Was wanting to see if anyone knows how many volts I should see on my tester I put my ground lead from my tester to the bottom hole in my tfi harness plug and the red lead to the positive side on my solonoid and got 7.5 volts I'm thinking I have ground issues somwere. Sometimes my injectors open sometimes they don't. Have tried diffrent distributors with same result. So thinking it might be my tfi harness plug.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Testing The Tfi Plug

- Thread starter GREG91GT

- Start date

-

Sponsors (?)

Thanks you that is a very good article. But I'm just wondering by using the ing gnd witch in your diagram is number 1 and puting my red lead to a 12 volt source should I be seeing 12 volts. Wondering why I'm only seeing 7.5 volts using that ground. Sorry it's kind of confusing.

Is there any way I can test the computer to see if its the drivers that sends the signal to the injectors is working I had a noid light and it showed they were working. But the pulse was more of a constant light not like a timing light and it wasn't real bright. I have checked every ground and cleaned them.

mikestang63

SN Certified Technician

This post may help you. I bookmarked it when I was diagnosing some potential problems. You should pull codes as well so you aren't chasing your tail.

http://www.stangnet.com/mustang-for...timing-advance-code-18-r.876140/#post-8809669

http://www.stangnet.com/mustang-for...timing-advance-code-18-r.876140/#post-8809669

When checking the voltage for the any component, you should always use the engine block or the battery negative ground near the windshield washer filler.

If there is greater than 200 mV difference in the voltage when using a the battery negative ground and the engine block, you have grounding problem.

The red wire for the injectors appears many different places and all of them should read the same 12 volts with the ignition switch in the Run position.

Diagram courtesy of Tmoss & Stang&2birds

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

Grounds

Revised 28-Oct-2012 to add signal ground description & possible problems if it is bad

Grounds are important to any electrical system, and especially to computer controlled engines. In an automobile, the ground is the return path for power to get back to the alternator and battery.

Make sure that all the ground places are clean and shiny bare metal: no paint, no corrosion.

1.) The main power ground is from engine block to battery: it is the power ground for the starter & alternator.

2.) The secondary power ground is between the back of the intake manifold and the driver's side firewall. It is often missing or loose. It supplies ground for the alternator, A/C compressor clutch and other electrical accessories such as the gauges. The clue to a bad ground here is that the temp gauge goes up as you add electrical load such as heater, lights and A/C.

Any car that has a 3G or high output current alternator needs a 4 gauge ground wire running from the block to the chassis ground where the battery pigtail ground connects. The 3G has a 130 amp capacity, so you wire the power side with 4 gauge wire. It stands to reason that the ground side handles just as much current, so it needs to be 4 gauge too.

The picture shows the common ground point for the battery , computer, & extra 3G alternator ground wire as described above in paragraph 2. A screwdriver points to the bolt that is the common ground point.

The battery common ground is a 10 gauge pigtail with the computer ground attached to it.

