You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Updating my oil pump

- Thread starter lakespeed

- Start date

-

Sponsors (?)

manicmechanic007

5 Year Member

I disagree with high-volume oil pumps for blocks not specifically designed/set up for them.

There's nothing at all [wrong] with the standard volume pump. How many years has it kept your engine running? The OEM piece probably has a pretty good track record. I would replace it with one just like it from an OEM manufacturer (not Chinese).

High volume oil pumps on otherwise stock engines have the potential to fill the top portion of the engine faster than it can efficiently drain to the oil pan. My DART block has additional oil plugs that are supposed to be removed when running an HV pump.

My engine is a street combo, 347, Twin Screw supercharger, 500+ crank HP, and a standard volume oil pump.

I am not aware of any significant advantage to running an HV pump on a street or street/strip combo. I can see an argument for a road course build but they tend to be high/long revving applications and lots of turns.

The real-world downsides to running HV pumps on otherwise stock engines that I've come across include combos with huge catch-cans and oil finding its way into the intake through the PCV system or other.

For most, they're a solution to a problem that doesn't exist and can sometimes create issues of their own.

There's nothing at all [wrong] with the standard volume pump. How many years has it kept your engine running? The OEM piece probably has a pretty good track record. I would replace it with one just like it from an OEM manufacturer (not Chinese).

High volume oil pumps on otherwise stock engines have the potential to fill the top portion of the engine faster than it can efficiently drain to the oil pan. My DART block has additional oil plugs that are supposed to be removed when running an HV pump.

My engine is a street combo, 347, Twin Screw supercharger, 500+ crank HP, and a standard volume oil pump.

I am not aware of any significant advantage to running an HV pump on a street or street/strip combo. I can see an argument for a road course build but they tend to be high/long revving applications and lots of turns.

The real-world downsides to running HV pumps on otherwise stock engines that I've come across include combos with huge catch-cans and oil finding its way into the intake through the PCV system or other.

For most, they're a solution to a problem that doesn't exist and can sometimes create issues of their own.

manicmechanic007

5 Year Member

@lakespeed why are you updating the oil pump?

A HV oil pump can be a band aid for loose bearings. A HP or HV pump can help when running an external oil cooler. Generally they take power that could be used to turn the tires. But your gauge looks good.

The emptying of the pan because of filling the heads with the oil and slow drain back would require extended high rpm useage, maybe circle track use.

A HV oil pump can be a band aid for loose bearings. A HP or HV pump can help when running an external oil cooler. Generally they take power that could be used to turn the tires. But your gauge looks good.

The emptying of the pan because of filling the heads with the oil and slow drain back would require extended high rpm useage, maybe circle track use.

And which engine was Q in 73?@lakespeed why are you updating the oil pump?

A HV oil pump can be a band aid for loose bearings. A HP or HV pump can help when running an external oil cooler. Generally they take power that could be used to turn the tires. But your gauge looks good.

The emptying of the pan because of filling the heads with the oil and slow drain back would require extended high rpm useage, maybe circle track use.

Mcmahst

Active Member

Before having an opinion on oil pumps, you should watch this Engine Masters episode on oil pumps, it was very interesting:

CAMTWO1070

Active Member

Theres lots of contradicting info when it comes to oilpumps and engines with mileage on them.

Usually you can adjust the thickness of the oil to make up for the loss in pressure due to the extra clearances and adjust the operating temps say going fron a 180 degree thermostat to a 170 degree thermostat.

High volume pumps deliver a mere 15-20% extra oil and when you have an engine thats running 5-10lbs hot at idle that 15-20% extra pressure can help prolong the life of the engine.

When you rebuild an engine its very important to know bearing clearances for the whole rotating assembly as the rod,main camshaft bearing aswell as lifter bore clearances dictates the viscosity of oil and whether a HV oilpump is warranted from the getgo.

Lots of experts in the field say if the crank is running stock bearings everywhere with stock or slightly tighter than stock tolerances a regular oilpump will suffice but in a fresh rebuild with a crank thats undercut say .010" with a couple extra thousandths in the lifter bores that adds to excessive bleed off and in this case Id use a HV oilpump and not drive it so hard...

