Ok I've put a rebuit 306 with cobra top end on it. The car has been sitting two years since I cannot find out why it will not restart after turning it off with the key. It will run great and idle as long as you don't turn it off. If I turn it off I have to wait a long time for it to crank back up. I really want to figure this out before I swap a 5 3 in it. My mechanic friend claimed the timing was correct l, bUT it will only run with the tfi almost hitting the thermostat housing. I looked online and that would be a tooth off. Everything under the hood is new except for the starter solenoid. None of the fusible links look burned. All grounds hooked up correctly. I have battery ground hooked to the block. A ground strap hooked on rear lower intake bolt to the firewall and the o2 sensor ground hooked up. Checked the eec ground under the hood and behind kick panel. Checked inertia switch. Changed the computers. Used three of them. Checked relays. My question is that since others online state timing is off since tfi almost touches thermostat housing to run, would that make my car hard to start when hot after turning it off? My friend had his timing light on the balancer and said it was at ten degrees and set correctly. The spout was out when I set timing. He has been a mechanic for over thirty years. Could he have read it wrong? Really need help before I go with an ls swap. Chasing everything else these past years and it end up being the timing will be all the time wasted because I was listening to someone who I thought knew what they were talking about. Sorry for long read.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hard To Start When Hot

- Thread starter warriorpluto

- Start date

-

Sponsors (?)

Step1.) If the gas has been sitting in the fuel tank for more than 3 months, drain, pump out, or siphon out the old gas and put fresh gas in the tank.

Step 2.) Check the timing and adjust if necessary. Carefully read the timing instructions as it addresses the "One tooth off myth".

Step 3.) Do the Cranks OK but no start checklist below when the engine won't start.

Putting the distributor back in and setting the timing.

Note: If you don't have access to a timing light, most of the larger auto parts stores will rent or loan one if you have a credit card or leave a cash deposit.

Revised 28-Jul-2013 to include warning about putting spark plug leads in a different location to attempt a to fix a distributor incorrectly installed.

You can forget about anything beyond this point if you don't have access to a timing light. You will never get the timing set right without one.

Putting the distributor back in is fairly simple. Pull #1 sparkplug, put your finger in the sparkplug hole, crank the engine until you feel compression. Then line up the TDC mark on the balancer with the pointer on the engine block.

The distributor starts out with the #1 plug wire lined up at about 12:00 with you facing it. Align the rotor to about 11:00, since it will turn clockwise as it slides into place.

Align the distributor rotor up with the #1 position marked on the cap, slide the distributor down into the block, (you may have to wiggle the rotor slightly to get the gear to engage) and then note where the rotor is pointing.

If it still lines up with #1 position on the cap, install the clamp and bolt. If not, pull it out and turn 1 tooth forwards or backwards and try again. Put the #1 spark plug back in and tighten it down, put the clamp on the distributor, but don't tighten it too much, as you will have to move the distributor to set the timing. Note that there is no such thing as one tooth off on a 5.0 Mustang if you follow the spark plug wire order on the distributor cap. If it doesn't align perfectly with #1 position, you can turn the distributor until it does. The only problem is that if you are too far one way or the other, you can't turn the distributor enough to get the 10-14 degree optimum timing range. Don't move the wires from the positions shown on the cap on fuel injected engines!!!! The #1 position cast into the cap MUST have the spark plug wire for #1 cylinder in it. Do it differently and the timing for the fuel injectors will be off. The computer uses the PIP sensor to time injector operation by sensing the wide slot in the PIP sensor shutter wheel. If the injector timing of #1 and the firing of #1 do not occur at the right time, the injector timing for all other cylinders will be affected.

Setting the timing:

Paint the mark on the harmonic balancer with paint -choose 10 degrees BTC or 14 degrees BTC or something else if you have NO2 or other power adder. I try to paint TDC red, 10 degrees BTC white and 14 degrees BTC blue.

10 degrees BTC is towards the drivers side marks.

Note: setting the timing beyond the 10 degree mark will give you a little more low speed acceleration. BUT you will need to run 93 octane to avoid pinging and engine damage. Pinging is very hard to hear at full throttle, so it could be present and you would not hear it.

Simplified diagram of what it looks like. Not all the marks are shown for ease of viewing.

ATC ' ' ' ' ' ' ' ' ' '!' ' ' ' ' ' ' ' ' ' BTC

---------------- > Direction of Rotation as viewed standing in front of the engine.

The ' is 2 degrees.

The ! is TDC

The ' is 10 degrees BTC

Set the timing 5 marks BTC. Or if you prefer, 5 marks towards the driver's side to get 10 degrees.

To get 14 degrees, set it 7 marks BTC. Or if you prefer, 7 marks towards the driver's side to get 14 degrees.

The paint marks you make are your friends if you do it correctly. They are much easier to see than the marks machined into the harmonic balancer hub.

At this point hook up all the wires, get out the timing light. Connect timing light up to battery & #1 spark plug. Then start the engine.

Remove the SPOUT connector (do a search if you want a picture of the SPOUT connector) It is the 2 pin rectangular plug on the distributor wiring harness. Only the EFI Mustang engines have a SPOUT. If yours is not EFI, check for a SPOUT: if you don’t find one, skip any instructions regarding the SPOUT

Warning: there are only two places the SPOUT should be when you time the engine. The first place is in your pocket while you are setting the timing and the second is back in the harness when you finish. The little bugger is too easy to lose and too hard to find a replacement.

Start engine, loosen distributor hold down with a 1/2" universal socket. Shine the timing light on the marks and turn the distributor until the mark lines up with the edge of the timing pointer. Tighten down the distributor hold down bolt, Replace the SPOUT connector and you are done.

The HO firing order is 1-3-7-2-6-5-4-8.

