You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Head Swap Build Thread: And other Improvements

- Thread starter Venom351R

- Start date

-

Sponsors (?)

Well after 3 long months the cylinder heads are finally done!!!!!! Ed shipped them to me yesterday. He said he enclosed a "gift" I was hoping it was a free set of roller rockers but I found out later that its an additional bill for $140 lol thanks Ed.

Here are the head specs below.

[FONT="]TFS Custom CNC Ported 234HR High Port Heads[/FONT]

[FONT="]2.055” x 5/16” Super Alloy Intake Valves[/FONT]

[FONT="]1.600” x 5/16” Super Alloy Exhaust Valves[/FONT]

[FONT="]Lunati 73925 LSX Dual Valve Spring Kit[/FONT]

[FONT="]TFS Hardened Guide Paltes for 5/16” Push Rods[/FONT]

[FONT="]ARP Pro-Series 7/16” Rocker Arm Studs[/FONT]

only pics I have so far.

Here are the head specs below.

[FONT="]TFS Custom CNC Ported 234HR High Port Heads[/FONT]

[FONT="]2.055” x 5/16” Super Alloy Intake Valves[/FONT]

[FONT="]1.600” x 5/16” Super Alloy Exhaust Valves[/FONT]

[FONT="]Lunati 73925 LSX Dual Valve Spring Kit[/FONT]

[FONT="]TFS Hardened Guide Paltes for 5/16” Push Rods[/FONT]

[FONT="]ARP Pro-Series 7/16” Rocker Arm Studs[/FONT]

only pics I have so far.

rio95

Member

huh? lol

Well the heads came today. I have set of stock rear springs coming tomorrow so I can get the car back down on 4 wheels again and the powder coated items will be here saturday. Just have to order some head gaskets and then I can start to work on the correct push rod length and the PVC.

