You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine Car Wont Rev Past 4/4.5k

- Thread starter omarimoe

- Start date

-

Sponsors (?)

Just replace the tps for now..because that code 93 /bad ground on the tps sensor caused the ecu to throw that code 12 for the idle control motor and that's what cause the drop in power. Just set the new tps at 0.50-0.90 volts and you should be okay...and make sure you take both battery cables off for 30 mins before you replace it. Not everyone does this some people just remove the neg cable but i remove both and it works for me. It helps the computer learn faster after adding new sensors plus you have less of a chance of the same codes coming back.

Im betting whoever did the 5 speed swap didnt do it properly. The vss sensor was probably not wired up correctly or at all. Those aod codes will haunt your electrical system until you fix them

I would also double check your oxygen sensor wiring. There are differences between model years, as well as differences between manual and auto. While the plugs will connect, the wiring inside is pinned differently.

If you actually have an A9L, the 39 & 62 codes are invalid.

Code 93 - Throttle linkage binding or bad ISC motor. ISC HO2S not reading Fuel control. The IAB or IAC isn’t controlling the idle. See code 12 if it appears. Clean the IAB and electrical contacts, set the idle speed and TPS.

Setting the TPS at .98 or .99 volt is a Bozo Internet Myth. When the computer powers up and initializes the TPS sensor, whatever it reads is the zero starting point for it. In other words your .98 volt becomes 0 volts and the computer watches for increases in voltage from that point upward.

Setting the TPS: you'll need a good Digital Voltmeter (DVM) to do the job. Set the TPS voltage at .5- 1.1 range. Because of the variables involved with the tolerances of both computer and DVM, I would shoot for somewhere between .6 and 1.0 volts. Unless you have a Fluke or other high grade DVM, the second digit past the decimal point on cheap DVM’s is probably fantasy. Since the computer zeros out the TPS voltage every time it powers up, playing with the settings isn't an effective aid to performance or drivability. The main purpose of checking the TPS is to make sure it isn't way out of range and causing problems.

Wire colors & functions:

Orange/white = 5 volt VREF from the computer

Dark Green/lt green = TPS output to computer

Black/white = Signal ground from computer

TPS troubleshooting steps:

1.) Use the Orange/white & Black white wires to verify the TPS has the correct 5 volts source from the computer.

2.) Use the Dark Green/lt green & Black/white wires to set the TPS base voltage. Try this... All you need is less than 1.0 volt at idle and more than 4.25 at Wide Open Throttle (WOT). You'll need a voltmeter with a 1 or 3 volt low scale to do the job.

The Orange/White wire is the VREF 5 volts from the computer. You use the Dark Green/Lt green wire (TPS signal) and the Black/White wire (TPS ground) to set the TPS. Use a pair of safety pins to probe the TPS connector from the rear of the connector. You may find it a little difficult to make a good connection, but keep trying. Put the safety pins in the Dark Green/Lt green wire and Black/White wire. Make sure the ignition switch is in the Run position but the engine isn't running. Set the voltmeter on the 2 volt range if it doesn’t auto range.

Here’s a TPS tip I got from NoGo50

When you installed the sensor make sure you place it on the peg right and then tighten it down properly. Loosen the back screw a tiny bit so the sensor can pivot and loosen the front screw enough so you can move it just a little in very small increments. I wouldn’t try to adjust it using marks.

(copied from MustangMax, Glendale AZ)

A.) Always adjust the TPS and Idle with the engine at operating temp. Dive it around for a bit if you can and get it nice and warm.

B.) When you probe the leads of the TPS, do not use an engine ground, put the ground probe into the lead of the TPS. You should be connecting both meter probes to the TPS and not one to the TPS and the other to ground.

C.) Always reset the computer whenever you adjust the TPS or clean/change any sensors. I just pull the battery lead for 10 minutes.

D.) The key is to adjust the TPS voltage and reset the computer whenever the idle screw is changed.

The TPS is a variable resistor, must like the volume control knob on a cheap radio. We have all heard them crackle and pop when the volume is adjusted. The TPS sensor has the same problem: wear on the resistor element makes places that create electrical noise. This electrical noise confuses the computer, because it expects to see a smooth increase or decrease as the throttle is opened or closed.

TPS testing: most of the time a failed TPS will set code 23 or 63, but not always. Use either an analog meter or a DVM with an analog bar graph and connect the leads as instructed above. Turn the ignition switch to the Run position, but do not start the engine. Note the voltage with the throttle closed. Slowly open the throttle and watch the voltage increase smoothly, slowly close the throttle and watch the voltage decrease smoothly. If the voltage jumps around and isn’t smooth, the TPS has some worn places in the resistor element. When the throttle is closed, make sure that the voltage is the same as what it was when you started. If it varies more than 10%, the TPS is suspect of being worn in the idle range of its travel.