Non HO firing order is 1-5-4-2-6-3-7-8

Cranks OK, but No Start Checklist for Fuel Injected 5.0 Mustangs model years 1986-1995

A word about this checklist before you start: it is arranged in a specific order to put the most likely failure items first. That will save you time, energy and money. Start at the top of the list and work your way down. Jumping around will possibly cause you to miss just what you need to see to find and fix the problem. Don’t skip any steps because the next step depends on the last step working correctly.

Revised 15-Sep-2014 to add temporarily bypassing the MSD box if it is present.

All text applies to all models unless stated otherwise.

Note: 94-95 specific changes are in red

1.) Remove push on connector (small red/blue wire) from starter solenoid and turn ignition switch to the Run position. Place car in neutral or Park and set the parking brake. Remove the coil wire from distributor & and hold it 3/8” away from the engine block. Jumper the screw to the big bolt on the starter solenoid that has the battery wire connected to it. You should get a nice fat blue spark.

Most of the items are electrical in nature, so a test light, or even better, a voltmeter, is helpful to be sure they have power to them.

No spark, possible failed items in order of their probability:

A.) MSD, Crane, or other ignition box if present - Bypass it and return to stock configuration if possible. Do this as a temporary measure to eliminate it as a possible problem source.

B.) PIP sensor in distributor. The PIP sensor supplies the timing pulse to trigger the TFI and injectors. A failing PIP sensor will sometimes let the engine start if the SPOUT is removed. See paragraph 5A – Using a noid light will tell if the PIP is working by flashing when the engine is cranking.

C.) TFI module: use a test light to check the TFI module. Place one lead of the test light on the red/green wire on the ignition coil connector and the other lead on the dark green/yellow wire on the ignition coil connector. If the TFI is working properly, the test light will flash when the engine is cranked using the ignition switch.

D.) Coil

E.) No EEC or computer power - EEC or computer relay failure

86-93 models only: EEC relay next to computer - look for 12 volts at the fuel injector red wires.

94-95 models only: EEC or PCM power relay in the constant control relay module. Look for 12 volts at the fuel injector red wires.

Both 86-93 and 94-95 models: No 12 volts with the ignition switch in the run position on the fuel injector red wires. The relay has failed or there is no power coming from the ignition switch. Make sure that there is 12 volts on the red/green wire on the coil before replacing the relay.

F.) No EEC or computer power - fuse or fuse link failure

86-93 models only: Fuse links in wiring harness - look for 12 volts at the fuel injector red wires. All the fuse links live in a bundle up near the starter solenoid. Look for a 20 gauge blue fuse link connected to 2 black/orange 14 gauge wires.

94-95 models only: 20 amp EEC fuse in the engine compartment fuse box. Look for 12 volts at the fuel injector red wires.

G.) Ignition switch - look for 12 volts at the ignition coil red/lt green wire. No 12 volts, blown fuse link or faulty ignition switch. Remove the plastic from around the ignition switch and look for 12 volts on the red/green wire on the ignition switch with it in the Run position. No 12 volts and the ignition switch is faulty. If 12 volts is present in the Run position at the ignition switch but not at the coil, then the fuse or fuse link is blown.

Note: fuses or fuse links blow for a reason. Don’t replace either a fuse or fuse link with one with a larger rating than stock. Doing so invites an electrical fire.

Ignition fuse links may be replaced with an inline fuse holder and 5 amp fuse for troubleshooting purposes.

94-95 models only: Check inside fuse panel for fuse #18 blown – 20 amp [fuse

H.) Missing or loose computer power ground. The computer has its own dedicated power ground that comes off the ground pigtail on the battery ground wire. Due to it's proximity to the battery, it may become corroded by acid fumes from the battery.

In 86-90 model cars, it is a black cylinder about 2 1/2" long by 1" diameter with a black/lt green wire.

In 91-95 model cars it is a black cylinder about 2 1/2" long by 1" diameter with a black/white wire.

You'll find it up next to the starter solenoid where the wire goes into the wiring harness

I.) Computer. Don’t replace the computer just because you don’t understand how it works. Computers seldom fail, it usually is a sensor or wiring problem that causes the problems.

J.) Bad or missing secondary power ground. It is located between the back of the intake manifold and the driver's side firewall. It supplies ground for the alternator, A/C compressor clutch and other electrical accessories such as the gauges.

K.) Engine fires briefly, but dies immediately when the key is released to the Run position. Crank the engine & when it fires off, pull the small push on connector (red/blue wire) off the starter relay (Looks like it is stuck on a screw). Hold the switch in the crank position: if it continues to run there is a problem with either the ignition switch or TFI module. Check for 12 volts at the red/green wire on the coil with the switch in the Run position. Good 12 volts, then replace the TFI. No 12 volts, replace the ignition switch.

Wiring Diagrams:

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring Mustang FAQ - Engine Information Everyone should bookmark this site.

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/91-93_5.0_EEC_Wiring_Diagram.gif

Complete computer, actuator & sensor wiring diagram for 94-95 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/94-95_5.0_EEC_Wiring_Diagram.gif

AutoZone wiring diagrams: You can navigate to the diagrams yourself via Repair Info | AutoZone.com and select the car year, make, model and engine. That will enable you to bring up the wiring diagram for your particular car.

2.) Spark at coil wire, pull #1 plug wire off at the spark plug and check to see spark. No spark, possible failed items in order of their probability: [/b]

A.) Moisture inside distributor – remove cap, dry off & spray with WD40

B.) Distributor cap

C.) Rotor

D.) Spark Plug wires

E.) Coil weak or intermittent - you should see 3/8" fat blue spark with a good coil

3.) Spark at spark plug, but no start.

Next, get a can of starting fluid (ether) from your local auto parts store: costs a $1.30 or so. Then pull the air duct off at the throttle body elbow, open the throttle, and spray the ether in it. Reconnect the air duct and try to start the car. Do not try to start the car without reconnecting the air duct.