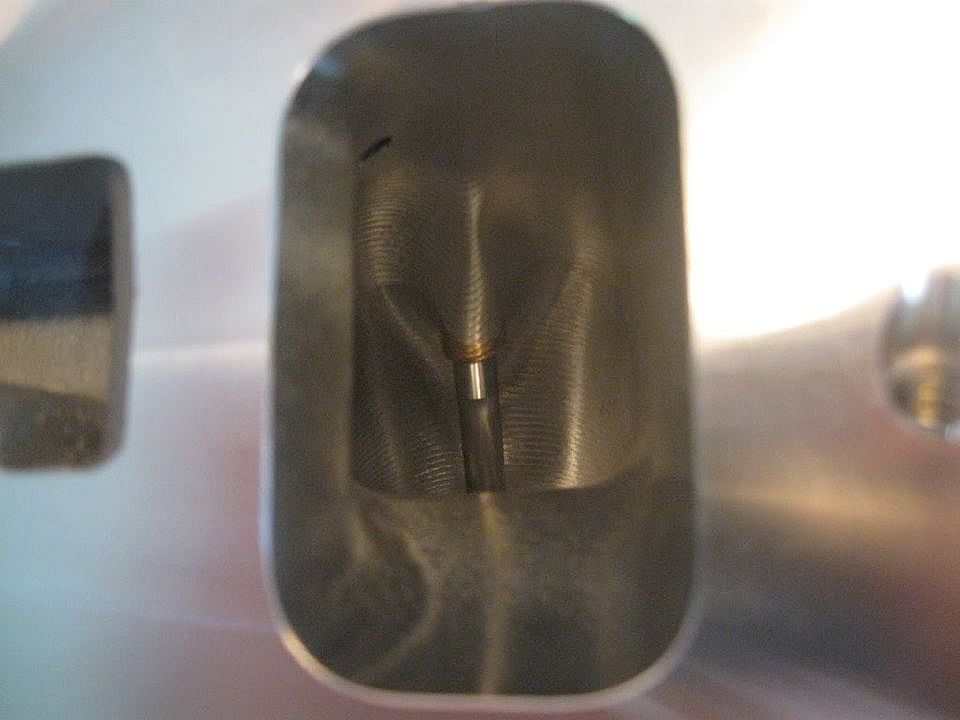

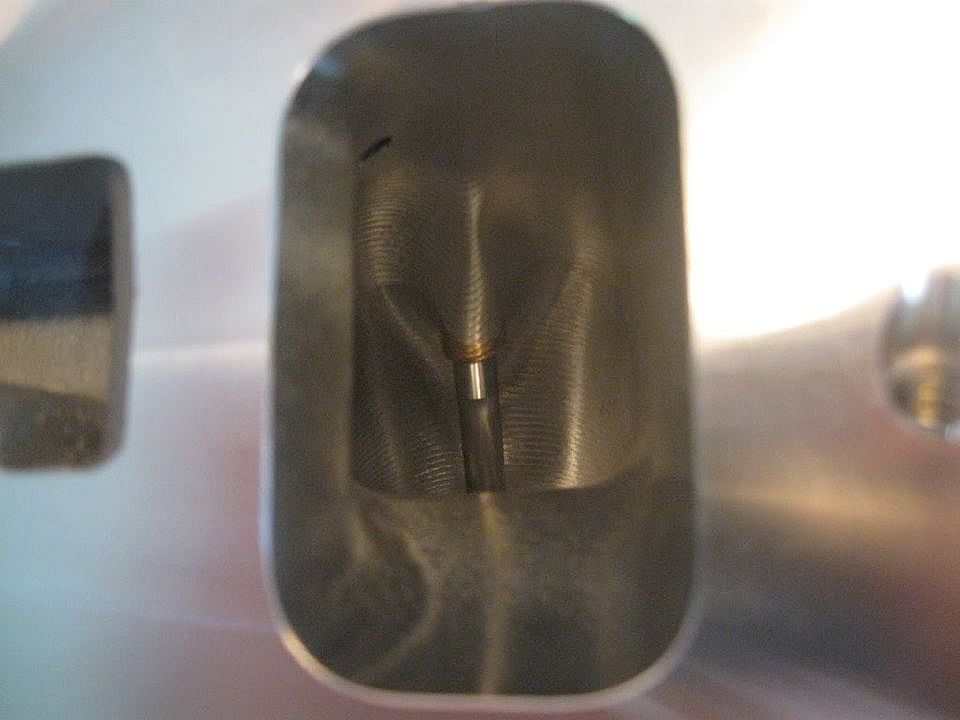

Here are some long awaited pics of the new heads.

As far as some more info on the heads here are the flow numbers.

Lift Intake Exhaust

.100" ..80 .58

.200" 142 115

.300" 196 150

.400" 258 190

.500" 304 215

.550" 320 220

.600" 333 222

.650" 340 230

.700" 334 236

.750" 340 238

The heads also use 5/16" valve stem, not the standard 11/32" stems. These valves are over 20% lighter then the competition. As quoted by Ed. He said this valve train with the correct push rods will spin up the lower 7K range. They are also 64cc Combustion chambers.

Well the heads came today. I have set of stock rear springs coming tomorrow so I can get the car back down on 4 wheels again and the powder coated items will be here saturday. Just have to order some head gaskets and then I can start to work on the correct push rod length and the PVC.

Here are some long awaited pics of the new heads.

As far as some more info on the heads here are the flow numbers.

Lift Intake Exhaust

.100" ..80 .58

.200" 142 115

.300" 196 150

.400" 258 190

.500" 304 215

.550" 320 220

.600" 333 222

.650" 340 230

.700" 334 236

.750" 340 238

The heads also use 5/16" valve stem, not the standard 11/32" stems. These valves are over 20% lighter then the competition. As quoted by Ed. He said this valve train with the correct push rods will spin up the lower 7K range. They are also 64cc Combustion chambers.

Those are some big ports. Put your head in there and look around. Man those are really nice. We just put 10 year old GT40X heads on the 92GT a few days ago. Rog had me looking at the new Vortech V3 self contained kit today so these heads will have to do for now. Our next set may be the ones you have for a big motor. Those are really Sharp, congrats and get them on the car already.

I will as soon as I can. Im waiting on a set of rear springs to get here so I can put the car back down on 4 wheels again and then I can get started on the engine. The springs will be here tomorrow and the rest of the powder coated parts will be here saturday. I can order the head gaskets through summit and get them early in the week and then I can get started on finding the correct push rod length and the PVC. Ive been reading up a lot on how to do both, I have never done either one before so I hope it goes as smooth and as easy as its looked online.

I spent as much on these heads as most would for a supercharger kit, I figured if I'm going to stay NA I might as well put a set of big as nasty heads on it in lieu of a supercharger or turbo.

PS: I really like the build thread you have as well.

I spent as much on these heads as most would for a supercharger kit, I figured if I'm going to stay NA I might as well put a set of big as nasty heads on it in lieu of a supercharger or turbo.

PS: I really like the build thread you have as well.

My god those are some crazy flow numbers. That engine is going to be an animal. That is without a doubt the next set of heads I want.

Kurt

Kurt

It looks like it did some amazing work on them. Is that a 2.08" intake valve, and a 1.64" exhaust?

Kurt

Kurt

I'm pretty sure those are TF 235cc heads which come premachined for 2.08" valves. If he got 2.02" valves to flow that way, that's even more impressive. He might have gone that route because of your current pistons.

Kurt

Kurt

From the start I told him the PVC was my biggest concern so that's why he went with the high ports bc of where it places the valves. When I go to check the PVC I know I only have to bolt the head down near the cylinder I am using which will be the # 1. How much do I have to torque the head for that cylinder?

I wouldn't torque it down much at all, just wrist tight. If the PVC is that close, then I'd start looking into other solutions anyway. I didn't realize those were High Ports, I had assumed they were Twisted Wedges. That's even more amazing. Probably could squeeze another 10cfms out of the Twisted Wedges.

Kurt

Kurt

blksn955.o

Founding Member

When you get your alt. bracket sand the area that comes into contact with the heads (Mine is a small raised circle were each bolt hole is that goes into the heads).

Also sand the area that touches the alt.

When I had my brackets coated I had to sand them down as the alt grounds through the bracket/block. I was getting no power from the alt. discovered this the hard way and might save you some headache.

Takes 10-15min to do by hand with them off...PITA with them on the car still.

Also sand the area that touches the alt.

When I had my brackets coated I had to sand them down as the alt grounds through the bracket/block. I was getting no power from the alt. discovered this the hard way and might save you some headache.

Takes 10-15min to do by hand with them off...PITA with them on the car still.

blksn955.o

Founding Member

When your ready just contact ED he will set u right up. I have someone sending me a solid lifter so I can check the PVC

If you end up still needing a lifter I have a factory one that was made solid.

Thanks Kurt and I'll make sure to do that blknn, thanks.

Im really excited to get all this together and running now. I know on paper it should be a monster but the dyno and track will be the real test. I can pick up some modeling clay on monday and get the PVC checked then once I have my lifter I can find the correct push rod to use. So hopefully this week I can get all that done.

Kurt I just checked the invoice card on the heads and they have 2.05 Intake valves and 1.60 exhaust valves, both 5/16

Im really excited to get all this together and running now. I know on paper it should be a monster but the dyno and track will be the real test. I can pick up some modeling clay on monday and get the PVC checked then once I have my lifter I can find the correct push rod to use. So hopefully this week I can get all that done.

Kurt I just checked the invoice card on the heads and they have 2.05 Intake valves and 1.60 exhaust valves, both 5/16

Cool. I would be surprised to see a Trick Flow Head that big with a 2.02 valve. Stunning flow numbers for a 2.05" valve.

Kurt

Kurt

blksn955.o

Founding Member

I am interested on how those heads work out on a 351 (IIRC your setup is not a stroker). An old buddy of mine had a 347 with some TFS heads that flowed in the 320 range and it was a friggan monster....

For example..."on a closed course"

We pulled next to an 11.2 Nova buddy gave the nova the bump.

Nova hooked and was gone...

Buddies car spun to 7k in 1st...then shifted to 2nd and spun to 5,500-6k.

At said rpm in 2nd hooked and then by the time he hit 5k in 3rd he had not only caught said 11.2 nova but was pulling on it and the nova drivers jaw dropped. Fairly impressive to catch an 11.2 car in 1k-ish rpm in 2nd and 5k rpm of 3rd

This was in a carb'd 84 hatch with a C4 and a peg leg 7.5 that had 4.11's (no kidding).

For example..."on a closed course"

We pulled next to an 11.2 Nova buddy gave the nova the bump.

Nova hooked and was gone...

Buddies car spun to 7k in 1st...then shifted to 2nd and spun to 5,500-6k.

At said rpm in 2nd hooked and then by the time he hit 5k in 3rd he had not only caught said 11.2 nova but was pulling on it and the nova drivers jaw dropped. Fairly impressive to catch an 11.2 car in 1k-ish rpm in 2nd and 5k rpm of 3rd

This was in a carb'd 84 hatch with a C4 and a peg leg 7.5 that had 4.11's (no kidding).

Similar threads

Progress Thread

H/C Swap Problems/Ideas

- Replies

- 3

- Views

- 370

- Replies

- 65

- Views

- 4K

- Replies

- 13

- Views

- 1K

- Replies

- 4

- Views

- 1K

- Replies

- 2

- Views

- 1K