Seeking help with an electrical draw that just began with my 92 gt in trying to diagnose it with my crappy electrical skills I’ve found that I have a 200milliamp draw that reduces to 110 milliamp when I remove fuse 6 and then reduce to 0 when I remove fuse 11 also so I know both are related to radio but when radio is unplugged I’m still getting a draw I’ve noticed in the past the radio wouldn’t power off with key so I always manually powered it off with out issues till now

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electrical Fox body battery draw

- Thread starter Dizzle92

- Start date

-

Sponsors (?)

Hmmm....does my phone just not show periods anymore? Or have people just stopped using them. That's difficult to read. Why not a single period? There's not even one at the end. Anyway, welcome to the forum. Someone will be in soon to help I'm sure.

Troubleshooting battery drains

Typically it is something draining the battery. Small things like glove box or courtesy lights are often the culprits. If you have an aftermarket stereo or alarm system, it is also suspect.

The ideal method is to disconnect the negative terminal, and connect a Digital Multimeter (DVM) between the negative terminal on the battery and the negative cable. Set the DVM on a low current scale of 2-5 amps if it doesn't auto-range. Watch the current draw, and then start pulling out fuses. When you see a sudden drop in the current, that circuit is the likely culprit.Note that the computer, radio & clock will draw less than 1/10 amp to keep the settings alive.

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf. You will need the Adobe Acrobat viewer which is also a free download – http://www.adobe.com/products/acrobat/readstep2.html

If you can’t find the current drain by pulling fuses, then the alternator is suspect or any aftermarket sound or lighting equipment that may be on the car. Disconnect the alternator output power plug, then disconnect any aftermarket sound or lighting equipment while watching the current on the DVM.

The following are diagrams courtesy of Tmoss & Stang&2birds

5.0 wiring diagram for Fuel Injectors, Sensors, and Actuators

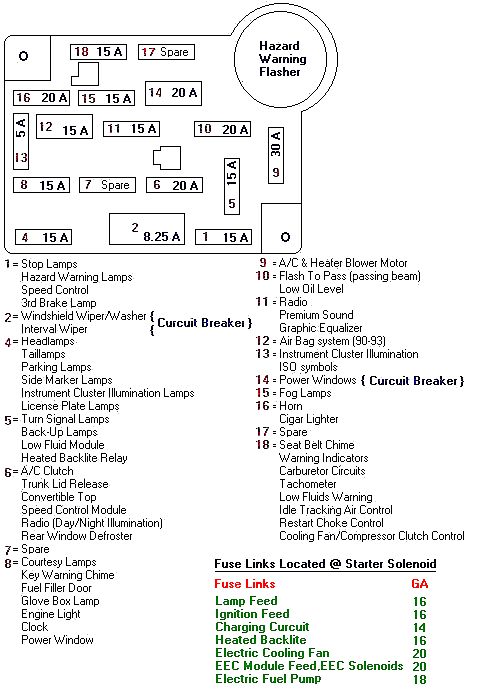

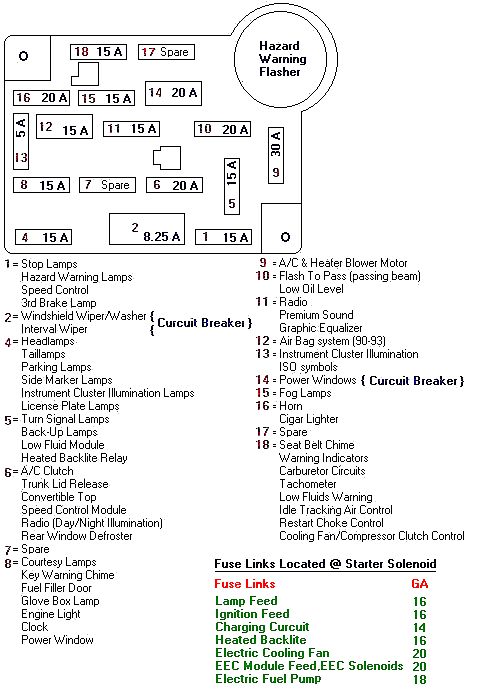

Fuse box layout

Ignition switch wiring

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring; http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

TFI module wiring for 94-95 Mustang GT

http://www.veryuseful.com/mustang/tech/engine/images/Mustang-94-95-IgnitionControlModule.gif

Complete computer, actuator & sensor wiring diagram for 94-95 Mustangs

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

Complete computer, actuator & sensor wiring diagram for 88-90 Mass Air Mustangs

5.0 wiring diagram for Fuel Injectors, Sensors, and Actuators

Ignition switch wiring

O2 sensor wiring harness

Vacuum diagram 89-93 Mustangs

HVAC vacuum diagram

TFI module differences & pin out

Fuse box layout

Mustang 5.0 Lights and Radio schematic, by TMoss:

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxLights-Radio_diag.gif

87-92 power window wiring

93 power window wiring

T5 Cutaway showing T5 internal parts

Visual comparison of the Ford Fuel Injectors, picture by TMoss:

Convertible top motor wiring http://www.veryuseful.com/mustang/tech/engine/images/mustang88VertTopMotorCkt.gif

Engine mounted fuel injector harness

Location of the TPS, IAB, and the 10-pin connectors on a 5.0, picture by TMoss:

Starter circuit

Alternator diagram for 94-95 Mustangs.

Since you have said that you have a low level of proficiency in electrical matters, here's some help before you get started.

Automotive circuits are mostly simple stuff: a power source, a connection path, a control device, a load, and a ground.

The battery/alternator is the positive power source.

The wire and fuses are the connection path.

Control devices are switches, relays and sensors.

A load is a light, motor, solenoid, relay coil or heater element.

In automotive circuits, grounds are the return path so the electrical power can flow from the load to the negative side of the power source.

Electricity flows like water:

Voltage is like pressure,

Current in amps is like volume,

Resistance is like the kink you put in a garden hose to decrease the pressure or volume.

Power is pressure multiplied by volume or voltage multiplied by current (amps)

Digest that, and you just got the first 3 days of Electricity 101.

Use some jumper wires (connection path and ground) to hook up a switch (control device), a battery (power source), a light bulb (load). Now make the light turn on and off with the switch.

That's the electrical lab for the first week of Electricity 101.

For free automotive electrical training, see Automotive Training and Resource Site . Once you are there, select online instruction. I have personally reviewed the material and it is very good. If you are new to automotive electrical troubleshooting, I highly recommend you spend a hour or so going through the material. You'll save at least that much time troubleshooting problems.

Using a Multimeter or DVM

Be careful, most cheap multimeters aren't capable of handling more that 10 amps. When you test current, the wires connected to the meter need to be the same size or larger than the wire that connects device under test to the power source.

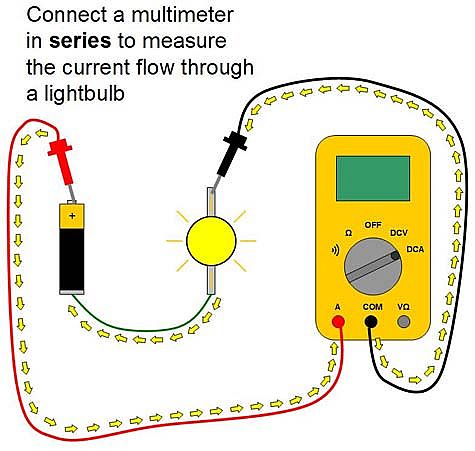

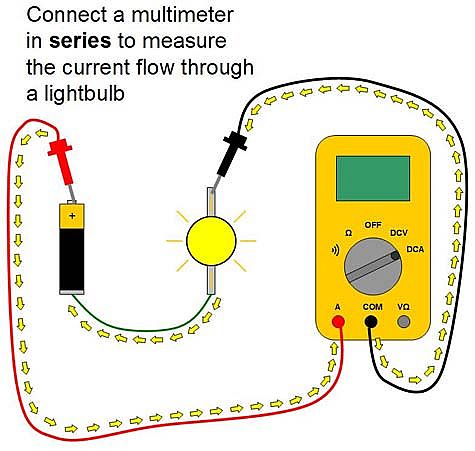

Current (amps) is measured with the meter inline (series) with the device under test.

Most of the high current figures for radiator fans are the surge current figures. Any motor will draw -2-4 times the running current for about 1-2 seconds when it first starts spinning. That's why you use a slow blow fuse or a circuit breaker on a circuit that protects the wiring to a motor. Loads that have a lot of drag will draw higher current for a longer time when they first start up.

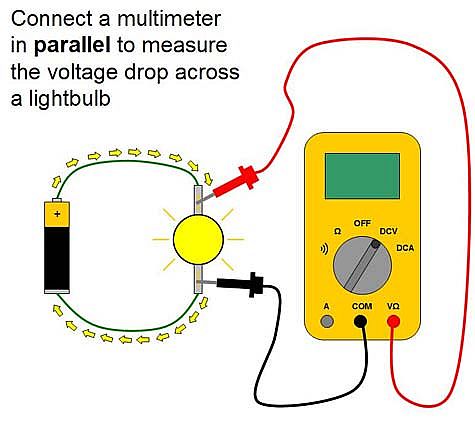

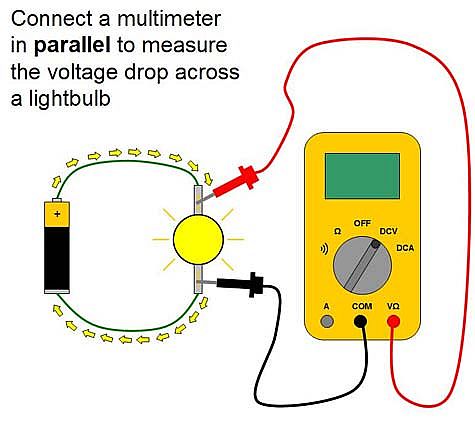

In automotive circuits, Voltage is measured from ground to power input of the device when it is turned on and operating.