Two reasons:

1.) If it backfires, the chance for a serious fire is increased.

2.) On Mass Air cars, the computer needs to measure the MAF flow once the engine starts.

If it starts then, you have a fuel management issue. Continue the checklist with emphasis of fuel related items that follow. If it doesn’t, then it is a computer or timing issue: see Step 4.

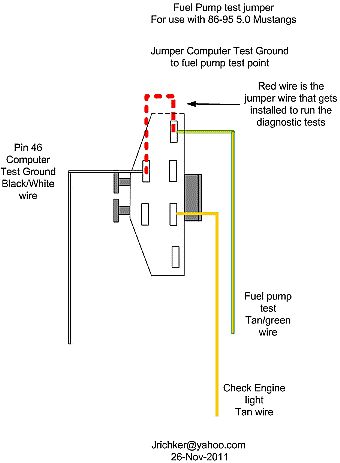

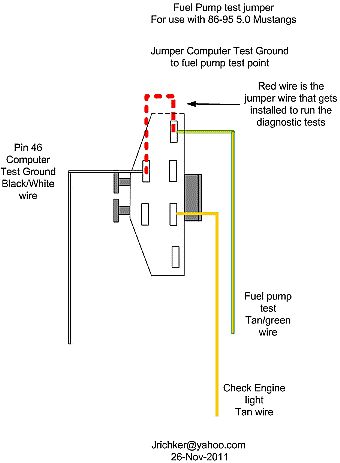

Clue – listen for the fuel pump to prime when you first turn the ignition switch on. It should run for 2-4 seconds and shut off. To trick the fuel pump into running, find the EEC test connector and jump the connector in the Upper RH corner to ground. The EEC connector is near the wiper motor and LH hood hinge.

If the relay & inertia switch are OK, you will have power to the pump. Check fuel pressure – remove the cap from the Schrader valve behind the alternator and depress the core. Fuel should squirt out, catch it in a rag. Beware of fire hazard when you do this. In a pinch, you can use a tire pressure gauge to measure the fuel pressure. It may not be completely accurate, but you will have some clue as to how much pressure you have. If you have any doubts about having sufficient fuel flow/pressure, rent a fuel pressure test gauge from the auto parts store. That will tell you for sure if you have adequate fuel pressure.

4.) No fuel pressure, possible failed items in order of their probability:

A.) Tripped inertia switch – Coupe & hatch cars hide it under the plastic trim covering the driver's side taillight. Use the voltmeter or test light to make sure you have power to both sides of the switch

B.) Fuel pump power relay – located under the driver’s seat in most stangs built before 92. On 92 and later model cars it is located below the Mass Air Flow meter. Look for 12 volts at the Pink/Black wire on the fuel pump relay.

C.) Clogged fuel filter

D.) Failed fuel pump

E.) 86-90 models only: Blown fuse link in wiring harness. Look for 12 volts at the Orange/Lt Blue wire on the fuel pump relay.

91-93 models only Blown fuse link in wiring harness. Look for 12 volts at the Pink/Black wire on the fuel pump relay.

The fuse links for all model years 86-93 live in the wiring harness near the starter solenoid.

94-95 models only: 20 amp fuel pump fuse in the engine compartment fuse box. Look for 12 volts at the Dark green/yellow wire on the constant control relay module.

F.) Engine seem to load up on fuel and may have black smoke at the tailpipe. Fuel pressure regulator failed. Remove the vacuum line from the regulator and inspect for fuel escaping while the pump is running. If fuel is coming out the vacuum port, the regulator has failed. Check the regulator vacuum line for fuel too. Disconnect it from the engine and blow air though it. If you find gas, the regulator has failed.

5.) Fuel pressure OK, the injectors are not firing.

A.) The PIP sensor in the distributor tells the computer when to fire the injectors. A failing PIP sensor will sometimes let the engine start if the SPOUT is removed.

A noid light available from any auto parts store, is one way to test the injector circuit to see if the injectors are firing. The noid light plugs into the fuel injector harness in place of any easily accessible injector. Plug it in and try to start the engine: it will flash if the injector is firing.

I like to use an old injector with compressed air applied to the injector where the fuel rail would normally connect. I hook the whole thing up, apply compressed air to the injector and stick it in a paper cup of soapy water. When the engine cranks with the ignition switch on, if the injector fires, it makes bubbles. Cheap if you have the stuff laying around, and works good too.

B.) Pull an injector wire connector off and look for 12 volts on the red wire when the ignition switch is on.

C.) No power, then look for problems with the 10 pin connecter (salt & pepper shakers at the rear of the upper manifold).

See the graphic for the 10 pin connector circuit layout.

The injector power pin is the VPWR pin in the black 10 pin connector.

D.) No power and the 10 pin connections are good: look for broken wiring between the orange/black wire on the EEC relay and the red wire for the 10 pin connectors.

E.) TPS voltage exceeds 3.7 volts with the throttle closed. This will shut off the injectors, since the computer uses this strategy to clear a flooded engine. Use a DVM, a pair of safety pins, and probe the black/white and green wires to measure the TPS voltage.

On a 94-95 Mustang, probe the black/white and grey/white wires to measure the TPS voltage.

It should be .5-.1.0 volts with the key on, engine not running. Note that if the black/white wire (signal ground) has a bad connection, you will get some strange readings. Make a second measurement using the battery post as the ground to eliminate any ground problems. If the readings are different by more than 5%, you may have a high resistance condition in the black/white signal ground circuit.

6.) Spark & fuel pressure OK.

A.) Failed IAB or improperly set base idle (no airflow to start engine). Press the throttle ¼ way down and try to start the car. See the "Surging Idle Checklist for help with all your idle/stall problems.

B.) Failed computer (not very likely)

C.) Engine ignition or cam timing off: only likely if the engine has been worked on recently. If you removed the distributor, there is a good probability that you installed it 180 degrees out of time.

