Let me start off by saying I know there is a surging idle checklist somewhere, and I'm not trying to avoid using it out of laziness. I'm just hoping that before I start with that, I can eliminate some possible items or get pointed in the direction of some that seem more likely.

I have an '89 LX (stock high mileage motor except for Vortech V3 SCi kit, and full catless exhaust) that has a very intermittent idle issue. 90% of the time it's totally fine, idling around 700 or so. But every once in a while (could be as often as a few times a week, or sometimes goes months without any issues at all) one of a few weird things happens, not seeming to correspond with any certain conditions:

a) At a stoplight or elsewhere idling in neutral, idle will rise up to 1200-1400 and just hang there, lasting anywhere from a few minutes to the entire rest of my drive (up to 20-30min is the longest I've noticed). During this time if I'm driving and push in the clutch or shift into neutral, revs will drop very slowly to the 1200-1400 point

b) A less extreme, and more surgey version of (a).

c) A handful of times, starting the car up cold, as soon as the motor turns over it jumps up to 2000rpm and stays for a good 30-40 seconds (much more aggressive than the occasional slightly high idle to warm up) (quite alarming at 8am)

A few times when it's idling high, I've noticed the motor will have a tiny "cough" or "stumble" and a very brief drop in rpms (I always imagine somebody running too fast while they're half asleep and accidentally catching their shoulder on a doorway).

Other things that may or may not have any connection with this issue:

a) intermittent check engine light (flashes quickly or lasts for a few seconds). Maybe a quick flash every 5-10min, sometimes more frequently. (Also doesn't seem to be related to any particular conditions).

b) ran self-test, and has codes 31 and 53 in CM. I've seen 31 refer to an EGR issue and also an EVP issue, not sure which in my case. 53 I believe is TPS voltage too high. Not sure if the intermittent flashes of the check engine light are due to one, or both, of these.

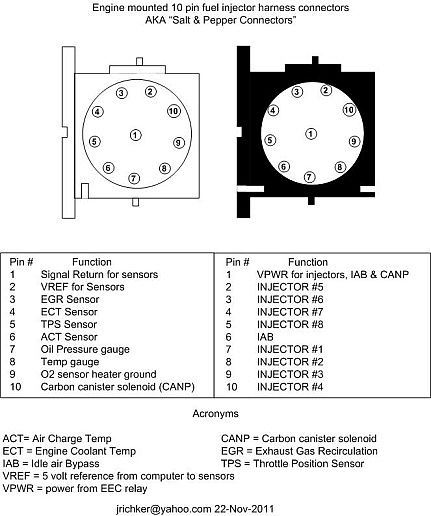

I've checked the TPS voltage and it was set where recommended (around .9-1.0v, it was a few months ago when I did this). I cleaned the salt and pepper connectors. I cleaned the IAC, thinking maybe it was spazzing out. I'm hoping this peculiar combination of issues and codes might help people point me in a particular direction.. when it idles high it gives me anxiety.. Thanks in advance I know it's a lot to read.

I have an '89 LX (stock high mileage motor except for Vortech V3 SCi kit, and full catless exhaust) that has a very intermittent idle issue. 90% of the time it's totally fine, idling around 700 or so. But every once in a while (could be as often as a few times a week, or sometimes goes months without any issues at all) one of a few weird things happens, not seeming to correspond with any certain conditions:

a) At a stoplight or elsewhere idling in neutral, idle will rise up to 1200-1400 and just hang there, lasting anywhere from a few minutes to the entire rest of my drive (up to 20-30min is the longest I've noticed). During this time if I'm driving and push in the clutch or shift into neutral, revs will drop very slowly to the 1200-1400 point

b) A less extreme, and more surgey version of (a).

c) A handful of times, starting the car up cold, as soon as the motor turns over it jumps up to 2000rpm and stays for a good 30-40 seconds (much more aggressive than the occasional slightly high idle to warm up) (quite alarming at 8am)

A few times when it's idling high, I've noticed the motor will have a tiny "cough" or "stumble" and a very brief drop in rpms (I always imagine somebody running too fast while they're half asleep and accidentally catching their shoulder on a doorway).

Other things that may or may not have any connection with this issue:

a) intermittent check engine light (flashes quickly or lasts for a few seconds). Maybe a quick flash every 5-10min, sometimes more frequently. (Also doesn't seem to be related to any particular conditions).

b) ran self-test, and has codes 31 and 53 in CM. I've seen 31 refer to an EGR issue and also an EVP issue, not sure which in my case. 53 I believe is TPS voltage too high. Not sure if the intermittent flashes of the check engine light are due to one, or both, of these.

I've checked the TPS voltage and it was set where recommended (around .9-1.0v, it was a few months ago when I did this). I cleaned the salt and pepper connectors. I cleaned the IAC, thinking maybe it was spazzing out. I'm hoping this peculiar combination of issues and codes might help people point me in a particular direction.. when it idles high it gives me anxiety.. Thanks in advance I know it's a lot to read.