Picture courtesy timewarped1972

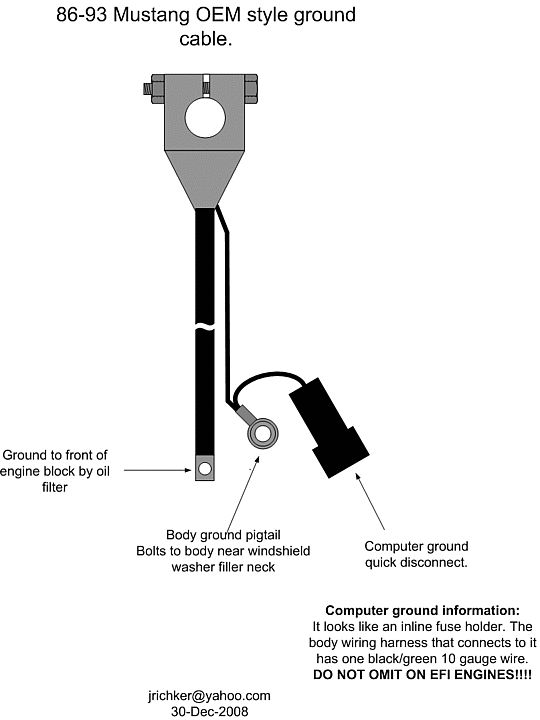

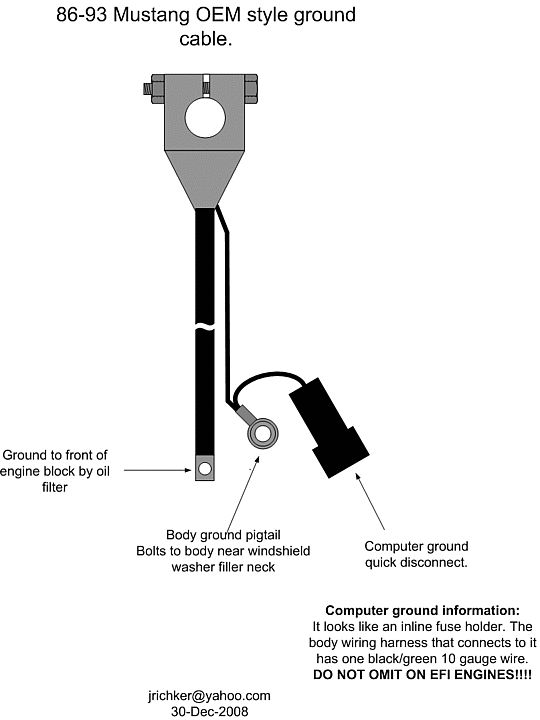

Correct negative battery ground cable.

3.) The computer's main power ground (the one that comes from the battery ground wire) uses pins 40 & 60 for all the things it controls internally: it comes off the ground pigtail on the battery ground wire. Due to its proximity to the battery, it may become corroded by acid fumes from the battery.

In 86-90 model cars, it is a black cylinder about 2 1/2" long by 1" diameter with a black/lt green wire.

In 91-95 model cars it is a black cylinder about 2 1/2" long by 1" diameter with a black/white wire.

You'll find it up next to the starter solenoid where the wire goes into the wiring harness.

All the grounds listed in items 1,2 & 3 need to bolt to clean, shiny bare metal. A wire brush or some fine sandpaper is the best thing to use to clean the ground connections.

4.) All the sensors have a common separate signal ground. This includes the TPS, ACT, EGR, BAP, & VSS sensors. This ground is inside the computer and connects pin 46 to pins 40 & 60, which are the main computer grounds. If this internal computer ground gets damaged, you won't be able to dump codes and the car will have idle/stall/ performance problems

5.) The O2 sensor heaters have their own ground (HEGO ground) coming from the computer. This is different and separate from the O2 sensor ground. It is an orange wire with a ring terminal on it. It is located in the fuel injector wiring harness and comes out under the throttle body. It gets connected to a manifold or bolt on back of the cylinder head.

6.) The TFI module has 2 grounds: one for the foil shield around the wires and another for the module itself. The TFI module ground terminates inside the computer.

7.) The computer takes the shield ground for the TFI module and runs it from pin 20 to the chassis near the computer.

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf for help for help troubleshooting voltage drops across connections and components. Be sure to have the maximum load on a circuit when testing voltage drops across connections. As current across a defective or weak connection, increases so does the voltage drop. A circuit or connection may check out good with no load or minimal load, but show up bad under maximum load conditions. .

Voltage drops should not exceed the following:

200 mV Wire or cable

300 mV Switch

100 mV Ground

0 mV to <50 mV Sensor Connections

0.0V bolt together connections

Extra grounds are like the reserve parachute for a sky diver. If the main one fails, there is always your reserve.

The best plan is to have all the grounds meet at one central spot and connect together there. That eliminates any voltage drops from grounds connected at different places. A voltage drop between the computer ground and the alternator power ground will effectively reduce the voltage available to the computer by the amount of the drop.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/91-93_5.0_EEC_Wiring_Diagram.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

O2 sensor wiring harness

http://www.veryuseful.com/mustang/tech/engine/images/mustangO2Harness.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

HVAC vacuum diagram

http://www.veryuseful.com/mustang/tech/engine/images/Mustang_AC_heat_vacuum_controls.gif

TFI module differences & pin out

http://www.veryuseful.com/mustang/tech/engine/images/TFI_5.0_comparison.gif

Fuse box layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

87-92 power window wiring

http://www.veryuseful.com/mustang/tech/engine/images/mustang87-92 PowerWindowWiring.gif

93 power window wiring

http://www.veryuseful.com/mustang/tech/engine/images/mustang93PowerWindows.gif

Visual comparison of the Ford Fuel Injectors, picture by TMoss:

http://www.veryuseful.com/mustang/tech/engine/images/Ford_Injector_Guide.jpg

If there is greater than 200 mV difference in the voltage when using a the battery negative ground and the engine block, you have grounding problem.

The red wire for the injectors appears many different places and all of them should read the same 12 volts with the ignition switch in the Run position.

Diagram courtesy of Tmoss & Stang&2birds

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

Grounds

Revised 28-Oct-2012 to add signal ground description & possible problems if it is bad

Grounds are important to any electrical system, and especially to computer controlled engines. In an automobile, the ground is the return path for power to get back to the alternator and battery.

Make sure that all the ground places are clean and shiny bare metal: no paint, no corrosion.

1.) The main power ground is from engine block to battery: it is the power ground for the starter & alternator.

