I recently changed from head bolts to heads studs, removed the EGR valve and did a smog pump delete. When I got everything back together and started the car, initially there were no problems (1st day) then the next day the car had problems idling. Here's what I've notice:

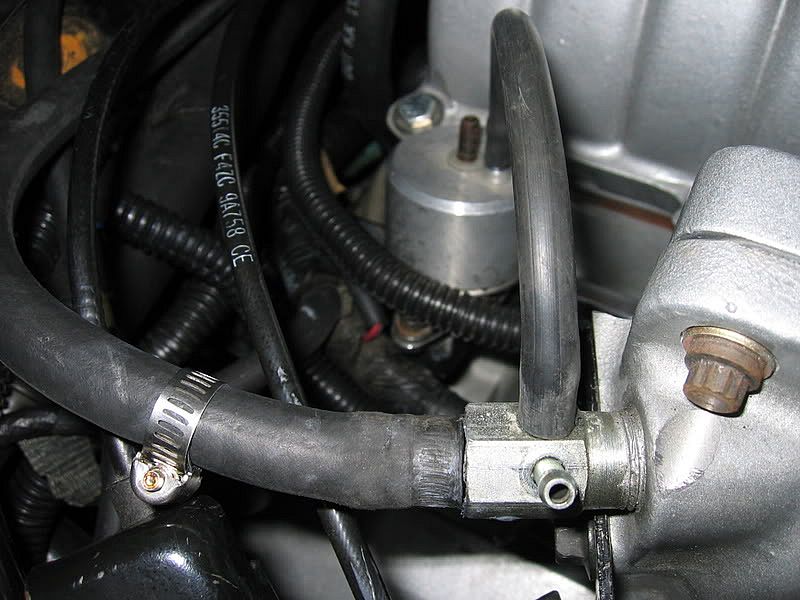

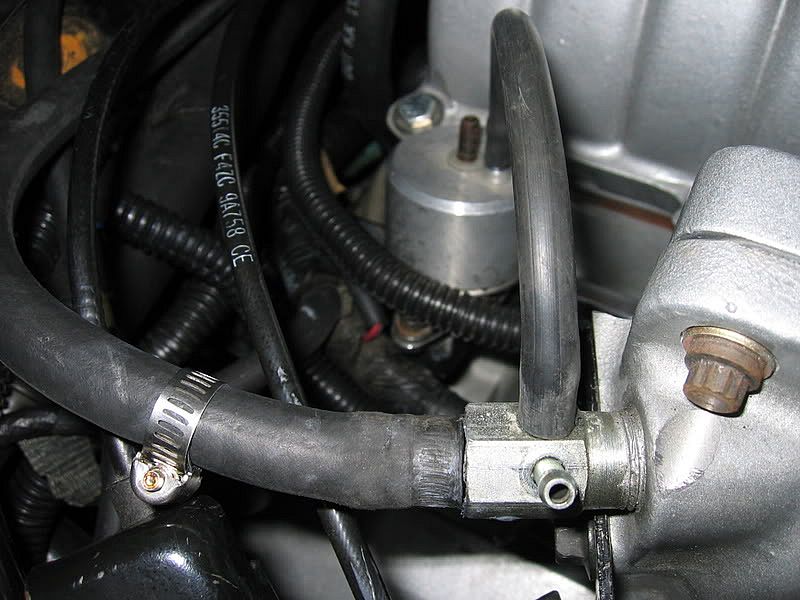

When I disconnect the fuel pressure vacuum hose and remove the cap from the EGR vacuum port (where the red line was connected), the car idles fine but at about 925 rpms (have rpm set at 850). When I reconnect the fuel pressure vacuum hose and cap the EGR vacuum port, while the car is running, the car dies. With the FP hose connected and the EGR vacuum port capped, the car will start but then die. (SEE PICs below)

I drove the car with the FP vacuum hose disconnected and the EGR vacuum uncapped. The car runs very strong, it just wants to die when it comes down to idle.

Diagnostics performed:

Performed vacuum test with both the FP vacuum and EGR cap removed (only way to get the car to idle) and it held steady at 15-15.5 hg.

Sprayed around the intake, TB etc with the vacuum gauge connected to see if there was a vacuum leak - No vacuum change in vacuum, no vacuum leaks.

What could be the problem? This is a mystery to me.

Thanks for any help

When I disconnect the fuel pressure vacuum hose and remove the cap from the EGR vacuum port (where the red line was connected), the car idles fine but at about 925 rpms (have rpm set at 850). When I reconnect the fuel pressure vacuum hose and cap the EGR vacuum port, while the car is running, the car dies. With the FP hose connected and the EGR vacuum port capped, the car will start but then die. (SEE PICs below)

I drove the car with the FP vacuum hose disconnected and the EGR vacuum uncapped. The car runs very strong, it just wants to die when it comes down to idle.

Diagnostics performed:

Performed vacuum test with both the FP vacuum and EGR cap removed (only way to get the car to idle) and it held steady at 15-15.5 hg.

Sprayed around the intake, TB etc with the vacuum gauge connected to see if there was a vacuum leak - No vacuum change in vacuum, no vacuum leaks.

What could be the problem? This is a mystery to me.

Thanks for any help