TPS will not go below 1 volt

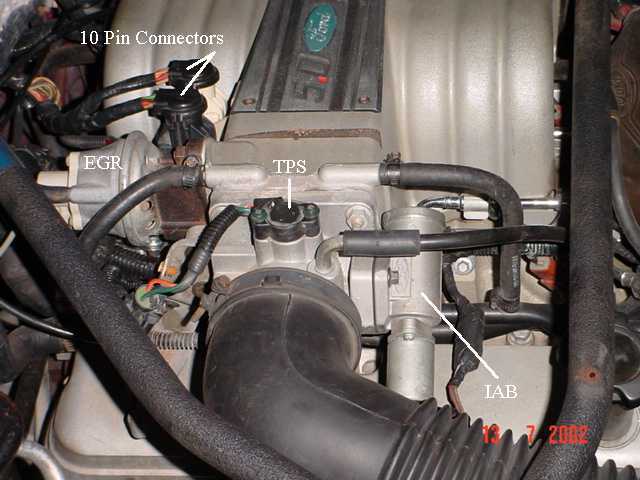

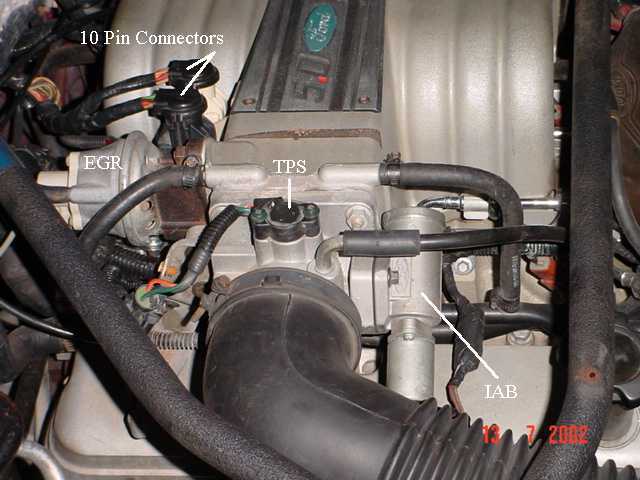

Engine mounted sensor circuit: Check the resistance between the black/white wire on the TPS and battery ground. It should be less than 1.5 ohms. Higher resistance than 1.5 ohms indicates a problem with the 10 pin connector, computer or the splice inside the main harness where the wire from the 10 pin connectors joins the rest of the black/white wire.

See the graphic for the location of the 10 pin connectors:

Diagram courtesy of Tmoss & Stang&2birds

See the graphic for the 10 pin connector circuit layout.

Unplug the white 10 pin connector to do some resistance testing. It is good time to clean the connector pins and examine the connector for corrosion, broken wire or other damage. See http://oldfuelinjection.com/?p=85 for help in this department.

If the resistance on the TPS Black/White wire and pin 1 of the white engine fuel injector harness 10 pin connector, is more than 1.0 ohm, you have bad connection or broken wiring. Repeat the test using the pin 1 of the white body side 10 pin connector and battery ground. You should have less that 1.5 ohm. More than that is a damaged signal ground inside the computer or bad connections or wiring.

Code 93 - Throttle linkage binding or bad ISC motor. ISC HO2S not reading Fuel control. The IAB or IAC isn’t controlling the idle. See code 12 if it appears. Clean the IAB and electrical contacts, set the idle speed and TPS.

Setting the TPS at .98 or .99 volt is a Bozo Internet Myth. When the computer powers up and initializes the TPS sensor, whatever it reads is the zero starting point for it. In other words your .98 volt becomes 0 volts and the computer watches for increases in voltage from that point upward.

Setting the TPS: you'll need a good Digital Voltmeter (DVM) to do the job. Set the TPS voltage at .5- 1.1 range. Because of the variables involved with the tolerances of both computer and DVM, I would shoot for somewhere between .6 and 1.0 volts. Unless you have a Fluke or other high grade DVM, the second digit past the decimal point on cheap DVM’s is probably fantasy. Since the computer zeros out the TPS voltage every time it powers up, playing with the settings isn't an effective aid to performance or drivability. The main purpose of checking the TPS is to make sure it isn't way out of range and causing problems.

Wire colors & functions:

Orange/white = 5 volt VREF from the computer

Dark Green/lt green = TPS output to computer

Black/white = Signal ground from computer

TPS troubleshooting steps:

1.) Use the Orange/white & Black white wires to verify the TPS has the correct 5 volts source from the computer.

2.) Use the Dark Green/lt green & Black/white wires to set the TPS base voltage. Try this... All you need is less than 1.0 volt at idle and more than 4.25 at Wide Open Throttle (WOT). You'll need a voltmeter with a 1 or 3 volt low scale to do the job.

