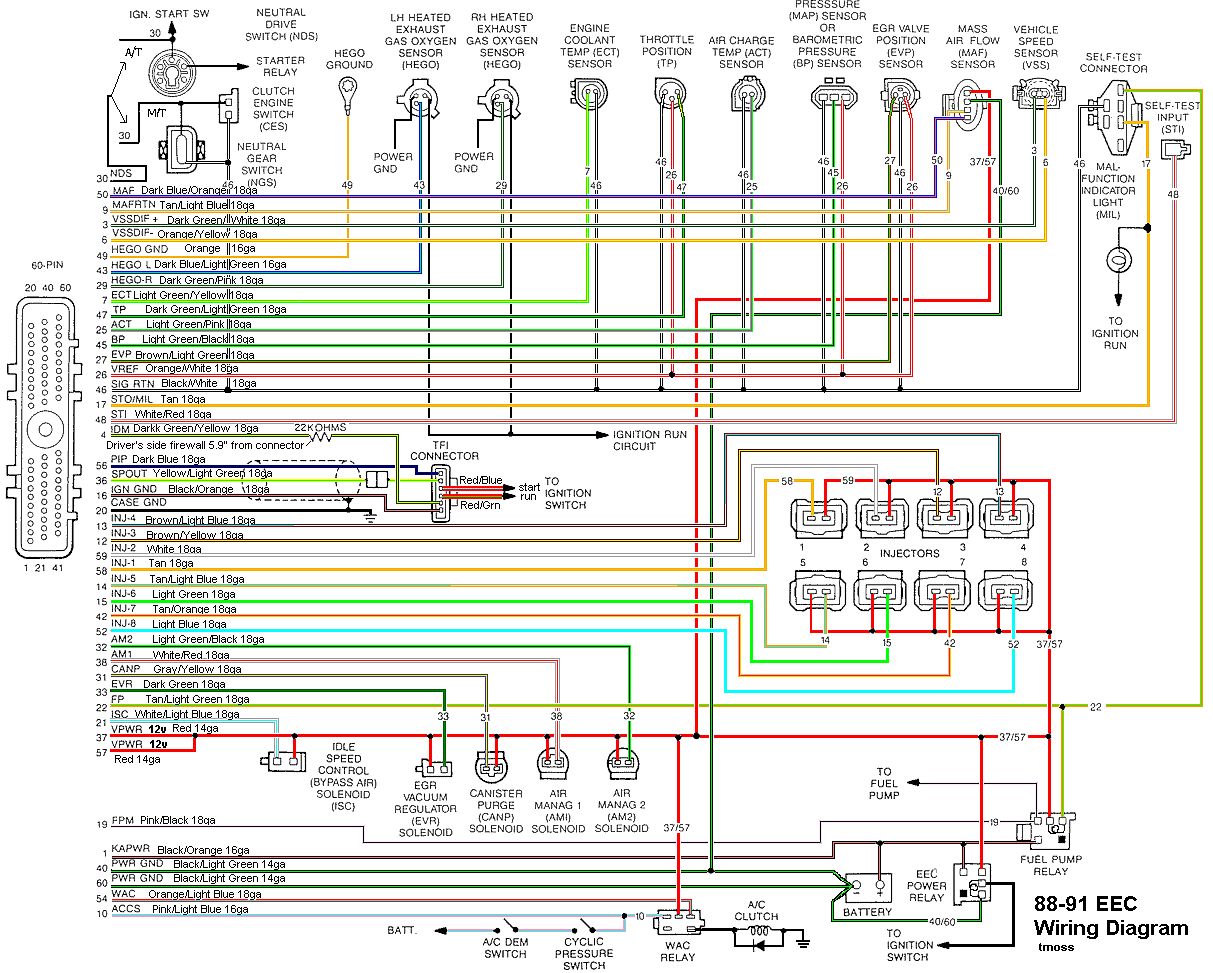

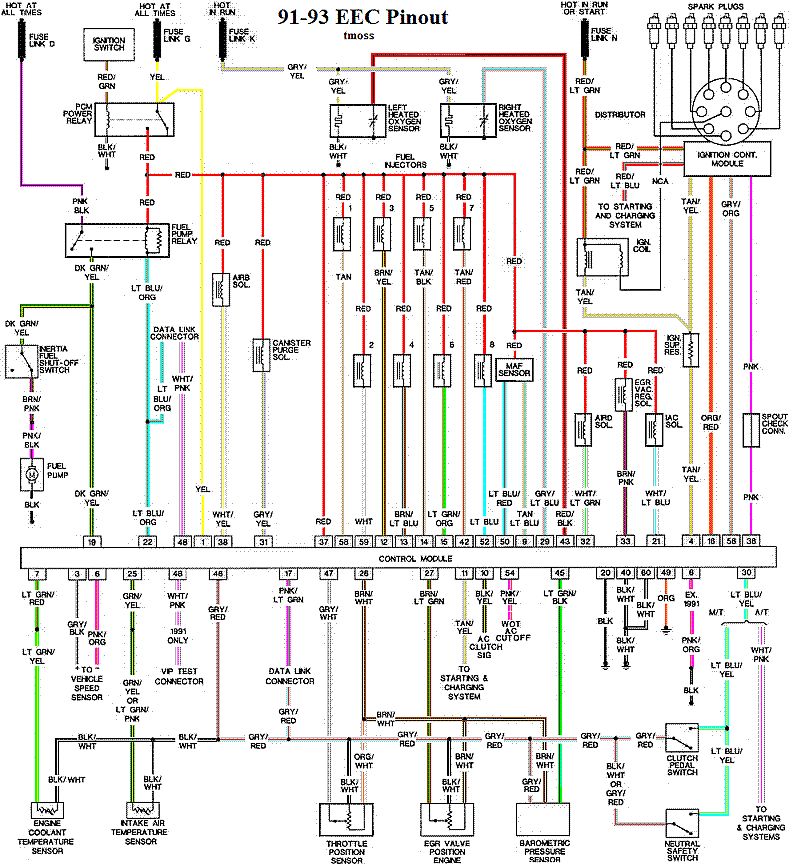

Diagrams courtesy of Tmoss & Stang&2birds

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

Code 66 or 157 MAF below minimum test voltage.

Revised 2 Nov 2019 to add details on MAF testing

Insufficient or no voltage from MAF. Dirty MAF element, bad MAF, bad MAF wiring, missing power to MAF. Check for missing +12 volts on this circuit. Check the two links for a wiring diagram to help you find the red wire for computer power relay switched +12 volts. Check for 12 volts between the red and black wires on the MAF heater (usually pins A & B). while the connector is plugged into the MAF. This may require the use of a couple of safety pins to probe the MAF connector from the back side of it.

Computer wiring harness connector, wire side.

Computer wiring harness connector, computer side.

Diagrams courtesy of Tmoss and Stang&2Birds

ECC Diagram for 88-90 5.0 Mustangs

ECC Diagram for 91-93 5.0 Mustangs

94-95 Diagram for 94-95 5.0 Mustangs[/b]

How the MAF works

There are three parts in a MAF: the heater, the sensor element and the amplifier. The heater heats the MAF sensor element causing the resistance to increase. The amplifier buffers the MAF output signal and has a resistor that is laser trimmed to provide an output range compatible with the computer's load tables. Changes in RPM causes the airflow to increase or decrease, changing the voltage output. The increase of air across the MAF sensor element causes it to cool, allowing more voltage to pass and telling the computer to increase the fuel flow. A decrease in airflow causes the MAF sensor element to get warmer, decreasing the voltage and reducing the fuel flow.

Actually, MAF pins C & D float with reference to ground. The signal output of the MAF is a differential amplifier setup. Pins C & D both carry the output signal, but one pin's output is inverted from the other. The difference in signal between C & D is what the computer's input circuit is looking for. The difference in the two outputs helps cancel out electrical noise generated by the ignition system and other components. Since the noise will be of the same polarity, wave shape and magnitude, the differential input of the computer electronically subtracts it from the signal. Then it passes the signal on to an Analog to Digital converter section inside the computer's CPU chip.

The MAF element is secured by 2 screws & has 1 wiring connector. To clean the element, remove it from the MAF housing and spray it down with electronic parts cleaner or non-inflammable brake parts cleaner (same stuff in a bigger can and cheaper too).

