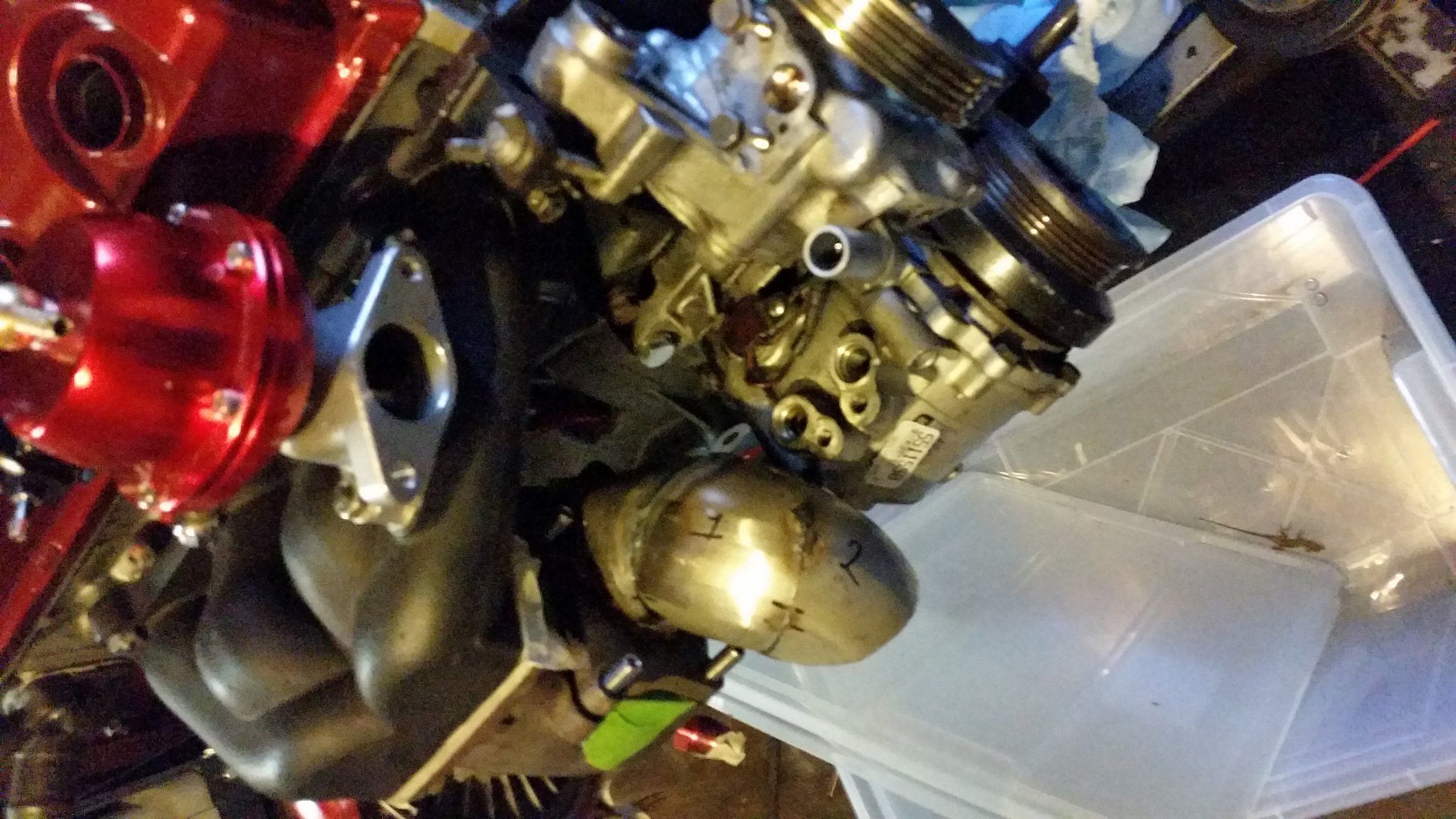

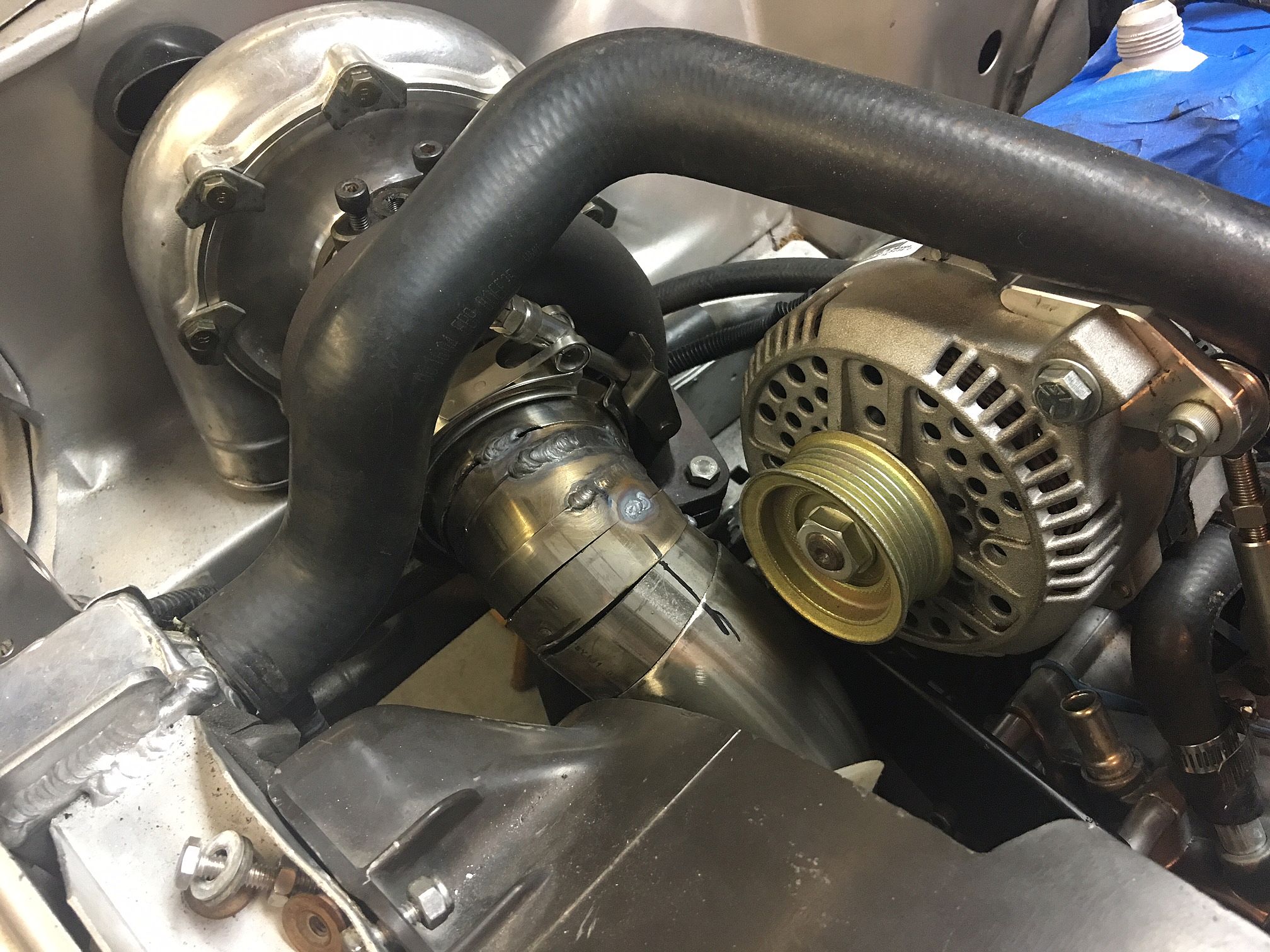

Does the turbo touch the panel?

I'm as far as I can get without buying stuff. Gonna have to wait for a bit.

Edit* well, I guess I can start plumbing the cold side.

Looks badass man

Does the turbo touch the panel?

I'm as far as I can get without buying stuff. Gonna have to wait for a bit.

Edit* well, I guess I can start plumbing the cold side.

I'm as far as I can get without buying stuff. Gonna have to wait for a bit.

Edit* well, I guess I can start plumbing the cold side.

Does the turbo touch the panel?

Looks badass man

Looks killer! How's hood clearance looking? I'm gonna be impressed as heck with you if that all fits under the stock hood... Then, I get to copy you!

So, no - The elbow does not fit under the hood as it sits. Also, the attachment point for the TB linkage already hits the valve cover, so I'm going to need a 1" spacer to boot.

Helloooooo reciprocating saw.

You're going to chop your hood open?

You're going to chop your hood open?Well, I can't afford to buy/paint a cowl right now. Gonna do something like this:You're going to chop your hood open?

Buddies been 8.51 . Stock rod and crank . .30 over piston . Victor juniors , gt40 lower , downs upper . 76 mm turbo 60 lb injectors and a Pms . On a stock 79 w blockBTW - That's the car I based my build on. 8s on a stock bottom end. I think it now has forged pistons and chinee rods, but it's still very mild and runs haaard

I happen to think if executed correctly it will look sinisterBTW - That's the car I based my build on. 8s on a stock bottom end. I think it now has forged pistons and chinee rods, but it's still very mild and runs haaard

But, with that said, I am going to finish welding it up this weekend and it may actually turn out half decent. Or I may go buy a chop saw and do it all over again. I could make magic with straight cuts and measurable angles, I swear!

But, with that said, I am going to finish welding it up this weekend and it may actually turn out half decent. Or I may go buy a chop saw and do it all over again. I could make magic with straight cuts and measurable angles, I swear!

I feel like that picture was expectation.....reality comparison. Also, if your worried about the way it looks, look a sloppymechanics builds on youtube, he's used junk piping and crappy steel and made 700 horsepower on the junk. Then he spent money for a cleaner look and lost hp.....irony some times

Looking good, keep it up