Install a mechanical gauge. The electric gauges have a potential problems because of the the number of electrical connections it the path to the gauge on the instrument panel. If you are interested, reply yo this post and I will give a list of locations that can have connection problems.

Try the gage sender – it’s a good place to start.

I saw some similar type problems – mine never went to zero, but it ran low at idle and wandered all over the place at cruse RPM. Still does, even with new sender, rebuilt engine and a HD/high volume oil pump. It’s an electrical problem I’ll fix – some day - maybe.

If you are the handy type, you can install a direct reading gauge under the hood as a troubleshooting aid. A cheap 0-100 psi gage, a ¼” pipe T (enables you to continue to use the electrical gage sender), some tubing and fittings will be all you need. If nothing else, it will relieve some of your worries, and it’s neat tool to have after doing any heavy internal engine work.

Mechanical oil pressure gauge installation.

1.) Remove old pressure sender. It is located down by the oil filter and has 1 wire on a push on screw connector.

2.) Install ¼” pipe tee fitting with a short ¼” nipple on the place where you removed the oil pressure sender.

3.) Install the original oil pressure sender back in one of the tee ports.

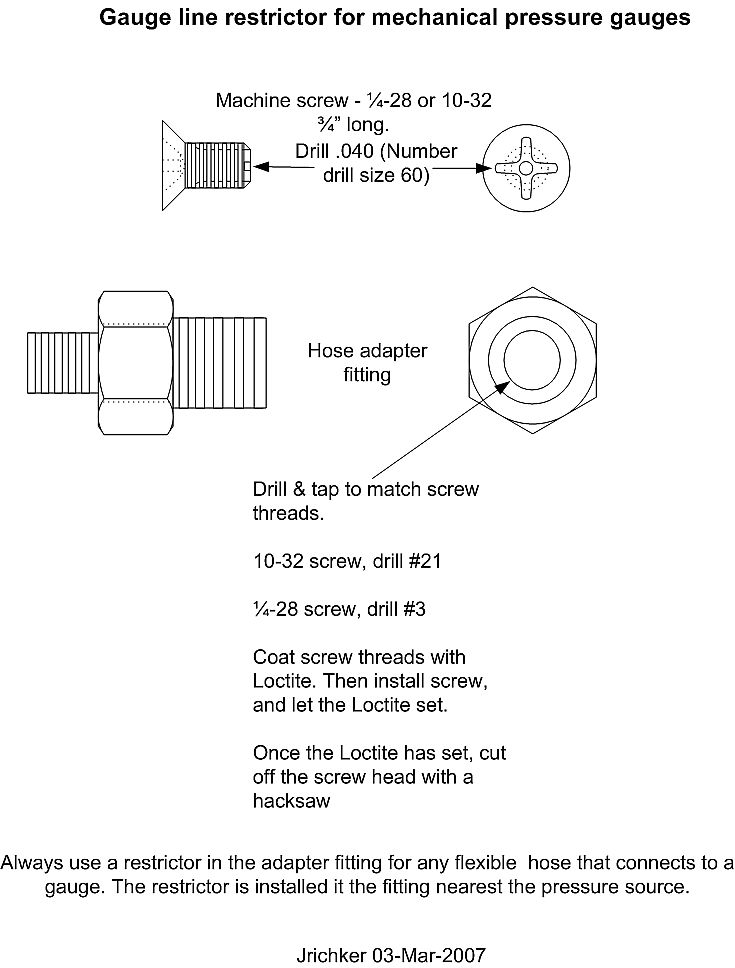

4.) Install the gauge line restrictor in the remaining port of the tee.

5.) Connect the flex tubing or hydraulic hose to the gauge restrictor. Be sure to route the tubing or hose away from the exhaust manifolds. Be sure to either use hydraulic hose or oil and heat resistant flex tubing for the pressure line. Do not use copper tubing for the connection to the gauge restrictor or engine. Over a period of time, the vibration will work harden the tubing and cause it to crack and fail.

6.) If the gauge is going to mount under the hood, connect it to the end of the hose or flex tubing. Use some Tie-wraps to secure the gauge and its plumbing to the wiring harness on the driver’s side inner fender.

7.) If the gauge is going to mount in the passenger compartment you get to find a place to run the tubing through the firewall. I suggest that you pick your spot from the inside since that is the area with the most difficult access. Do not run the tubing through the exact same hole as the steering shaft. It will tangle up with the steering shaft and cause major problems.

8.) Install the gauge inside the car in the location of your choosing. Connect the pressure line to the gauge and secure it out of the way of moving parts with Tie-wraps.

9.) Be sure to ground the gauge lighting wire to clean, shiny bare metal. Connect the other wire from the gauge lighting to a light blue/red wire on the radio wiring harness. There are 2 connectors in the radio wiring harness, but only one of them has the light blue/red wire you need for gauge illumination. Solder the gauge lighting wire to the light blue/red wire on the radio harness and cover the soldered joint with heat shrink.

How to solder like a pro - [

View: http://youtu.be/uaYdCRjDr4A

a must view for any automotive wiring job.

Be sure to use a gauge restrictor fitting in the pressure line going to the gauge. The restrictor will prevent all of the engine's oil supply from ending up on the pavement before you can stop it if the gauge line fails. I had a gauge line rupture, and the restrictor fitting saved my engine from serious damage.