If you get a code 67, you will not be able to pull engine running codes. You need to have the Neutral Safety Switch (pigtail cable on the shifter) connected to the transmission wiring harness and working properly.

Code 21 or 116 – ECT sensor out of range. Broken or damaged wiring, bad ECT sensor.

Note that that if the outside air temp is below 50 degrees F that the test for the

ECT can be in error. This code may go away as the engine warms up, so don't dump the codes

on a cold engine

The ECT sensor has absolutely nothing to do with the temperature gauge. They are

different animals. The ECT sensor is normally located it the RH front of the engine in

the water feed tubes for the heater.

The ACT & ECT have the same thermistor, so the table values are the same

ACT & ECT test data:

Use Pin 46 on the computer for ground for both ECT & ACT to get most accurate

readings.

Pin 7 on the computer - ECT signal in. at 176 degrees F it should be .80 volts

Pin 25 on the computer - ACT signal in. at 50 degrees F it should be 3.5 volts. It is

a good number if the ACT is mounted in the inlet airbox. If it is mounted in the lower

intake manifold, the voltage readings will be lower because of the heat transfer.

Voltages may be measured across the ECT/ACT by probing the connector from

the rear. A pair of safety pins may be helpful in doing this. Use care in doing it

so that you don't damage the wiring or connector.

Here's the table :

50 degrees F = 3.52 v

68 degrees F = 3.02 v

86 degrees F = 2.62 v

104 degrees F = 2.16 v

122 degrees F = 1.72 v

140 degrees F = 1.35 v

158 degrees F = 1.04 v

176 degrees F = .80 v

194 degrees F = .61

212 degrees F = .47 v

230 degrees F = .36 v

248 degrees F = .28 v

Ohms measures at the computer with the computer disconnected, or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

212 degrees F = 2.07 K ohms

230 degrees F = 1.55 K ohms

248 degrees F = 1.18 k ohms

Diagram courtesy of Tmoss & Stang&2birds

Code 22 or 126 MAP (vacuum) or BARO signal out of range. The MAP or BARO sensor is pretty much the same sensor for both Mass Air & Speed Density cars. The main difference is where it is connected. Mass Air cars vent it to the atmosphere, while Speed Density cars connect it to the intake manifold vacuum. Its purpose is to help set a baseline for the air/fuel mixture by sensing changes in barometric pressure. The MAP or BAP sensor puts out a 5 volt square wave that changes frequency with variations in atmospheric pressure. The base is 154 HZ at 29.92" of mercury - dry sunny day at sea level, about 68-72 degrees. You need an oscilloscope or frequency meter to measure it. There a very few DVM with a price tag under $40 that will measure frequency, but there are some out there.

The MAP/BARO sensor is mounted on the firewall behind the upper manifold on 86-93 Mustangs.

Baro or MAP test using frequency meter - run the test key on engine off. The noise from the ignition system will likely upset the frequency meter. I used a 10 x oscilloscope probe connected from the frequency meter to the MAP/BAP to reduce the jitter in the meter's readout.

If it is defective, your air/fuel ratio will be off and the car’s performance & emissions will suffer

Some basic checks you can make to be sure that the sensor is getting power & ground:

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter.

Check the resistance between the black/white wire on the MAP/BARO sensor and then the black/white wire on the EGR and the same wire on the TPS. It should be less than 1 ohm. Next check the resistance between the black/white wire and the negative battery cable. It should be less than 1.5 ohm.

The following power on check requires you to turn the ignition switch to the Run position.

Use a DVM to check for 5 volts on the orange/white wire. If it is missing, look for +5 volts at the orange/white wire on the TPS or EGR sensors. Use the black/white wire for the ground for the DVM.

Code 24 - Intake Air Temperature (ACT) sensor out of range.

Bad sensor, bad wiring. The ACT for Mustangs built before 95 is in the

#5 intake runner. It measures the air temperature in the intake to help

computer the proper air/fuel ratio.

Note that that if the outside air temp is below 50 degrees F that the test for the ACT can be in error.

ACT & ECT test data:

The ACT & ECT have the same thermistor, so the table values are the same

Pin 7 on the computer - ECT signal in. at 176 degrees F it should be .80 volts

Pin 25 on the computer - ACT signal in. at 50 degrees F it should be 3.5 volts.

It is a good number if the ACT is mounted in the inlet airbox. If it is mounted in

the lower intake manifold, the voltage readings will be lower because of the heat transfer.

Here's the table :

50 degrees F = 3.52 v

68 degrees F = 3.02 v

86 degrees F = 2.62 v

104 degrees F = 2.16 v

122 degrees F = 1.72 v

140 degrees F = 1.35 v

158 degrees F = 1.04 v

176 degrees F = .80 v

194 degrees F = .61

212 degrees F = .47 v

230 degrees F = .36 v

248 degrees F = .28 v

Ohms measures at the computer with the computer disconnected,

or at the sensor with the sensor disconnected.

50 degrees F = 58.75 K ohms

68 degrees F = 37.30 K ohms

86 degrees F = 27.27 K ohms

104 degrees F = 16.15 K ohms

122 degrees F = 10.97 K ohms

140 degrees F = 7.60 K ohms

158 degrees F = 5.37 K ohms

176 degrees F = 3.84 K ohms

194 degrees F = 2.80 K ohms

212 degrees F = 2.07 K ohms

230 degrees F = 1.55 K ohms

248 degrees F = 1.18 k ohms

Code 34 Or 334 - EGR voltage above closed limit - Failed sensor, carbon between EGR pintle valve and seat holding the valve off its seat or vacuum control problems. Remove the EGR valve and clean it with carbon remover. Prior to re-installing see if you can blow air through the flange side of the EGR by mouth. If it leaks, there is carbon stuck on the pintle valve seat, replace the EGR valve ($85-$95).

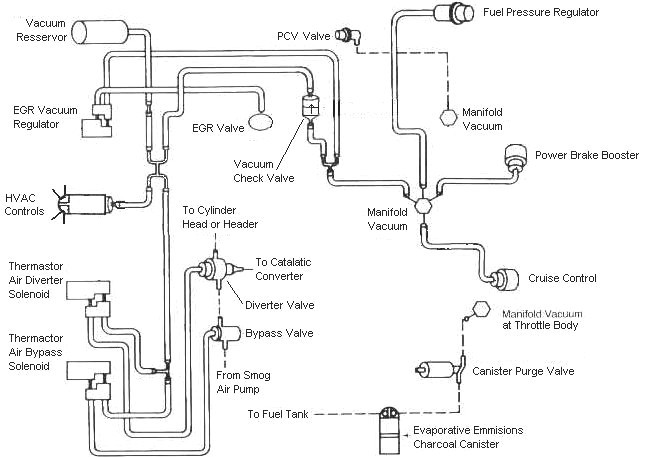

Vacuum control problems:

If someone has misrouted the EGR vacuum plumbing or the EVR (Electronic Vacuum Regulator) has failed, you can get this code.

Diagram courtesy of Tmoss & Stang&2birds

EGR test procedure courtesy of cjones

to check the EGR valve:

bring the engine to normal temp.

connect a vacuum pump to the EGR Valve or

see the EGR test jig drawing below. Connnect the test jig or to directly to manifold vacuum.

Do not connect the EGR test jig to the EVR (Electronic Vacuum Regulator).

apply 5in vacuum to the valve.

Using the test jig, use your finger to vary the vacuum

if engine stumbled or died then EGR Valve and passage(there is a passageway through the heads and intake) are good.

if engine did NOT stumble or die then either the EGR Valve is bad and/or the passage is blocked.

if engine stumbled,

connect EGR test jig to the hose coming off of the EGR Valve.

Use your finger to cap the open port on the vacuum tee.

snap throttle to 2500 RPM (remember snap the throttle don't hold it there).

did the vacuum gauge show about 2-5 in vacuum?

if not the EVR has failed

EGR test jig

If the blow by test passes, and you have replaced the sensor, then you have electrical ground problems. Check the resistance between the black/white wire on the MAP/BARO sensor and then the black/white wire on the EGR and the same wire on the TPS. It should be less than 1.5 ohm. Next check the resistance between the black/white wire and the negative battery post. It should be less than 1.5 ohm.

Note that all resistance tests must be done with power off. Measuring resistance with a circuit powered on will give false readings and possibly damage the meter.

Let’s put on our Inspector Gadget propeller head beanies and think about how this works:

The EGR sensor is a variable resistor with ground on one leg and Vref (5 volts) on the other. Its’ resistance ranges from 4000 to 5500 Ohms measured between Vref & ground, depending on the sensor. The center connection of the variable resistor is the slider that moves in response to the amount of vacuum applied. The slider has some minimum value of resistance greater than 100 ohms so that the computer always sees a voltage present at its’ input. If the value was 0 ohms, there would be no voltage output. Then the computer would not be able to distinguish between a properly functioning sensor and one that had a broken wire or bad connection. The EGR I have in hand reads 700 Ohms between the slider (EPV) and ground (SIG RTN) at rest with no vacuum applied. The EGR valve or sensor may cause the voltage to be above closed limits due to the manufacturing tolerances that cause the EGR sensor to rest at a higher position than it should.

The following sensors are connected to the white 10 pin connector (salt & pepper engine harness connectors)

This will affect idle quality by diluting the intake air charge

Code 67 - clutch not depressed (5 speed) or car not in neutral or park (auto) or A/C in On position when codes where dumped. Possible neutral safety switch or wiring problem. This code may prevent you from running the Key On Engine On tests. You can generally ignore this code, since it has no effect on engine performance.

The computer wants to make sure the A/C is off due to the added load on the engine for the engine running tests. It also checks to see that the transmission is in Neutral or the clutch depressed (T5, T56, Tremec 3550 & TKO). This prevents the diagnostics from being run when the car is driven. Key On Engine Running test mode takes the throttle control away from the driver for several tests. This could prove hazardous if the computer was jumpered into test mode and then driven.

The NSS code 67 can be bypassed for testing. You will need to temporarily ground computer pin 30 to the chassis. Computer pin 30 uses a Lt blue/yellow wire. Remove the passenger side kick panel and then remove the plastic cover from the computer wiring connector. Use a safety pin to probe the connector from the rear and jumper the safety pin to the ground near the computer.

Code 85 - CANP solenoid - The Carbon Canister solenoid is inoperative or missing. Check vacuum lines for leaks and cracks. Check electrical wiring for loose connections, damaged wiring and insulation. Check solenoid valve operation by grounding the gray/yellow wire to the solenoid and blowing through it.

The computer provides the ground for the solenoid. The red wire to the solenoid is always energized any time the ignition switch is in the run position.

Charcoal canister plumbing - one 3/8" tube from the bottom of the upper manifold to the rubber hose. Rubber hose connects to one side of the canister solenoid valve. Other side of the solenoid valve connects to one side of the canister. The other side of the canister connects to a rubber hose that connects to a line that goes all the way back to the gas tank. There is an electrical connector coming from the passenger side injector harness near #1 injector that plugs into the canister solenoid valve. It's purpose is to vent the gas tank. The solenoid valve opens at cruse to provide some extra fuel. The canister is normally mounted on the passenger side frame rail near the smog pump pulley.

It does not weigh but a pound or so and helps richen up the cruse mixture. It draws no HP & keeps the car from smelling like gasoline in a closed garage. So with all these good things and no bad ones, why not hook it up & use it?

The purge valve solenoid connector is a dangling wire that is near the ECT sensor and oil filler on the passenger side rocker cover. The actual solenoid valve is down next to the carbon canister. There is about 12"-16" of wire that runs parallel to the canister vent hose that comes off the bottom side of the upper intake manifold. That hose connects one port of the solenoid valve; the other port connects to the carbon canister.

Purge valve solenoid:

The carbon canister is normally mounted on the passenger side frame rail near the smog pump pulley.

Carbon Canister:

Code 95 Key On, Engine not Running - the following test path is for 86-90 model Mustangs.

The 95 code is because at one time or another, the fuel pump relay hiccupped and didn't provide power the pump when the computer told it to run. Sometimes this is a one time thing, other times it is a no run or runs poorly condition.

Suspect items are bad fuel pump relay, corrosion in the fuel pump relay socket, inertia switch, wiring damage , corroded connector contacts.

Using the diagram, check the red/black wire from the fuel pump relay: you should see 12 volts or so. If not, check the inertia switch: on a hatch it is on the driver’s side by the taillight. Look for a black rubber plug that pops out: if you don't find it, then loosen up the plastic trim. Check for voltage on both sides of the switch. If there is voltage on both sides, then check the Pink/black wire on the fuel pump relay: it is the power feed to the fuel pump. No voltage there, check the Orange/Lt blue wire, it is the power feed to the fuel pump relay & has a fuse link in it. If there is good voltage there & at the Pink/black wire, swap the relay.

Some Mass Air conversions neglect to run the extra fuel pump wire, and they always have a 95 code. See

Mustang Mass Air Conversion | StangNet for more information on the Mass Air wiring conversion.

Probable cause:

You have some wiring problems, so you will get to do a resistance test from the affected sensors to the 10 pin connectors and then from the 10 pin connectors to the computer. Use the computer wiring diagram as your guide for testing the wires.

Basic sensor wiring test:

Tools needed:

DMM (Digital MUlti Meter) with good batteries. Know the difference between voltage (volts) and resistance (ohms) and how to measure them with your DMM. Make sure you know how to read voltages and resistances with you meter. Some DMM’s auto range and others require you to select the range. Be sure you understand the range selection process if your DMM does not auto range. Do not touch the probe tips while making resistance measurements. If you do, your measurements will be very wrong.

Two or three big safety pins. You may need them to probe the electrical connector plugs from the rear. Keep in mind that it may require some effort to make good connections to use your DMM. Flaky or intermittent connections can lead you down the wrong path.

#2 Philips screwdriver

¼” flat blade screwdriver.

5/16” socket

¼ drive ratchet

3” long 1/4 “ extension.

3/8” ratchet

10 MM deep socket or 10 mm socket & 3” extension.

Disconnect the battery negative cable at the battery. Remove the passenger side kick panel and then loosen the 10 MM hex bolt that secures the computer wiring harness connector to the computer. Pull the computer wiring connector down and away from the computer.

Disconnect the connector from the sensor under test. Set the DMM to ohms and measure the resistance from the wire on the sensor connector to the same wire on the computer wiring connector. You should see less than 1.5 ohms. Next ground one of the DMM leads to the engine block. The other DMM lead goes to the sensor wire you wish to test. You should see more than 100K ohms or an infinite open circuit.

Computer wiring harness connecter as viewed from the

pin side.

See the computer wiring diagram in this post for more information on the computer wiring.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds

(website host) for help on 88-95 wiring

Mustang FAQ - Wiring & Engine Info

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg