Over the last few months I have had to take the tailshaft housing off of my T-5 transmission 3 times. Each time I have removed the housing and reinstalled it, by myself, and with the transmission still in the car. I was asked to put together a short how to on this subject to help others out in similar situations. A few things to note before I get started. I have a lift, so getting under the car to work on it is easier for me than others working off of jack stands. This job is still very doable without the aid of a lift. I am not a mechanic. Take this advice for just that. The method I'm going to describe here uses materials and tools that might not be readily available to others. I believe it will illustrate the basic concept of how I do this to a degree that others, with a little creativity of their own, will be able to do this job in other ways.

I'm going to start this 'How-To" at the point that everything is ready to go back on the car. I'm going to assume if you want to attempt this you have the know how to take the tailshaft housing off of the transmission.

OK. The tricky part of putting the housing back on is getting the shifter shuttle back on the transmission shifter rod without someone else there to help. I get around this by making a strap using plastic banding that holds the detent ball in while I install the housing.

Here is the shifter shuttle.

In that picture you can see the "bump" on the bottom of the shuttle that rides in the gates, the bottom of the cup that the shifter rides in, the hole that the retainer roll pin goes into and the hole that the detent spring and detent go into.

These are the materials and tools that I use to make the retainer strap.

The idea is to wrap the plastic banding around the shuttle, going across the detent hole, then while not letting the strap move, you remove the shuttle and crimp the strap in place. I think it makes more since in the pictures.

I always make a couple extra with one being a little tighter and one a little looser. The tighter you can hold the detent in the easier it will be to install it along with the housing. The banding and crimping tool are things that I know everyone does not have access to. Now that you understand what needs to happen though I'm sure others can figure out a similar setup using different materials to get the job done. If you need to do this job and do not have a way of making something like I have illustrated just hit me up. I can make one for you.

Now on to the install.

The next trick is to get the detent spring and ball into the shuttle and the band around it all. The way I do it is I place the ball on the edge of a hard surface then hold the spring on it and set the shuttle down over it all. This will push the spring and ball up into the shuttle. You can then put the strap in front of the shuttle and push it into the strap. Be careful doing this and make sure that the strap has captured the detent before you rotate or pick up on the shuttle. If the detent is not captured properly the spring and ball can shoot off never to be seen again.

As you can see in the last pic the detent is being held in there pretty good.