D.) Firing order off: HO & 351 use a different firing order from the non HO engines.

HO & 351W 1-3-7-2-6-5-4-8

Non HO 1-5-4-2-6-3-7-8

E.) No start when hot - Press the throttle to the floor & try starting it, if you get this far. If it starts, replace the ECT.

F. ) Engine that has had the heads off or valves adjusted. Do a compression test to make sure the valves are not adjusted too tight. You should have a minimum of 90 PSI on a cold engine.

Step 2.) Check the timing and adjust if necessary. Carefully read the timing instructions as it addresses the "One tooth off myth".

Step 3.) Do the Cranks OK but no start checklist below when the engine won't start.

Putting the distributor back in and setting the timing.

Note: If you don't have access to a timing light, most of the larger auto parts stores will rent or loan one if you have a credit card or leave a cash deposit.

Revised 28-Jul-2013 to include warning about putting spark plug leads in a different location to attempt a to fix a distributor incorrectly installed.

You can forget about anything beyond this point if you don't have access to a timing light. You will never get the timing set right without one.

Putting the distributor back in is fairly simple. Pull #1 sparkplug, put your finger in the sparkplug hole, crank the engine until you feel compression. Then line up the TDC mark on the balancer with the pointer on the engine block.

The distributor starts out with the #1 plug wire lined up at about 12:00 with you facing it. Align the rotor to about 11:00, since it will turn clockwise as it slides into place.

Align the distributor rotor up with the #1 position marked on the cap, slide the distributor down into the block, (you may have to wiggle the rotor slightly to get the gear to engage) and then note where the rotor is pointing.

If it still lines up with #1 position on the cap, install the clamp and bolt. If not, pull it out and turn 1 tooth forwards or backwards and try again. Put the #1 spark plug back in and tighten it down, put the clamp on the distributor, but don't tighten it too much, as you will have to move the distributor to set the timing. Note that there is no such thing as one tooth off on a 5.0 Mustang if you follow the spark plug wire order on the distributor cap. If it doesn't align perfectly with #1 position, you can turn the distributor until it does. The only problem is that if you are too far one way or the other, you can't turn the distributor enough to get the 10-14 degree optimum timing range. Don't move the wires from the positions shown on the cap on fuel injected engines!!!! The #1 position cast into the cap MUST have the spark plug wire for #1 cylinder in it. Do it differently and the timing for the fuel injectors will be off. The computer uses the PIP sensor to time injector operation by sensing the wide slot in the PIP sensor shutter wheel. If the injector timing of #1 and the firing of #1 do not occur at the right time, the injector timing for all other cylinders will be affected.

Setting the timing:

Paint the mark on the harmonic balancer with paint -choose 10 degrees BTC or 14 degrees BTC or something else if you have NO2 or other power adder. I try to paint TDC red, 10 degrees BTC white and 14 degrees BTC blue.

10 degrees BTC is towards the drivers side marks.

Note: setting the timing beyond the 10 degree mark will give you a little more low speed acceleration. BUT you will need to run 93 octane to avoid pinging and engine damage. Pinging is very hard to hear at full throttle, so it could be present and you would not hear it.

Simplified diagram of what it looks like. Not all the marks are shown for ease of viewing.

ATC ' ' ' ' ' ' ' ' ' '!' ' ' ' ' ' ' ' ' ' BTC

---------------- > Direction of Rotation as viewed standing in front of the engine.

The ' is 2 degrees.

The ! is TDC

The ' is 10 degrees BTC

Set the timing 5 marks BTC. Or if you prefer, 5 marks towards the driver's side to get 10 degrees.

To get 14 degrees, set it 7 marks BTC. Or if you prefer, 7 marks towards the driver's side to get 14 degrees.

The paint marks you make are your friends if you do it correctly. They are much easier to see than the marks machined into the harmonic balancer hub.

At this point hook up all the wires, get out the timing light. Connect timing light up to battery & #1 spark plug. Then start the engine.

Remove the SPOUT connector (do a search if you want a picture of the SPOUT connector) It is the 2 pin rectangular plug on the distributor wiring harness. Only the EFI Mustang engines have a SPOUT. If yours is not EFI, check for a SPOUT: if you don’t find one, skip any instructions regarding the SPOUT

Warning: there are only two places the SPOUT should be when you time the engine. The first place is in your pocket while you are setting the timing and the second is back in the harness when you finish. The little bugger is too easy to lose and too hard to find a replacement.

Start engine, loosen distributor hold down with a 1/2" universal socket. Shine the timing light on the marks and turn the distributor until the mark lines up with the edge of the timing pointer. Tighten down the distributor hold down bolt, Replace the SPOUT connector and you are done.

The HO firing order is 1-3-7-2-6-5-4-8.

Non HO firing order is 1-5-4-2-6-3-7-8

Cranks OK, but No Start Checklist for Fuel Injected 5.0 Mustangs model years 1986-1995

A word about this checklist before you start: it is arranged in a specific order to put the most likely failure items first. That will save you time, energy and money. Start at the top of the list and work your way down. Jumping around will possibly cause you to miss just what you need to see to find and fix the problem. Don’t skip any steps because the next step depends on the last step working correctly.

Revised 15-Sep-2014 to add temporarily bypassing the MSD box if it is present.

All text applies to all models unless stated otherwise.

Note: 94-95 specific changes are in red

1.) Remove push on connector (small red/blue wire) from starter solenoid and turn ignition switch to the Run position. Place car in neutral or Park and set the parking brake. Remove the coil wire from distributor & and hold it 3/8” away from the engine block. Jumper the screw to the big bolt on the starter solenoid that has the battery wire connected to it. You should get a nice fat blue spark.

Most of the items are electrical in nature, so a test light, or even better, a voltmeter, is helpful to be sure they have power to them.

No spark, possible failed items in order of their probability:

A.) MSD, Crane, or other ignition box if present - Bypass it and return to stock configuration if possible. Do this as a temporary measure to eliminate it as a possible problem source.

B.) PIP sensor in distributor. The PIP sensor supplies the timing pulse to trigger the TFI and injectors. A failing PIP sensor will sometimes let the engine start if the SPOUT is removed. See paragraph 5A – Using a noid light will tell if the PIP is working by flashing when the engine is cranking.

C.) TFI module: use a test light to check the TFI module. Place one lead of the test light on the red/green wire on the ignition coil connector and the other lead on the dark green/yellow wire on the ignition coil connector. If the TFI is working properly, the test light will flash when the engine is cranked using the ignition switch.

D.) Coil

E.) No EEC or computer power - EEC or computer relay failure

86-93 models only: EEC relay next to computer - look for 12 volts at the fuel injector red wires.

94-95 models only: EEC or PCM power relay in the constant control relay module. Look for 12 volts at the fuel injector red wires.

Both 86-93 and 94-95 models: No 12 volts with the ignition switch in the run position on the fuel injector red wires. The relay has failed or there is no power coming from the ignition switch. Make sure that there is 12 volts on the red/green wire on the coil before replacing the relay.

F.) No EEC or computer power - fuse or fuse link failure

86-93 models only: Fuse links in wiring harness - look for 12 volts at the fuel injector red wires. All the fuse links live in a bundle up near the starter solenoid. Look for a 20 gauge blue fuse link connected to 2 black/orange 14 gauge wires.

94-95 models only: 20 amp EEC fuse in the engine compartment fuse box. Look for 12 volts at the fuel injector red wires.

G.) Ignition switch - look for 12 volts at the ignition coil red/lt green wire. No 12 volts, blown fuse link or faulty ignition switch. Remove the plastic from around the ignition switch and look for 12 volts on the red/green wire on the ignition switch with it in the Run position. No 12 volts and the ignition switch is faulty. If 12 volts is present in the Run position at the ignition switch but not at the coil, then the fuse or fuse link is blown.

Note: fuses or fuse links blow for a reason. Don’t replace either a fuse or fuse link with one with a larger rating than stock. Doing so invites an electrical fire.

Ignition fuse links may be replaced with an inline fuse holder and 5 amp fuse for troubleshooting purposes.

94-95 models only: Check inside fuse panel for fuse #18 blown – 20 amp [fuse

H.) Missing or loose computer power ground. The computer has its own dedicated power ground that comes off the ground pigtail on the battery ground wire. Due to it's proximity to the battery, it may become corroded by acid fumes from the battery.

In 86-90 model cars, it is a black cylinder about 2 1/2" long by 1" diameter with a black/lt green wire.

In 91-95 model cars it is a black cylinder about 2 1/2" long by 1" diameter with a black/white wire.

You'll find it up next to the starter solenoid where the wire goes into the wiring harness

I.) Computer. Don’t replace the computer just because you don’t understand how it works. Computers seldom fail, it usually is a sensor or wiring problem that causes the problems.

J.) Bad or missing secondary power ground. It is located between the back of the intake manifold and the driver's side firewall. It supplies ground for the alternator, A/C compressor clutch and other electrical accessories such as the gauges.

K.) Engine fires briefly, but dies immediately when the key is released to the Run position. Crank the engine & when it fires off, pull the small push on connector (red/blue wire) off the starter relay (Looks like it is stuck on a screw). Hold the switch in the crank position: if it continues to run there is a problem with either the ignition switch or TFI module. Check for 12 volts at the red/green wire on the coil with the switch in the Run position. Good 12 volts, then replace the TFI. No 12 volts, replace the ignition switch.

Wiring Diagrams:

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring Mustang FAQ - Engine Information Everyone should bookmark this site.

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/91-93_5.0_EEC_Wiring_Diagram.gif

Complete computer, actuator & sensor wiring diagram for 94-95 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/94-95_5.0_EEC_Wiring_Diagram.gif

AutoZone wiring diagrams: You can navigate to the diagrams yourself via Repair Info | AutoZone.com and select the car year, make, model and engine. That will enable you to bring up the wiring diagram for your particular car.

2.) Spark at coil wire, pull #1 plug wire off at the spark plug and check to see spark. No spark, possible failed items in order of their probability: [/b]

A.) Moisture inside distributor – remove cap, dry off & spray with WD40

B.) Distributor cap

C.) Rotor

D.) Spark Plug wires

E.) Coil weak or intermittent - you should see 3/8" fat blue spark with a good coil

3.) Spark at spark plug, but no start.

Next, get a can of starting fluid (ether) from your local auto parts store: costs a $1.30 or so. Then pull the air duct off at the throttle body elbow, open the throttle, and spray the ether in it. Reconnect the air duct and try to start the car. Do not try to start the car without reconnecting the air duct.

Two reasons:

1.) If it backfires, the chance for a serious fire is increased.

2.) On Mass Air cars, the computer needs to measure the MAF flow once the engine starts.

If it starts then, you have a fuel management issue. Continue the checklist with emphasis of fuel related items that follow. If it doesn’t, then it is a computer or timing issue: see Step 4.

Clue – listen for the fuel pump to prime when you first turn the ignition switch on. It should run for 2-4 seconds and shut off. To trick the fuel pump into running, find the EEC test connector and jump the connector in the Upper RH corner to ground. The EEC connector is near the wiper motor and LH hood hinge.

If the relay & inertia switch are OK, you will have power to the pump. Check fuel pressure – remove the cap from the Schrader valve behind the alternator and depress the core. Fuel should squirt out, catch it in a rag. Beware of fire hazard when you do this. In a pinch, you can use a tire pressure gauge to measure the fuel pressure. It may not be completely accurate, but you will have some clue as to how much pressure you have. If you have any doubts about having sufficient fuel flow/pressure, rent a fuel pressure test gauge from the auto parts store. That will tell you for sure if you have adequate fuel pressure.