89-90 Model cars: Measure the MAF output at pins C & D on the MAF connector (dark blue/orange and tan/light blue) or at pins 50 & 9 on the computer.

Be sure to measure the sensor output by measuring across the pins and not between the pins and ground.

91-95 Model cars: Measure the MAF output at pins C & D on the MAF connector light blue/red and tan/light blue) or at pins 50 & 9 on the computer.

Be sure to measure the sensor output by measuring across the pins and not between the pins and ground.

MAF output readings: Use the computer connector diagram to help choose the proper pin connection on the computer when measuring the MAF output voltage. The idling voltage check can the done with the voltmeter directly stuck in the backside of the MAF connector.

At idle = approximately .6 volt

20 MPH = approximately 1.10 volt

40 MPH = approximately 1.70 volt

60 MPH = approximately 2.10 volt

If the output of the C&D pins exceeds the specs above, there are two possible problems:

1.) The MAF sensor is defective and needs to be replaced.

2.) The MAF sensor is installed in a different housing than the one it was designed for. The sensor is designed to work with a specific MAF part number or model MAF housing.

Check the resistance of the MAF signal wiring

For the next 2 checks make your measurement with the MAF disconnected from the wiring harness.

Pin D on the MAF wiring harness and pin 50 on the computer (dark blue/orange wire) should be less than 2 ohms. Pin C on the MAF wiring harness and pin 9 on the computer (tan/light blue wire) should be less than 2 ohms.

There should be a minimum of 10K ohms between either pin C or D on the MAF wiring connector and pins A or B.

Reconnect the MAF to the wiring harness and proceed to the next section.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring

http://www.veryuseful.com/mustang/tech/engine/

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel pump, alternator, ignition & A/C wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Computer, actuator & sensor wiring

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Fuse panel layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

Vacuum routing

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring

http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

Ignition switch wiring

Fuel, alternator, A/C and ignition wiring

O2 sensor wiring harness

Vacuum diagram 89-93 Mustangs

HVAC vacuum diagram

TFI module differences & pin out

Fuse box layout

87-92 power window wiring

93 power window wiring

T5 Cutaway showing T5 internal parts

Visual comparison of the Ford Fuel Injectors, picture by TMoss: