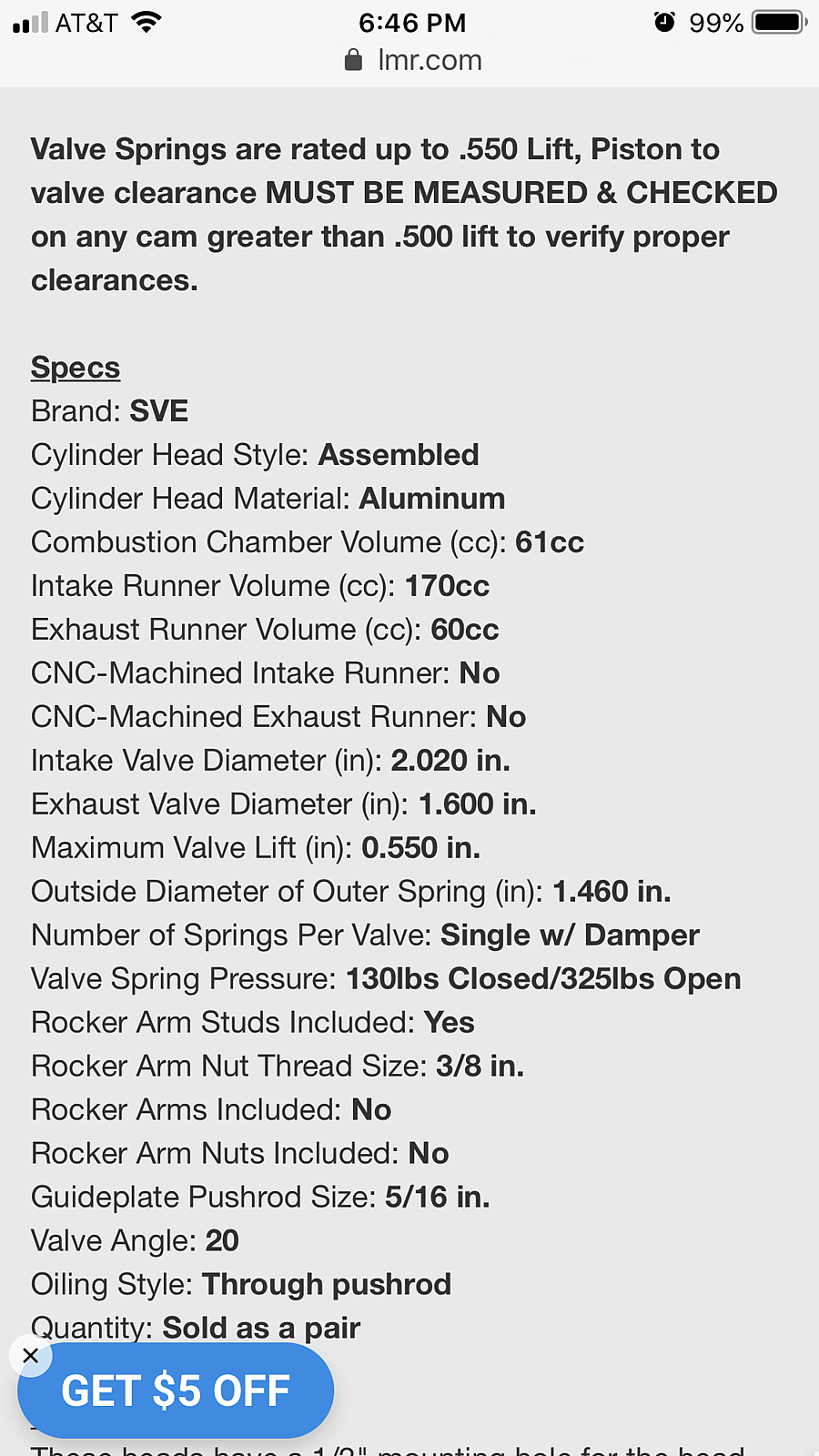

I cleaned the pistons with acetone if I remember right. It’s the same chemical as the spray foam stuff. Yes I installed, the tfs stage 1 cam. Read the fine print on the heads and you’ll see they easily clear a cam under .500 lift.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My ‘89 GT build

- Thread starter sigsterrr

- Start date

-

Sponsors (?)

Finally able to do more work, but only for a short time. First, I fit the Cobra booster before doing any body work. For those curious, I grinded the welds (I welded up all the bolt holes when I was welding up the rest of the engine bay) on the panel at the top of the firewall, put a skim coat of bodyfiller and then sanded it smooth. First using a 3m filing board with 80 grit, then hand sanding the hard to reach spots (with 80 grit). I scuffed the entire engine bay with Carborundum red scuff pads (my favorite) before primering it. If it wasn’t raining I might have shot it with some basecoat/clearcoat today also. Just a couple spots to fill/sand and it will finally be ready.

I will. I called Edelbrock this morning and they told me that I would have to add relief when using the 60399 5.0 Performer heads with 2.02" intakes. I see you have the factory E7ZA- 0 -CA forged pistons. I am going to see if there is an installation note on the SVE heads at LMR. I won't know until I tear the engine apart and check. Your heads look like a copy of those that I have.

I will. I called Edelbrock this morning and they told me that I would have to add relief when using the 60399 5.0 Performer heads with 2.02" intakes. I see you have the factory E7ZA- 0 -CA forged pistons. I am going to see if there is an installation note on the SVE heads at LMR. I won't know until I tear the engine apart and check. Your heads look like a copy of those that I have.

Not all heads are the same. Some angle the valves differently specifically to allow a larger lift without flycutting.

Man you move fast, I live in the Plant city area and work in Tampa... I have all kinds of parts sitting either on a shelf or in a bin.

OneSick99GT

Active Member

I actually may have a fender liner in the shed, I have no use for the cylinder head but your welcome to PM me and we can set something up.

Doesn’t look like I did much today, but I spent about 8 hours on it today. Painted the rest of the engine bay, painted ac accumulator bracket, radiator brackets, distributor, cobra brake booster. Installed brake booster and new master cylinder (they are just in place and not bolted in yet though). Installed ac accumulator and bracket, distributor, pass side valve cover (swapped cork for felpro) and a few other hits on the engine. ARP flywheel bolts get here Monday. Hopefully by Friday I will have the engine and transmission in the car.

mikestang63

SN Certified Technician

save up for a good set of afr or TW heads

I’m quite happy with the sve heads.

mikestang63

SN Certified Technician

I’m quite happy with the sve heads.

glad to hear it.

They are no where near the quality or flow the same though.

Standard valve angle heads this is correct . Those SVE heads are basically knock of Twisted wedge heads which work fine in this instance . I used tw heads with the same cam about 4-5 years ago and it worked fineI will. I called Edelbrock this morning and they told me that I would have to add relief when using the 60399 5.0 Performer heads with 2.02" intakes. I see you have the factory E7ZA- 0 -CA forged pistons. I am going to see if there is an installation note on the SVE heads at LMR. I won't know until I tear the engine apart and check. Your heads look like a copy of those that I have.

Anti_Hero0932

Well-Known Member

I think i had a set of the SVE heads on an old GT i had they were awesome for what i was doing with the car.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 2

- Views

- 1K

- Replies

- 0

- Views

- 4K

- Replies

- 33

- Views

- 8K