4.) No fuel pressure, possible failed items in order of their probability:

A.) Tripped inertia switch – Coupe & hatch cars hide it under the plastic trim covering the driver's side taillight. Use the voltmeter or test light to make sure you have power to both sides of the switch

B.) Fuel pump power relay – located under the driver’s seat in most stangs built before 92. On 92 and later model cars it is located below the Mass Air Flow meter. Look for 12 volts at the Pink/Black wire on the fuel pump relay.

C.) Clogged fuel filter

D.) Failed fuel pump

E.) 86-90 models only: Blown fuse link in wiring harness. Look for 12 volts at the Orange/Lt Blue wire on the fuel pump relay.

91-93 models only Blown fuse link in wiring harness. Look for 12 volts at the Pink/Black wire on the fuel pump relay.

The fuse links for all model years 86-93 live in the wiring harness near the starter solenoid.

94-95 models only: 20 amp fuel pump fuse in the engine compartment fuse box. Look for 12 volts at the Dark green/yellow wire on the constant control relay module.

F.) Engine seem to load up on fuel and may have black smoke at the tailpipe. Fuel pressure regulator failed. Remove the vacuum line from the regulator and inspect for fuel escaping while the pump is running. If fuel is coming out the vacuum port, the regulator has failed. Check the regulator vacuum line for fuel too. Disconnect it from the engine and blow air though it. If you find gas, the regulator has failed.

5.) Fuel pressure OK, the injectors are not firing.

A.) The PIP sensor in the distributor tells the computer when to fire the injectors. A failing PIP sensor will sometimes let the engine start if the SPOUT is removed.

A noid light available from any auto parts store, is one way to test the injector circuit to see if the injectors are firing. The noid light plugs into the fuel injector harness in place of any easily accessible injector. Plug it in and try to start the engine: it will flash if the injector is firing.

I like to use an old injector with compressed air applied to the injector where the fuel rail would normally connect. I hook the whole thing up, apply compressed air to the injector and stick it in a paper cup of soapy water. When the engine cranks with the ignition switch on, if the injector fires, it makes bubbles. Cheap if you have the stuff laying around, and works good too.

B.) Pull an injector wire connector off and look for 12 volts on the red wire when the ignition switch is on.

C.) No power, then look for problems with the 10 pin connecter (salt & pepper shakers at the rear of the upper manifold).

See the graphic for the 10 pin connector circuit layout.

The injector power pin is the VPWR pin in the black 10 pin connector.

D.) No power and the 10 pin connections are good: look for broken wiring between the orange/black wire on the EEC relay and the red wire for the 10 pin connectors.

E.) TPS voltage exceeds 3.7 volts with the throttle closed. This will shut off the injectors, since the computer uses this strategy to clear a flooded engine. Use a DVM, a pair of safety pins, and probe the black/white and green wires to measure the TPS voltage.

On a 94-95 Mustang, probe the black/white and grey/white wires to measure the TPS voltage.

It should be .5-.1.0 volts with the key on, engine not running. Note that if the black/white wire (signal ground) has a bad connection, you will get some strange readings. Make a second measurement using the battery post as the ground to eliminate any ground problems. If the readings are different by more than 5%, you may have a high resistance condition in the black/white signal ground circuit.

6.) Spark & fuel pressure OK.

A.) Failed IAB or improperly set base idle (no airflow to start engine). Press the throttle ¼ way down and try to start the car. See the "Surging Idle Checklist for help with all your idle/stall problems.

B.) Failed computer (not very likely)

C.) Engine ignition or cam timing off: only likely if the engine has been worked on recently. If you removed the distributor, there is a good probability that you installed it 180 degrees out of time.

D.) Firing order off: HO & 351 use a different firing order from the non HO engines.

HO & 351W 1-3-7-2-6-5-4-8

Non HO 1-5-4-2-6-3-7-8

E.) No start when hot - Press the throttle to the floor & try starting it, if you get this far. If it starts, replace the ECT.

F. ) Engine that has had the heads off or valves adjusted. Do a compression test to make sure the valves are not adjusted too tight. You should have a minimum of 90 PSI on a cold engine.

Thanks for the checklist. I'll try to set the timing again, but first I'll have to locate a timing Light. It's my first car, but has been sitting up since 2007. I own a 99 trans am amd envoy denali now. Really anxious to drive it having so many problems. First two engines I got from mps auto salvage were bad. Big waste of time and money and is the reason my car has been down so long. Ordered a rebuilt short block from mabbco which runs great, now facing maybe electrical or timing problems. Need to nip this in a bud this year. I'll update with my findings tomorrow. First time using timing light

OneWheelPeel

Active Member

Do you wait for the car to get to operating temp before turning it off? If so I would check the tfi. When it gets old the heat starts to mess it up until it cools off again.

Yes it sits and idle for twenty minutes no problem. Until I turn it off. Changed tfi. Used five old, new ,junkyard and oem tfi modules. No change. When I tell you I've changed things under the hood and everything is new as far as sensors and components go it's new. Distributor, Balancer, air temp sensor, eec coolant temp sensor for computer, new balancer. New double row timing set aligned dot to dot. New map sensor. Changed things more than five times I know trying to diagnose what could be wrong. Compression good and fuel pressure. Adjustable regulator adjusted to specs and confirmed through fuel pressure gauge. Have spark. I'll change coil tomorrow just to make sure everything super new. I've changed that one time

Once heat soak sets into a TFI module it can cause a loss of spark. make sure you are using dielectric grease when you install the TFI for proper function. When the pip sensor in my distributor went bad it would leave me sitting at the store randomly, changed tfi twice chasing that one..... Is the distributor new or used???

Why the LS swap? and why bother getting a engine running if you are going to swap it out anyway?

Why the LS swap? and why bother getting a engine running if you are going to swap it out anyway?

