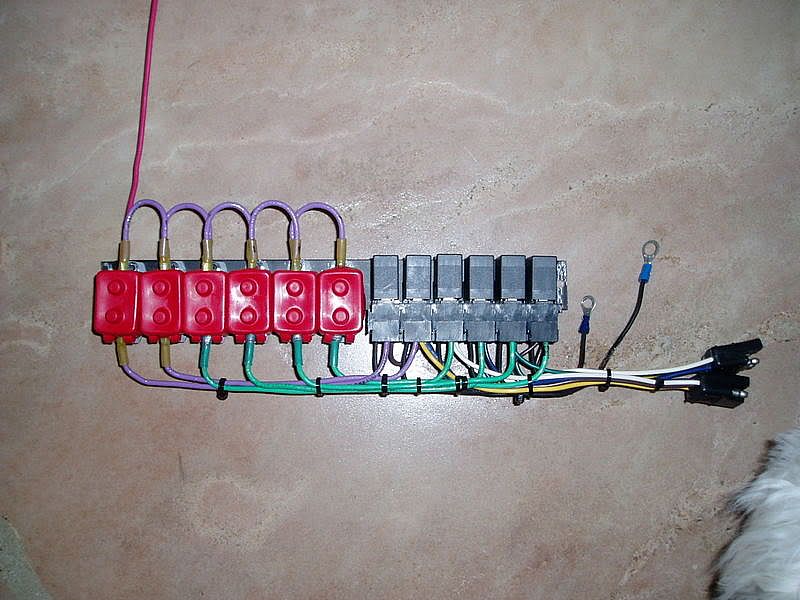

Finishing up the wiring (except for the gauges and center console), I checked all the relays and circuits. Horn works, high beams, low beams, fog lights, A/C works (blower 3 speeds and electrical to the switch on the pressure side of the cooler for the compressor clutch), back up lights (with the trans circuit bypassed), starter solenoid (with the neutral switch bypassed), all blinker, interior lights, dome, trunk light (it is always hot, I need a switch and light), fuel pump, and optional relay to stereo amp!

I started work on the gauge cluster. I installed the windshield wiper switch (no new replacement, had to use the old one)

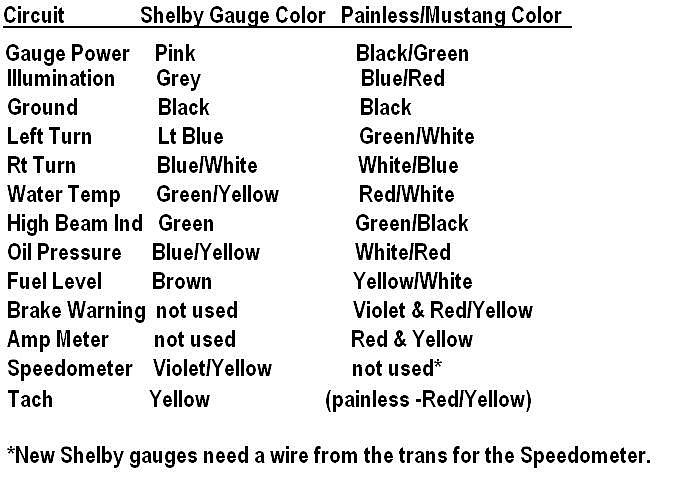

and I will post a schematic of the new Shelby gauge cluster wiring that has to be cut off and adapted to the new Painless harness tomorrow (circuit, Shelby color, painless color). Here is a start

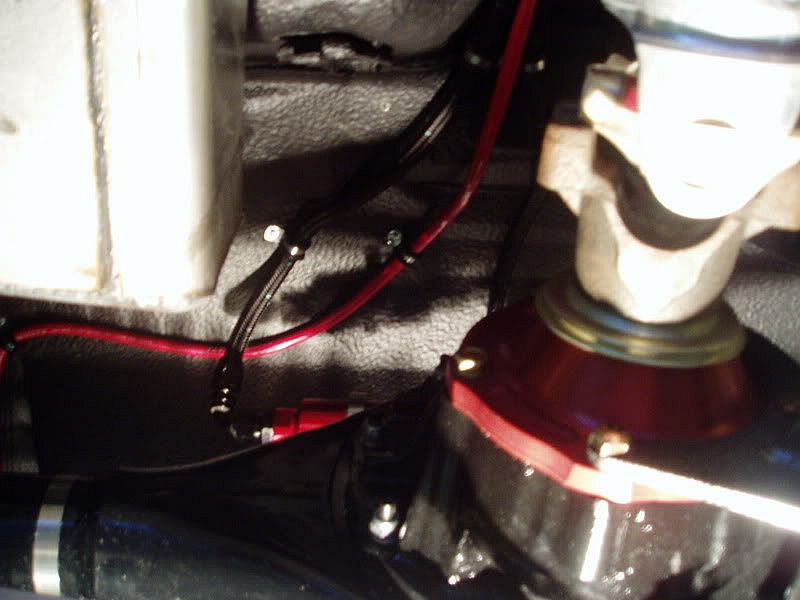

And I installed the oil cooler.