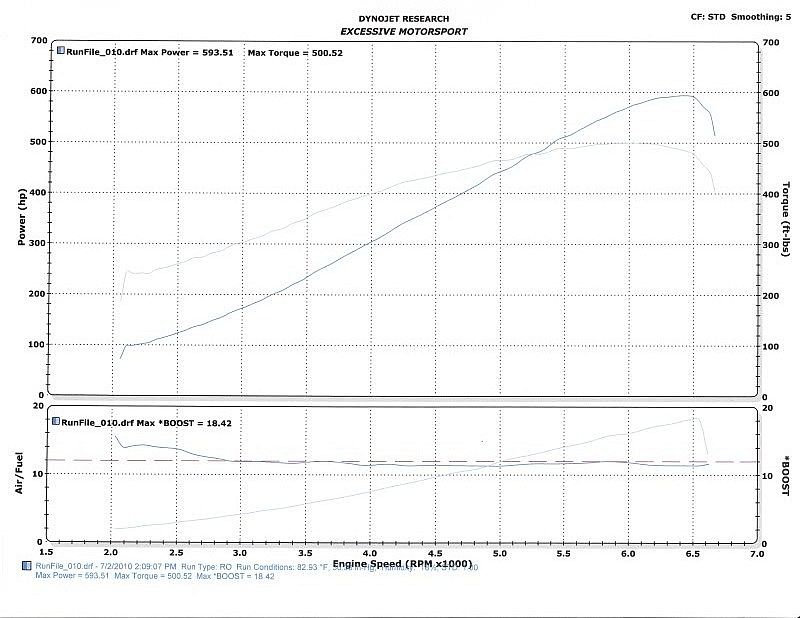

I just finished up my new build, with an 04 Cobra Shortblock, TFS 44cc 2v heads, T-trim, 10% OD dampener and RR intake. It made 598 rwhp on the dyno at 19 psi/6500 rpms.

Then the engine started making funny clacking noises. We thought it was a rod knock at first, but then it mysteriously went away. To this day (a month later), the noise hasn't come back and the car has been run every day. We thought the noise was just a sticking valve or lifter which eventually "un-stuck" itself. The oil was clean, with no metals. We re-dynoed the car and this time it made 550-something rwhp on a very hot/humid day. A 40 hp loss sounds like a lot but its only 6.6% of 598 hp

Anyway, I took it to the track yesterday and made 4-5 passes. I was trapping 94-95 in the 1/8th and 114-115 in the 1/4. Obviously I am not making 598 or even 550 rwhp. 114 mph is what I used to trap when I was making 360 rwhp.

Today, I pulled the plugs and did a compression check. Compression was good, 160-170 psi in all 8 cylinders. But I did notice that two of the plugs on the passenger side (two plugs closest to the front of the car), had a much narrower gap (0.013 and 0.018) than the other plugs (0.025).

My questions:

(1) Could the narrower gap in the two plugs have caused such a tremendous power loss?

(2) Could the sticking lifter problem have caused the piston to hit spark plug and bend in the electrode?

(3) Spark plug recommendation for TFS 2v heads + 04 Cobra Shortblock?

Then the engine started making funny clacking noises. We thought it was a rod knock at first, but then it mysteriously went away. To this day (a month later), the noise hasn't come back and the car has been run every day. We thought the noise was just a sticking valve or lifter which eventually "un-stuck" itself. The oil was clean, with no metals. We re-dynoed the car and this time it made 550-something rwhp on a very hot/humid day. A 40 hp loss sounds like a lot but its only 6.6% of 598 hp

Anyway, I took it to the track yesterday and made 4-5 passes. I was trapping 94-95 in the 1/8th and 114-115 in the 1/4. Obviously I am not making 598 or even 550 rwhp. 114 mph is what I used to trap when I was making 360 rwhp.

Today, I pulled the plugs and did a compression check. Compression was good, 160-170 psi in all 8 cylinders. But I did notice that two of the plugs on the passenger side (two plugs closest to the front of the car), had a much narrower gap (0.013 and 0.018) than the other plugs (0.025).

My questions:

(1) Could the narrower gap in the two plugs have caused such a tremendous power loss?

(2) Could the sticking lifter problem have caused the piston to hit spark plug and bend in the electrode?

(3) Spark plug recommendation for TFS 2v heads + 04 Cobra Shortblock?