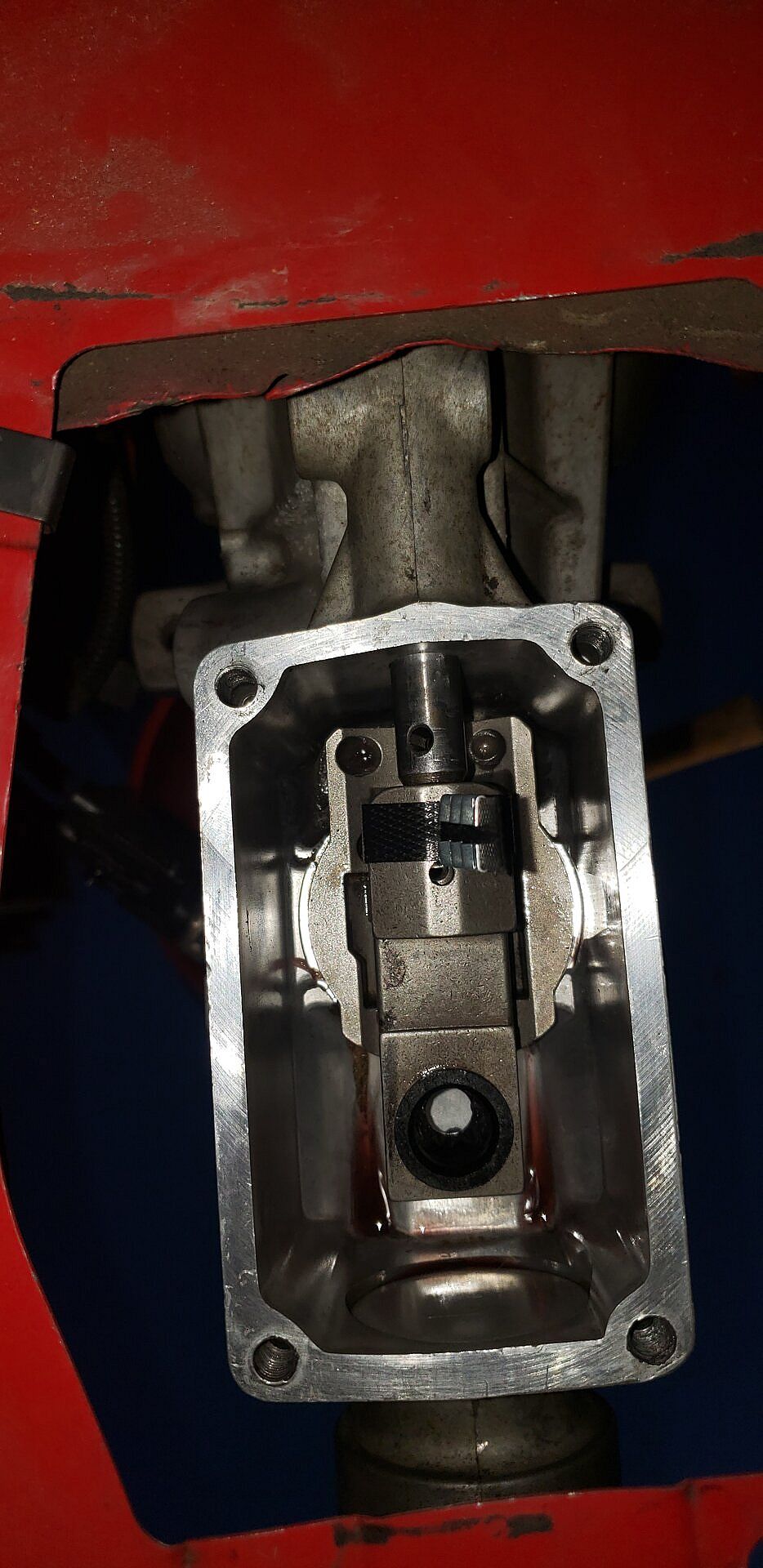

Next get the mating surfaces of the housing and transmission cleaned and prepped. I use an anaerobic gasket maker for the housing. I like it because it remains pliable as long as it is exposed to air. Here is a pic of my housing all ready to be installed.

Next place the shuttle into the housing and slide the housing onto the output shaft and shifter rod.

I'm going to start this 'How-To" at the point that everything is ready to go back on the car. I'm going to assume if you want to attempt this you have the know how to take the tailshaft housing off of the transmission.

OK. The tricky part of putting the housing back on is getting the shifter shuttle back on the transmission shifter rod without someone else there to help. I get around this by making a strap using plastic banding that holds the detent ball in while I install the housing.

Here is the shifter shuttle.

In that picture you can see the "bump" on the bottom of the shuttle that rides in the gates, the bottom of the cup that the shifter rides in, the hole that the retainer roll pin goes into and the hole that the detent spring and detent go into.

These are the materials and tools that I use to make the retainer strap.

The idea is to wrap the plastic banding around the shuttle, going across the detent hole, then while not letting the strap move, you remove the shuttle and crimp the strap in place. I think it makes more since in the pictures.

I always make a couple extra with one being a little tighter and one a little looser. The tighter you can hold the detent in the easier it will be to install it along with the housing. The banding and crimping tool are things that I know everyone does not have access to. Now that you understand what needs to happen though I'm sure others can figure out a similar setup using different materials to get the job done. If you need to do this job and do not have a way of making something like I have illustrated just hit me up. I can make one for you.

Now on to the install.

The next trick is to get the detent spring and ball into the shuttle and the band around it all. The way I do it is I place the ball on the edge of a hard surface then hold the spring on it and set the shuttle down over it all. This will push the spring and ball up into the shuttle. You can then put the strap in front of the shuttle and push it into the strap. Be careful doing this and make sure that the strap has captured the detent before you rotate or pick up on the shuttle. If the detent is not captured properly the spring and ball can shoot off never to be seen again.

As you can see in the last pic the detent is being held in there pretty good.

Next get the mating surfaces of the housing and transmission cleaned and prepped. I use an anaerobic gasket maker for the housing. I like it because it remains pliable as long as it is exposed to air. Here is a pic of my housing all ready to be installed.

Next place the shuttle into the housing and slide the housing onto the output shaft and shifter rod.