Another instance is in my newest 410 stroker build...Same brutal torque build-up as the 408 and seeings I hate using roller camshafts even though they alleviate friction in the upper valvetrain they are also prone to failures due to quality control issues concerning roller lifters and lifter bars not doing their job on everyday street driven vehicles with non-roller blocks so instead I went with a set of EDM style extra oiling lifters that have a tiny hole lasered into the bottom centers of the lifters to force oil between the flat tappet hydraulic lifter and the camshaft lobe essentially alleviating rotating friction in the valvetrain aswell but those type of lifters will also tax a stock oilpump so in this case a HV/ High pressure pump is warranted and to do the job Im using one from Milodon in my 8qt Canton oilpan w/crank scraper and slosh baffle to control windage and oil return back to the pickup..

I'm also making up for the friction of a hydraulic flattappet camshaft by using a set of shaft mounted roller rockers.............On the 408w I ram Comp Cams pro Magnum Steel full roller rockers w/7/16" studs and stud girdle but they were a tad too noisy for my liking after a 40-45 mile run...

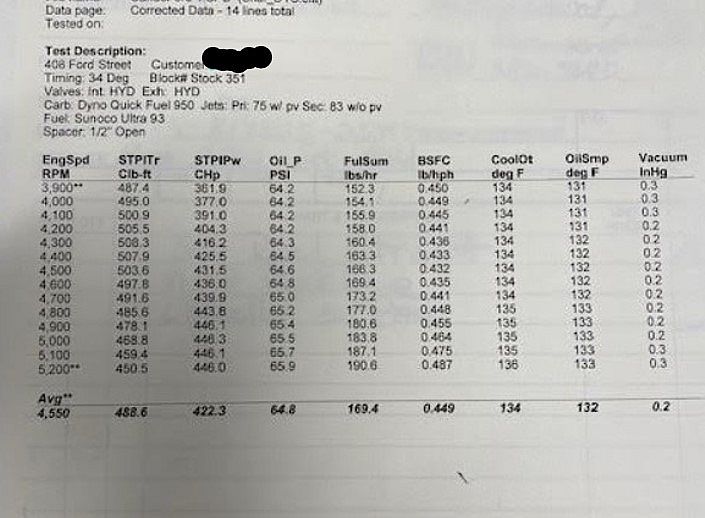

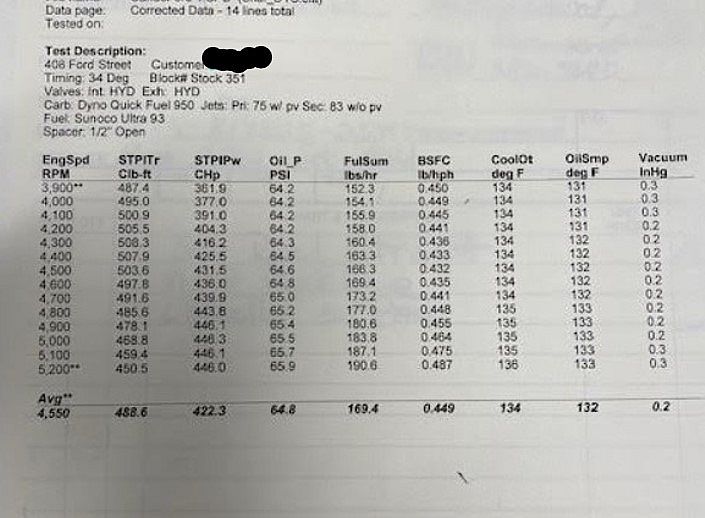

Im even running Edelbrock E-Street heads with the smaller valves yet on a carb on a dyno first pull the flat tappet hydraulic .477/.493" lift camshaft made this kind of power after breaking in the camshaft...Then with my EFI Performer intake that according to Edelbrock delivers an extra 40ftlbs more torque with my performance tune it was closer to an extra 60ftlbs more and the brutal torque came on a lil earlier too............LOL

I plan on breaking the 410w in on Driven 5w/30 conventional break-in oil with ZDDP additive and running it on 5w/20 Amsoil after break-in to keep the distributor gear from prematurely wearing from excessive pressure then as engine wears and pressure starts to drop simply adjust oil viscosity.....