Almost every meter has a different method for showing an open circuit. An open circuit is one with a break in it somewhere. That break can be a switch turned off, a fuse blown, a lamp burned out, a bad connector, a damaged circuit board or a cut or burned wire.

Without reading the instruction manual that came with your meter, I would not try to guess what your readings mean.

Step 1.) Find the instruction book that came with your Multimeter or DVM. Read it and familiarize yourself with how it works and how use it. If you lost the book or didn’t get one with it, do a Google search on the web to find the manufacturer’s web site & download a copy of the manual. Remember that while some meters auto-range to find the correct voltage range, the Ohms function ranges are usually set by the selector switch. Most of the resistance testing done in automotive troubleshooting uses the lowest Ohms range possible.

Step 2. ) Make sure that you know what test lead plugs into which jacks on the Multimeter or DVM. There are usually several different jacks on most Multimeter or DVMs, and they have different functions. Make sure that your battery(s) in the Multimeter are good: if you have any doubts, replace the battery(s).

Step 3.) Once you are sure that the Multimeter or DVM is functional and you have the leads plugged into the jacks for Ohms ( the Ω symbol), do some simple measurements to make sure that you know how to use it correctly. Set the switch to the lowest range and touch the leads together: you should not see “nothing” but you should see 0.3-1.0 ohms. Measure a 60 watt light bulb: cold it will measure about 17.5 Ohms. It you measure it while it is hot, the reading will be greater.

Step 4.) Make several test measurements using the ohms function and the DC volts function. Remember all resistance measurements must be done with the power off the circuit. This avoids false readings and possible damage to the ohmmeter.. Repeat steps 3 & 4 until you are sure that you can do it without making any mistakes.

Step 5.) Then see | Repair Guides | Understanding And Troubleshooting Electrical Systems | Basic Electrical Theory | AutoZone.com and carefully study ALL the information under the Heading Chassis Electrical, Basic Electricity – Understanding & Troubleshooting

Step 6.) Apply what you have learned and make the test measurements using the information in the wiring diagrams & my previous posts.

Don't be in too much of a hurry to bolt all the new, pretty, shiny parts together. Take the simple steps now and you will save yourself lots of time and trouble later.

Typically it is something draining the battery. Small things like glove box or courtesy lights are often the culprits. If you have an aftermarket stereo or alarm system, it is also suspect.

The ideal method is to disconnect the negative terminal, and connect a Digital Multimeter (DVM) between the negative terminal on the battery and the negative cable. Set the DVM on a low current scale of 2-5 amps if it doesn't auto-range. Watch the current draw, and then start pulling out fuses. When you see a sudden drop in the current, that circuit is the likely culprit.Note that the computer, radio & clock will draw less than 1/10 amp to keep the settings alive.

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf. You will need the Adobe Acrobat viewer which is also a free download – http://www.adobe.com/products/acrobat/readstep2.html

If you can’t find the current drain by pulling fuses, then the alternator is suspect or any aftermarket sound or lighting equipment that may be on the car. Disconnect the alternator output power plug, then disconnect any aftermarket sound or lighting equipment while watching the current on the DVM.

The following are diagrams courtesy of Tmoss & Stang&2birds

5.0 wiring diagram for Fuel Injectors, Sensors, and Actuators

Fuse box layout

Ignition switch wiring

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring; http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

TFI module wiring for 94-95 Mustang GT

http://www.veryuseful.com/mustang/tech/engine/images/Mustang-94-95-IgnitionControlModule.gif

Complete computer, actuator & sensor wiring diagram for 94-95 Mustangs

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

Complete computer, actuator & sensor wiring diagram for 88-90 Mass Air Mustangs

5.0 wiring diagram for Fuel Injectors, Sensors, and Actuators

Ignition switch wiring

O2 sensor wiring harness

Vacuum diagram 89-93 Mustangs

HVAC vacuum diagram

TFI module differences & pin out

Fuse box layout

Mustang 5.0 Lights and Radio schematic, by TMoss:

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxLights-Radio_diag.gif

87-92 power window wiring

93 power window wiring

T5 Cutaway showing T5 internal parts

Visual comparison of the Ford Fuel Injectors, picture by TMoss:

Convertible top motor wiring http://www.veryuseful.com/mustang/tech/engine/images/mustang88VertTopMotorCkt.gif

Engine mounted fuel injector harness

Location of the TPS, IAB, and the 10-pin connectors on a 5.0, picture by TMoss:

Starter circuit

Alternator diagram for 94-95 Mustangs.