The Orange/White wire is the VREF 5 volts from the computer. You use the Dark Green/Lt green wire (TPS signal) and the Black/White wire (TPS ground) to set the TPS. Use a pair of safety pins to probe the TPS connector from the rear of the connector. You may find it a little difficult to make a good connection, but keep trying. Put the safety pins in the Dark Green/Lt green wire and Black/White wire. Make sure the ignition switch is in the Run position but the engine isn't running. Set the voltmeter on the 2 volt range if it doesn’t auto range.

Here’s a TPS tip I got from NoGo50

When you installed the sensor make sure you place it on the peg right and then tighten it down properly. Loosen the back screw a tiny bit so the sensor can pivot and loosen the front screw enough so you can move it just a little in very small increments. I wouldn’t try to adjust it using marks.

(copied from MustangMax, Glendale AZ)

A.) Always adjust the TPS and Idle with the engine at operating temp. Dive it around for a bit if you can and get it nice and warm.

B.) When you probe the leads of the TPS, do not use an engine ground, put the ground probe into the lead of the TPS. You should be connecting both meter probes to the TPS and not one to the TPS and the other to ground.

C.) Always reset the computer whenever you adjust the TPS or clean/change any sensors. I just pull the battery lead for 10 minutes.

D.) The key is to adjust the TPS voltage and reset the computer whenever the idle screw is changed.

The TPS is a variable resistor, must like the volume control knob on a cheap radio. We have all heard them crackle and pop when the volume is adjusted. The TPS sensor has the same problem: wear on the resistor element makes places that create electrical noise. This electrical noise confuses the computer, because it expects to see a smooth increase or decrease as the throttle is opened or closed.

TPS testing: most of the time a failed TPS will set code 23 or 63, but not always. Use either an analog meter or a DVM with an analog bar graph and connect the leads as instructed above. Turn the ignition switch to the Run position, but do not start the engine. Note the voltage with the throttle closed. Slowly open the throttle and watch the voltage increase smoothly, slowly close the throttle and watch the voltage decrease smoothly. If the voltage jumps around and isn’t smooth, the TPS has some worn places in the resistor element. When the throttle is closed, make sure that the voltage is the same as what it was when you started. If it varies more than 10%, the TPS is suspect of being worn in the idle range of its travel.

TPS will not go below 1 volt

Engine mounted sensor circuit: Check the resistance between the black/white wire on the TPS and battery ground. It should be less than 1.5 ohms. Higher resistance than 1.5 ohms indicates a problem with the 10 pin connector, computer or the splice inside the main harness where the wire from the 10 pin connectors joins the rest of the black/white wire.

See the graphic for the location of the 10 pin connectors:

Diagram courtesy of Tmoss & Stang&2birds

See the graphic for the 10 pin connector circuit layout.

Unplug the white 10 pin connector to do some resistance testing. It is good time to clean the connector pins and examine the connector for corrosion, broken wire or other damage. See http://oldfuelinjection.com/?p=85 for help in this department.

If the resistance on the TPS Black/White wire and pin 1 of the white engine fuel injector harness 10 pin connector, is more than 1.0 ohm, you have bad connection or broken wiring. Repeat the test using the pin 1 of the white body side 10 pin connector and battery ground. You should have less that 1.5 ohm. More than that is a damaged signal ground inside the computer or bad connections or wiring.

Replaced the tps today, reset the idle and reset the computer. Idle smoothed out pretty nice but it didn't help the breaking up at all. Once the car got hot the car did the same thing its been doing and the tach was bouncing all over the place. I also still have the tps and iac codes

Is there anything that could cause a dizzy cap and rotor to crap out? When I first started having this problem I tried a cap and rotor and it fixed the car for like 2 miles. I got the taylor cap and rotor and got a solid 15-20 miles before it started acting up again. When I looked at the new cap and rotor today the copper points on the inside of the cap look like they have big scortch marks on them where the spark jumps from the rotor to cap. I never paid close enough attention to a dizzy cap to know if this is normal or not. Anyway while doing some research I saw that if the tach is jumping all over the place thats almost exclusively related to the dizzy being bad. I think I might try a brand new complete dizzy and if I get no change ill just return it. The one I have been using to test the car is from the junkyard. The guy said it came out of a running car but who knows how accurate that is.

The spark will oxidize the contacts because of the heat created when the spark jumps the gap.

A new distributor might be a good idea at this point. The PIP sensor tend to fail when the engine warms up.

A new distributor might be a good idea at this point. The PIP sensor tend to fail when the engine warms up.

Should I try to clean the contacts with sandpaper or something? Also late model only has 2 complete dizzys. Either an msd or performance distributors. The price is only like a $20 difference but what you you guys recommend?The spark will oxidize the contacts because of the heat created when the spark jumps the gap.

A new distributor might be a good idea at this point. The PIP sensor tend to fail when the engine warms up.

The corrosion won't make much difference. It will happen again after a short time.

Avoid MSD (May Suddenly Die) whenever possible. Get a rebuilt distributor with a lifetime guarantee from you local auto parts supplier. You save money and still get a good product.

Avoid MSD (May Suddenly Die) whenever possible. Get a rebuilt distributor with a lifetime guarantee from you local auto parts supplier. You save money and still get a good product.

The corrosion won't make much difference. It will happen again after a short time.

Avoid MSD (May Suddenly Die) whenever possible. Get a rebuilt distributor with a lifetime guarantee from you local auto parts supplier. You save money and still get a good product.

I would but then I still have to transfer my tfi and everything. I figure if im gunna spend the money I might as well get everything new and not have to worry about something els on the assembly possibly causing the problem. Idk ill check around for prices and see whag I can come up with.

Back again. I was waiting on a brand new reman dizzy. Put it in today and again the car ran great until it got hot then started acting up. I think I have pretty much eliminated the ignition and fuel system components being bad so what do I move onto now? Bad maf? Computer?

Just for refreshers, what is your current configuration? What aftermarket parts and modifications do you have, and what parts have you replaced? It helps to narrow down what hasn't been replaced and what may be suspect.

stock longblock as far as i know, has an edlebrock style aftermarket upper and lower intake, shorty headers with o/r h pipe. i have installed a new 155lph fuel pump with filter, new 19lb injectors with orings, checked and fixed all vacuum leaks, new plugs, wires, cap, rotor, coil, dizzy, tfi, checked all grounds, cleaned maf sensor, new tps. thats all i can think of at the moment. i really dont know what to do next with the car. i feel like its some sensor or something electronic because the car will sit for a few days and then run perfect for about 15-20 mins. then it runs like crap as soon as it gets hot.Just for refreshers, what is your current configuration? What aftermarket parts and modifications do you have, and what parts have you replaced? It helps to narrow down what hasn't been replaced and what may be suspect.

Sometimes the sensors will within limits by a narrow margin. They don't trip a code, but will cause problems.Have you replaced the ECT sensor?

Here's the test path for some help in that area...

Code 21 – ECT sensor out of range. Broken or damaged wiring, bad ECT sensor.

Note that that if the outside air temp is below 50 degrees F that the test for the ECT can be in error. Warm the engine up until you get good hot air from the heater and then dump the codes again.

The ECT sensor has absolutely nothing to do with the temperature gauge. They are different animals. The ECT sensor is normally located it the passenger side front of the engine in the water feed tubes for the heater.

The ACT & ECT have the same thermistor, so the table values are the same

ACT & ECT test data:

Use Pin 46 on the computer for ground for both ECT & ACT to get most accurate readings.

Pin 7 on the computer - ECT signal in. At 176 degrees F it should be .80 volts

Pin 25 on the computer - ACT signal in. At 50 degrees F it should be 3.5 volts. It is a good number if the ACT is mounted in the inlet airbox. If it is mounted in the lower intake manifold, the voltage readings will be lower because of the heat transfer.

Voltages may be measured across the ECT/ACT by probing the connector from the rear. A pair of safety pins may be helpful in doing this. Use care in doing it so that you don't damage the wiring or connector.

Here's the table :

50 degrees F = 3.52 v

68 degrees F = 3.02 v

86 degrees F = 2.62 v

104 degrees F = 2.16 v

122 degrees F = 1.72 v

140 degrees F = 1.35 v

158 degrees F = 1.04 v

176 degrees F = .80 v

194 degrees F = .61

212 degrees F = .47 v

230 degrees F = .36 v

248 degrees F = .28 v

Ohms measures at the computer with the computer disconnected, or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

212 degrees F = 2.07 K ohms

230 degrees F = 1.55 K ohms

248 degrees F = 1.18 k ohms

Diagram courtesy of Tmoss & Stang&2birds

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds

(website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

.

Thanks for the info guys but im done with this car. Im sending it to a shop this week to get it looked at and hopefully to determine what the hell is going on with it. Ill be sure to post back with whatever they find and or whatever the fix is. I consider myself fairly handy with a wrench but diagnostics is def not my calling. I've done what I feel I am capable of with regard to diagnosing the problem and have come up empty. Now its time for someone more knowledgeable and experienced to take over.

Similar threads

- Replies

- 8

- Views

- 825

- Replies

- 5

- Views

- 2K

- Replies

- 8

- Views

- 1K

- Replies

- 23

- Views

- 3K