But in the end of my speil like I stated there are reasons and rules to the exceptions...

Another exception to the stock bearing stock clearance stock pump rule is if youre using an oil cooler youll need a high volume/high pressure oil pump aswell..

Usually you can adjust the thickness of the oil to make up for the loss in pressure due to the extra clearances and adjust the operating temps say going fron a 180 degree thermostat to a 170 degree thermostat.

High volume pumps deliver a mere 15-20% extra oil and when you have an engine thats running 5-10lbs hot at idle that 15-20% extra pressure can help prolong the life of the engine.

When you rebuild an engine its very important to know bearing clearances for the whole rotating assembly as the rod,main camshaft bearing aswell as lifter bore clearances dictates the viscosity of oil and whether a HV oilpump is warranted from the getgo.

Lots of experts in the field say if the crank is running stock bearings everywhere with stock or slightly tighter than stock tolerances a regular oilpump will suffice but in a fresh rebuild with a crank thats undercut say .010" with a couple extra thousandths in the lifter bores that adds to excessive bleed off and in this case Id use a HV oilpump and not drive it so hard...

Another instance is in my newest 410 stroker build...Same brutal torque build-up as the 408 and seeings I hate using roller camshafts even though they alleviate friction in the upper valvetrain they are also prone to failures due to quality control issues concerning roller lifters and lifter bars not doing their job on everyday street driven vehicles with non-roller blocks so instead I went with a set of EDM style extra oiling lifters that have a tiny hole lasered into the bottom centers of the lifters to force oil between the flat tappet hydraulic lifter and the camshaft lobe essentially alleviating rotating friction in the valvetrain aswell but those type of lifters will also tax a stock oilpump so in this case a HV/ High pressure pump is warranted and to do the job Im using one from Milodon in my 8qt Canton oilpan w/crank scraper and slosh baffle to control windage and oil return back to the pickup..

I'm also making up for the friction of a hydraulic flattappet camshaft by using a set of shaft mounted roller rockers.............On the 408w I ram Comp Cams pro Magnum Steel full roller rockers w/7/16" studs and stud girdle but they were a tad too noisy for my liking after a 40-45 mile run...

Im even running Edelbrock E-Street heads with the smaller valves yet on a carb on a dyno first pull the flat tappet hydraulic .477/.493" lift camshaft made this kind of power after breaking in the camshaft...Then with my EFI Performer intake that according to Edelbrock delivers an extra 40ftlbs more torque with my performance tune it was closer to an extra 60ftlbs more and the brutal torque came on a lil earlier too............LOL

I plan on breaking the 410w in on Driven 5w/30 conventional break-in oil with ZDDP additive and running it on 5w/20 Amsoil after break-in to keep the distributor gear from prematurely wearing from excessive pressure then as engine wears and pressure starts to drop simply adjust oil viscosity.....

But in the end of my speil like I stated there are reasons and rules to the exceptions...

Another exception to the stock bearing stock clearance stock pump rule is if youre using an oil cooler youll need a high volume/high pressure oil pump aswell..

Attachments

manicmechanic007

5 Year Member

Some of you have never seen a oil pressurized engine leak oil out the main, rod and cam bearings with the pan off I take it

So to me your opinion against a high volume pump is about as worthless as tits on a boar

The OP said upgrade

I will be running a high volume oi; pump n every motor I build no matter what the mains and rods clearance

A high volume pump which big pressure if the oil has no place to go

If the oi; pressure is less than 80 lbs that is great

So to me your opinion against a high volume pump is about as worthless as tits on a boar

The OP said upgrade

I will be running a high volume oi; pump n every motor I build no matter what the mains and rods clearance

A high volume pump which big pressure if the oil has no place to go

If the oi; pressure is less than 80 lbs that is great

The OP has not been back since making the initial post.

Continue to debate if you wish.

Continue to debate if you wish.

Similar threads

- Replies

- 1

- Views

- 160

- Replies

- 6

- Views

- 611

- Replies

- 1

- Views

- 528

Electrical

Oil Pressure gauge issues

- Replies

- 2

- Views

- 293

- Replies

- 1

- Views

- 380