Since you have said that you have a low level of proficiency in electrical matters, here's some help before you get started.

Automotive circuits are mostly simple stuff: a power source, a connection path, a control device, a load, and a ground.

The battery/alternator is the positive power source.

The wire and fuses are the connection path.

Control devices are switches, relays and sensors.

A load is a light, motor, solenoid, relay coil or heater element.

In automotive circuits, grounds are the return path so the electrical power can flow from the load to the negative side of the power source.

Electricity flows like water:

Voltage is like pressure,

Current in amps is like volume,

Resistance is like the kink you put in a garden hose to decrease the pressure or volume.

Power is pressure multiplied by volume or voltage multiplied by current (amps)

Digest that, and you just got the first 3 days of Electricity 101.

Use some jumper wires (connection path and ground) to hook up a switch (control device), a battery (power source), a light bulb (load). Now make the light turn on and off with the switch.

That's the electrical lab for the first week of Electricity 101.

For free automotive electrical training, see Automotive Training and Resource Site . Once you are there, select online instruction. I have personally reviewed the material and it is very good. If you are new to automotive electrical troubleshooting, I highly recommend you spend a hour or so going through the material. You'll save at least that much time troubleshooting problems.

Using a Multimeter or DVM

Be careful, most cheap multimeters aren't capable of handling more that 10 amps. When you test current, the wires connected to the meter need to be the same size or larger than the wire that connects device under test to the power source.

Current (amps) is measured with the meter inline (series) with the device under test.

Most of the high current figures for radiator fans are the surge current figures. Any motor will draw -2-4 times the running current for about 1-2 seconds when it first starts spinning. That's why you use a slow blow fuse or a circuit breaker on a circuit that protects the wiring to a motor. Loads that have a lot of drag will draw higher current for a longer time when they first start up.

In automotive circuits, Voltage is measured from ground to power input of the device when it is turned on and operating.

Almost every meter has a different method for showing an open circuit. An open circuit is one with a break in it somewhere. That break can be a switch turned off, a fuse blown, a lamp burned out, a bad connector, a damaged circuit board or a cut or burned wire.

Without reading the instruction manual that came with your meter, I would not try to guess what your readings mean.

Step 1.) Find the instruction book that came with your Multimeter or DVM. Read it and familiarize yourself with how it works and how use it. If you lost the book or didn’t get one with it, do a Google search on the web to find the manufacturer’s web site & download a copy of the manual. Remember that while some meters auto-range to find the correct voltage range, the Ohms function ranges are usually set by the selector switch. Most of the resistance testing done in automotive troubleshooting uses the lowest Ohms range possible.

Step 2. ) Make sure that you know what test lead plugs into which jacks on the Multimeter or DVM. There are usually several different jacks on most Multimeter or DVMs, and they have different functions. Make sure that your battery(s) in the Multimeter are good: if you have any doubts, replace the battery(s).

Step 3.) Once you are sure that the Multimeter or DVM is functional and you have the leads plugged into the jacks for Ohms ( the Ω symbol), do some simple measurements to make sure that you know how to use it correctly. Set the switch to the lowest range and touch the leads together: you should not see “nothing” but you should see 0.3-1.0 ohms. Measure a 60 watt light bulb: cold it will measure about 17.5 Ohms. It you measure it while it is hot, the reading will be greater.

Step 4.) Make several test measurements using the ohms function and the DC volts function. Remember all resistance measurements must be done with the power off the circuit. This avoids false readings and possible damage to the ohmmeter.. Repeat steps 3 & 4 until you are sure that you can do it without making any mistakes.

Step 5.) Then see | Repair Guides | Understanding And Troubleshooting Electrical Systems | Basic Electrical Theory | AutoZone.com and carefully study ALL the information under the Heading Chassis Electrical, Basic Electricity – Understanding & Troubleshooting

Step 6.) Apply what you have learned and make the test measurements using the information in the wiring diagrams & my previous posts.

Don't be in too much of a hurry to bolt all the new, pretty, shiny parts together. Take the simple steps now and you will save yourself lots of time and trouble later.

Attachments

Last edited:

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 4

- Views

- 1K

- Replies

- 4

- Views

- 400

- Replies

- 93

- Views

- 6K