2.) The secondary power ground is between the back of the intake manifold and the driver's side firewall. It is often missing or loose. It supplies ground for the alternator, A/C compressor clutch and other electrical accessories such as the gauges. The clue to a bad ground here is that the temp gauge goes up as you add electrical load such as heater, lights and A/C.

Any car that has a 3G or high output current alternator needs a 4 gauge ground wire running from the block to the chassis ground where the battery pigtail ground connects. The 3G has a 130 amp capacity, so you wire the power side with 4 gauge wire. It stands to reason that the ground side handles just as much current, so it needs to be 4 gauge too.

The picture shows the common ground point for the battery , computer, & extra 3G alternator ground wire as described above in paragraph 2. A screwdriver points to the bolt that is the common ground point.

The battery common ground is a 10 gauge pigtail with the computer ground attached to it.

Picture courtesy timewarped1972

Correct negative battery ground cable.

3.) The computer's main power ground (the one that comes from the battery ground wire) uses pins 40 & 60 for all the things it controls internally: it comes off the ground pigtail on the battery ground wire. Due to its proximity to the battery, it may become corroded by acid fumes from the battery.

In 86-90 model cars, it is a black cylinder about 2 1/2" long by 1" diameter with a black/lt green wire.

In 91-95 model cars it is a black cylinder about 2 1/2" long by 1" diameter with a black/white wire.

You'll find it up next to the starter solenoid where the wire goes into the wiring harness.

All the grounds listed in items 1,2 & 3 need to bolt to clean, shiny bare metal. A wire brush or some fine sandpaper is the best thing to use to clean the ground connections.

4.) All the sensors have a common separate signal ground. This includes the TPS, ACT, EGR, BAP, & VSS sensors. This ground is inside the computer and connects pin 46 to pins 40 & 60, which are the main computer grounds. If this internal computer ground gets damaged, you won't be able to dump codes and the car will have idle/stall/ performance problems

5.) The O2 sensor heaters have their own ground (HEGO ground) coming from the computer. This is different and separate from the O2 sensor ground. It is an orange wire with a ring terminal on it. It is located in the fuel injector wiring harness and comes out under the throttle body. It gets connected to a manifold or bolt on back of the cylinder head.

6.) The TFI module has 2 grounds: one for the foil shield around the wires and another for the module itself. The TFI module ground terminates inside the computer.

7.) The computer takes the shield ground for the TFI module and runs it from pin 20 to the chassis near the computer.

See http://assets.fluke.com/appnotes/automotive/beatbook.pdf for help for help troubleshooting voltage drops across connections and components. Be sure to have the maximum load on a circuit when testing voltage drops across connections. As current across a defective or weak connection, increases so does the voltage drop. A circuit or connection may check out good with no load or minimal load, but show up bad under maximum load conditions. .

Voltage drops should not exceed the following:

200 mV Wire or cable

300 mV Switch

100 mV Ground

0 mV to <50 mV Sensor Connections

0.0V bolt together connections

Extra grounds are like the reserve parachute for a sky diver. If the main one fails, there is always your reserve.

The best plan is to have all the grounds meet at one central spot and connect together there. That eliminates any voltage drops from grounds connected at different places. A voltage drop between the computer ground and the alternator power ground will effectively reduce the voltage available to the computer by the amount of the drop.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host) for help on 88-95 wiring http://www.veryuseful.com/mustang/tech/engine/ Everyone should bookmark this site.

Complete computer, actuator & sensor wiring diagram for 91-93 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/91-93_5.0_EEC_Wiring_Diagram.gif

Complete computer, actuator & sensor wiring diagram for 88-91 Mass Air Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/88-91_5.0_EEC_Wiring_Diagram.gif

Ignition switch wiring

http://www.veryuseful.com/mustang/tech/engine/images/IgnitionSwitchWiring.gif

Fuel, alternator, A/C and ignition wiring

http://www.veryuseful.com/mustang/tech/engine/images/fuel-alt-links-ign-ac.gif

O2 sensor wiring harness

http://www.veryuseful.com/mustang/tech/engine/images/mustangO2Harness.gif

Vacuum diagram 89-93 Mustangs

http://www.veryuseful.com/mustang/tech/engine/images/mustangFoxFordVacuumDiagram.jpg

HVAC vacuum diagram

http://www.veryuseful.com/mustang/tech/engine/images/Mustang_AC_heat_vacuum_controls.gif

TFI module differences & pin out

http://www.veryuseful.com/mustang/tech/engine/images/TFI_5.0_comparison.gif

Fuse box layout

http://www.veryuseful.com/mustang/tech/engine/images/MustangFuseBox.gif

87-92 power window wiring

http://www.veryuseful.com/mustang/tech/engine/images/mustang87-92 PowerWindowWiring.gif

