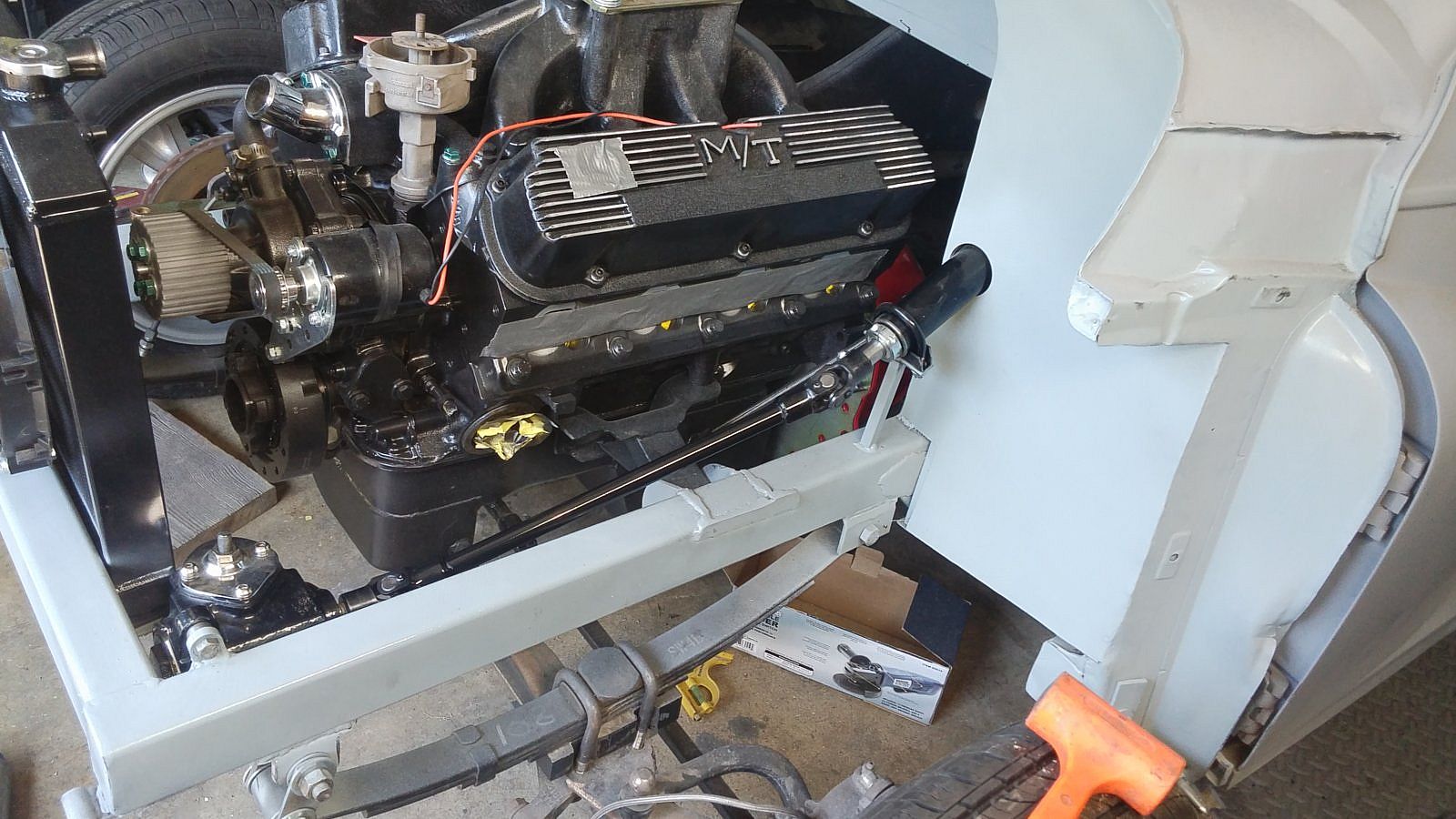

This is my 1958 Morris Minor that I bought 3 years ago . It went from a stock Morris to the stage it is in right now.

I found this car setting in South Carolina in a car port. It had been setting for 10 years waiting to be hot rodded.

Unfortunately the previous owner has cancer and couldn't do the car so I bought the car and took it home to my shop in Florida.

Here is the day I got it home and the day I took it to the first Southeast Gasser race in Knoxville Tn.

I will show you the transformation in future posts to show how much went into building this car. It is not a bolt together project as nothing is

available to buy to just bolt together a new car and then go race. I started with 4 chalk marks on the floor of my shop to tell where the wheels were going

to be .

The only thing I did not do myself is the machine work on the block and the driveshaft.

I found this car setting in South Carolina in a car port. It had been setting for 10 years waiting to be hot rodded.

Unfortunately the previous owner has cancer and couldn't do the car so I bought the car and took it home to my shop in Florida.

Here is the day I got it home and the day I took it to the first Southeast Gasser race in Knoxville Tn.

I will show you the transformation in future posts to show how much went into building this car. It is not a bolt together project as nothing is

available to buy to just bolt together a new car and then go race. I started with 4 chalk marks on the floor of my shop to tell where the wheels were going

to be .

The only thing I did not do myself is the machine work on the block and the driveshaft.