If I can't get it running I was going to swap it out since switching over to a 351w would be near the same price as swapping a 5.3. Distributor is new. I had three sitting around. Same thing

All parts were bought and after still chasing, I swapped from a friend's wrecked Mustang that's currently sitting inside the shop. That's how I'm able to get a hold of so much stuff

Get the car up to operating temp, [fully warmed up] shut it off so it wont restart. pull a spark plug wire and check to see that you have spark, if you do we can rule out the pip and tfi [ well almost they could still be problematic] if you don't have spark then we will go from there.

I tested all of that. I definitely have spark. Also injector pulse with noid light. Would a fuel pump do that? Should I change it out?

Also wanted to add I have an 88 California harness. My car is an 87. Maf connector was converted for standard plug by solder.

Don't throw parts at it, that will just piss you off. If your sure that you have spark once the engine is heat soaked AND THE CAR WON'T RESTART and you still have spark. Then you need to check timing, also check that the ect sensor is working.I tested all of that. I definitely have spark. Also injector pulse with noid light. Would a fuel pump do that? Should I change it out?

I really do hate to throw parts at it. I'm going to verify timing today with a light. Really itching to change that ect sensor again. I got it from advance and all they carry is Chinese junk. I think they are worse than autozone now. Maybe it was possible to get a bad sensor two times?Don't throw parts at it, that will just **** you off. If your sure that you have spark once the engine is heat soaked AND THE CAR WON'T RESTART and you still have spark. Then you need to check timing, also check that the ect sensor is working.

My wife works at advanced and I'm happy to say since they bought out carquest (recently) they now offer really good parts if you buy there premium stuff. I agree there parts were crap up until the mergeI really do hate to throw parts at it. I'm going to verify timing today with a light. Really itching to change that ect sensor again. I got it from advance and all they carry is Chinese junk. I think they are worse than autozone now. Maybe it was possible to get a bad sensor two times?

I tested all of that. I definitely have spark. Also injector pulse with noid light. Would a fuel pump do that? Should I change it out?

You can find out by hooking a pressure gauge up to the fuel rail and see what's going on there.

OneWheelPeel

Active Member

If you have an extra one you could try. My fuel pump would cut out while driving for a while and would start up after I let it sit for a while. The only reason I thought to change it out was because I couldn't hear it running anymore when I turned the key. Everyone told me it was a tfi so in your case it could be the fuel pump too. Check for fuel as you try to start it back up.I tested all of that. I definitely have spark. Also injector pulse with noid light. Would a fuel pump do that? Should I change it out?

i checked again today on the fuel pressure and it has pressure when it will not start. also the fuel pump primes. i really wish i had some shelter to work on my car. the place its sitting now has baby snakes crawling under the cars and spiders. every time i go work on it i have to fight those and little insects that fall out of the tree. i looked at a couple of videos on how to use a timing light on sbf so ill do that tomorrow. my friend will be bringing his finally. ill change the fuel pump out anyway since my gauge isnt working.

i checked again today on the fuel pressure and it has pressure when it will not start. also the fuel pump primes. i really wish i had some shelter to work on my car. the place its sitting now has baby snakes crawling under the cars and spiders. every time i go work on it i have to fight those and little insects that fall out of the tree. i looked at a couple of videos on how to use a timing light on sbf so ill do that tomorrow. my friend will be bringing his finally. ill change the fuel pump out anyway since my gauge isnt working.

Read the fuel gauge troubleshooter below before you change the fuel tank sender...

Fuel Quantity gauge troubleshooting 87-93 Mustangs

The red/yellow wire (power supply to gauge & sender) should have 12 volts when the ignition is in the start or Run position.

Troubleshooting the gauge and sender circuit:

Since the sender uses a variable resistor, sum the resistor values of 22 Ohms (empty value) & 145 Ohms (full value). That gets you 167, which you divide by 2: that gets you 83.5. So in theory, 83.5 ohms is 1/2 full. A trip to Radio Shack for the closest combination of resistors to make 83.5 ohms gets you one 68 Ohm (Catalog #: 271-1106) + one 15 Ohm (Catalog #: 271-1102) for a total of 83 Ohms at the cost of $2 plus tax. Wire the resistors in series to make a resistor pack and cover it with heat shrink tubing or electrical tape. The 83 Ohms is close enough to the 83.5 Ohm figure that it shouldn't matter. Disconnect the electrical connector shown in your for the tank sender unit. Connect one end of the resistor pack to the yellow/white wire on the body side fuel sender electrical connector and the other end of the resistor pack to ground. Make sure nothing is touching that isn't supposed to and turn the ignition switch to Run. If I am correct, the fuel gauge will read 1/2 full, or very close to it. If it does not, then the odds are that the gauge or anti-slosh unit are bad.

How and why the test works…

Most of the fuel gauge failures give a stuck on full or stuck on empty as a problem symptom. Using a resistor combination that mimics 1/2 tank allows you to decide if the gauge and anti-slosh module are the problem source.

If the gauge reads about 1/2 tank with the resistor combination, that points to the sender as being the culprit.

If the gauge reads full or empty with the resistor pack in place of the sender, then the gauge or anti-slosh module is at fault.

Fuel gauge sender testing and replacement

The next steps require dropping the fuel tank and removal of the fuel level sender. Here are some useful tips...

I have done the tank removal three times, and the main issues are getting the car up on jack stands and getting the gas out of the tank. DO NOT try to do this job without jack stands. Becoming a pancake is not part of the repair process.

Pumping out the old gas:

If the old pump still works, you can use it to pump the tank out.

1.) Separate the pressure line (the one with the Schrader valve on it) using the fuel line tools.

Look in the A/C repair section for the fuel line tools. They look like little plastic top hats. You will need the 1/2" & 5/8" ones. The hat shaped section goes on facing the large part of the coupling. Then you press hard on the brim until it forces the sleeve into the coupling and releases the spring. You may need someone to pull on the line while you press on the coupling.

OR

View: https://www.youtube.com/watch?v=vRTjYAxvaCs

Use a piece of garden hose to run from the pressure line to your bucket or gas can. Make sure it is as leak proof as you can make it. Fire and explosion are not part of the repair process...

2.) Jumper the fuel pump test point to ground.

Turn the ignition switch to the Run position. the fuel pump will pump the tank almost dry unless the battery runs down first.

Some 5 gallon paint pails lined with garbage bags are good to hold the gas. The garbage bags provide a clean liner for the pails and keep the loose trash out of the gas so you can reuse it. If you decide to use a siphon, a piece of 1/2" garden hose stuck down the filler neck will siphon all but a gallon or so of the gas.

Remove the filler neck bolts and put them in a zip bag. Disconnect the supply & return lines by removing the plastic clips from the metal tubing. If you damage the clips, you can get new ones form the auto part store for just a few dollars. I have used tie-wraps, but that is not the best choice. Then you remove the two 9/16" nuts that hold the T bolts to the straps. Put the nuts in the zip bag with the filler bolts. Pull the plastic shield down and away from the tank. Once the tank drops a little bit you can disconnect the wiring for the pump & fuel quantity sender.

The fuel gauge sender assembly comes out by removing a large metal ring that unscrews from the tank. There is a separate mounting/access plate for the fuel pump and fuel gage. You are supposed to use a brass punch to tap on the ring so that you don't make sparks. Look closely at the rubber O ring gasket when you remove the fuel gauge sender.

When you install the metal ring that holds the sender in place, watch out for the gasket O ring. Some RTV may be helpful if the ring is not in excellent condition.

The tank to filler pipe seal is a large rubber grommet. Inspect it for hardening, tears and damage. At $20 from the Ford dealer, it might be a good idea to replace it.

I used a floor jack to help lift the tank back in place. You may find that it is the only time you really can make good use of a helper.

All resistance measurements should be made with the power off.

Note from bstrd86 - 86 and older fuel tank sender units are 73 ohms empty, 8-12 ohms full.

The yellow/white wire will show a voltage that varies with the movement of the float on the sender unit. To test the sender, set your Ohmmeter or DVM on low Ohms. Then disconnect the sender and connect the Ohmmeter or DVM to the yellow/white and black wires from the sender unit. Move the float arm while watching the Ohmmeter or DVM. You should see the reading change from 22 to 145 ohms +/- 10%.

If the Ohmmeter or DVM resistance readings are way off, replace the tank sender unit.

Use extreme caution if you do the next step. Fumes from the gas tank can easily ignite and cause a fire or explosion.

With the sender unit out of the tank and connected to the body wiring harness, turn the ignition switch to the Run position. Move the float arm and the fuel gauge indicator should move. If you are very careful, you can use a pair of safety pins inserted in the connector for the yellow/white and black wires to measure the voltage as you move the float arm. The voltage will change, but I have no specs for what it should be.

Do not short the safety pins together or to ground. If you do, you may damage the anti-slosh module or crate a spark. A spark with the fuel tank open could cause a fire or an explosion.

If the voltage does not change and the tanks sender passed the resistance tests, the anti-slosh module or gauge is bad.

Anti-Slosh module pictures courtesy of Saleen0679

Copied from DrBob

I worked on an 88 Mustang today that had similar symptoms. Short version, I took the “anti slosh module” off of the back of the instrument cluster and replaced the electrolytic capacitor. Fixed it for $1.39 with a part from Radio Shack.

In an attempt to help other folks, here’s the long version.

Remove the “anti slosh module” located on the back of the instrument cluster. There was a single Torx screw holding mine to the cluster.

Find the electrolytic capacitor. It will be the largest, 2 wire component on the board. The capacitor may have a red or blue plastic wrapper on it. Mine was red.

The wrapper should have printing on it. Look for printing that looks something like this:

100uF+25V

The “100uF” tells you this is a 100 micro Farad capacitor. The “+25V” tells you the capacitor is rated for 25 Volts. Yours may be different. You may use a higher voltage part but don't use a lower rated voltage part. If you use a lower voltage part the capacitor might open later on down the road or it could be as bad as catching fire.

If you can’t find the printing you’ll need to remove the part. You have to anyway so nothing wasted. However pay close attention to the way the capacitor is oriented on the board.

One end of the capacitor will be bare metal with a wire sticking out. The other end should have some sort of insulation over it with a wire sticking out. The bare metal end is the negative end while the insulated end is the positive end. Pay attention to which end is connected to which hole on the board.

Get a replacement part. I got mine at Radio Shack, $1.39. Here’s the info:

100µF 35V 20% Axial-Lead Electrolytic Capacitor

Model: 272-1016 | Catalog #: 272-1016

Fuel tank sender unit:

http://www.latemodelrestoration.com/products/Mustang-Gas-And-Fuel-Tank-Sending-Unit

Be sure to get the lock ring and a new seal if you order the tank sender unit.

http://www.latemodelrestoration.com...ng-Fuel-Pump-Sending-Unit-Lock-Ring-And-Seal\

Have oyu actually run the engine codes? Just cuz the CEL isn't on doesn't mean a code is not stored.

Hard start with warm could be a faulty ECT sensor. Should show as a code 21, but you need to run the codes after the engine is up to temp or you will get a false code 21 which always comes up when the engine is cold.

Hard start with warm could be a faulty ECT sensor. Should show as a code 21, but you need to run the codes after the engine is up to temp or you will get a false code 21 which always comes up when the engine is cold.

Similar threads

- Replies

- 25

- Views

- 2K

- Replies

- 26

- Views

- 1K

- Replies

- 25

- Views

- 2K

- Replies

- 56

- Views

- 5K

- Replies

- 6

- Views

- 467