93 power window wiring

http://www.veryuseful.com/mustang/tech/engine/images/mustang93PowerWindows.gif

Visual comparison of the Ford Fuel Injectors, picture by TMoss:

http://www.veryuseful.com/mustang/tech/engine/images/Ford_Injector_Guide.jpg

Last edited:

Ok so I messed with the car today and one thing I did was unhook number 5 injector and hooked the injector plug to one of my old 30lb injector I had laying around and cranked the car over and the injector clicked like crazy so I hooked the wire back up to the car injector and it still will not start. The car only starts when it wants to. Lol is there any way it could be a timing/injector timing issue. Was wondering to about the cut mark on my distributor shaft and the cut mark on my block do they suppose to be lined up or just close. Thanks for any help

Try swapping the ignition coil for a new one or a known good one. I had a similar problem where I had spark, but it wasn't the fat blue spark that is what is needed. The coil is only about $13-$17 and you may be able to take it back if it doesn't fix the problem.

The external marks on the distributor aren't real significant. What you see when you put a timing light on the car and see where the pointer lines up when the car is cranking with the ignition on or running, that is important.

The external marks on the distributor aren't real significant. What you see when you put a timing light on the car and see where the pointer lines up when the car is cranking with the ignition on or running, that is important.

Last edited:

Well tried a diffrent coil same thing happened it started I let it run for about 5 min and it wouldn't restart so I checked number 5 spark plug and it was dry. So I sprayed a little gas in the throttle body and it started right up and ran for about 5min and I shut it back off and it wouldn't restart again so I primed it again and it restarted again. So my problem is fuel. First thing I thought of when this problem started was the pip so I took a dizzy out of my buddies car and it does the same thing. I ran the codes and get 85,11,34 the 85 I understand because I no longer have my canister

Have you had any success in checking the grounds, especially the computer power ground?

When it won't restart, check the fuel pressure.

Buy, borrow, or beg a fuel pressure test gauge. Most auto parts stores will rent/loan one if you have a credit card.

Disconnect the vacuum line from the fuel pressure regulator. Check it for evidence of fuel present in the line by removing it and blowing air through it. If you find fuel, the fuel pressure regulator has failed. Reinstall the line; leave the fuel pressure regulator end of the vacuum line disconnected. Then cap or plug the open end of the vacuum line and stow it out of the way.

Connect the fuel pressure test gauge to the Schrader port located just behind the alternator.

Turn the ignition switch on & start the engine. Observe the pressure: you should see 37-41 PSI at idle.

Turn the ignition off; reconnect the vacuum line to the fuel pressure regulator. Then disconnect the fuel pressure test gauge. Watch out for squirting gas when you do this.

When it won't restart, check the fuel pressure.

Buy, borrow, or beg a fuel pressure test gauge. Most auto parts stores will rent/loan one if you have a credit card.

Disconnect the vacuum line from the fuel pressure regulator. Check it for evidence of fuel present in the line by removing it and blowing air through it. If you find fuel, the fuel pressure regulator has failed. Reinstall the line; leave the fuel pressure regulator end of the vacuum line disconnected. Then cap or plug the open end of the vacuum line and stow it out of the way.

Connect the fuel pressure test gauge to the Schrader port located just behind the alternator.

Turn the ignition switch on & start the engine. Observe the pressure: you should see 37-41 PSI at idle.

Turn the ignition off; reconnect the vacuum line to the fuel pressure regulator. Then disconnect the fuel pressure test gauge. Watch out for squirting gas when you do this.

Last edited:

I have cleaned my ground on the inner fender well and the one under the computer and I have a fuel presure gauge hooked up to me Schader valve and got good fuel presure and I have pulled the vacum hose off the fpr to and it don't smell of gas. I just keep thinking its the computer. I can point my rotor at number 5 plug wire on my cap and turn the key on and loosen the dizzy up and turn it left to right ang when the fuel pump kicks on and off the number 5 spark plug fires but the number 4 injector clicks like its opening so I did the same test on the number 1 spark plug and it seems like number 4 injector still clicks maybe I'm doing something wrong I don't know. Thanks for your help

Did you build this car yourself or by up someone's project? It helps to understand what might have been done to the car before you got it.

Look at the paper sticker on the end of the computer. You should see A9L, or A3M: those are 5 speed computers. A9P and C3W are auto trans computers.

Look at the paper sticker on the end of the computer. You should see A9L, or A3M: those are 5 speed computers. A9P and C3W are auto trans computers.

Similar threads

- Replies

- 25

- Views

- 2K

- Replies

- 26

- Views

- 1K

- Replies

- 0

- Views

- 899

- Replies

- 22

- Views

- 2K