- Sep 2, 2016

- 51

- 2

- 8

So here's what I'm working with

Stock bottom end

Performer heads

Dss 1.72 rr's (pedestal Mount)

Hydraulic roller lifters

Xe270hr cam (.512 lift)

New springs to match cam

My 6.3" pushrods will torque to spec at 1/4 turn on the rocker arms with a .040" shim. However, the cover across the valve stem seems too long and is on the top third of the valve stem. I used my pushrod tool and determined I needed a 6.5" pushrod to get the cover in the middle of the valve.

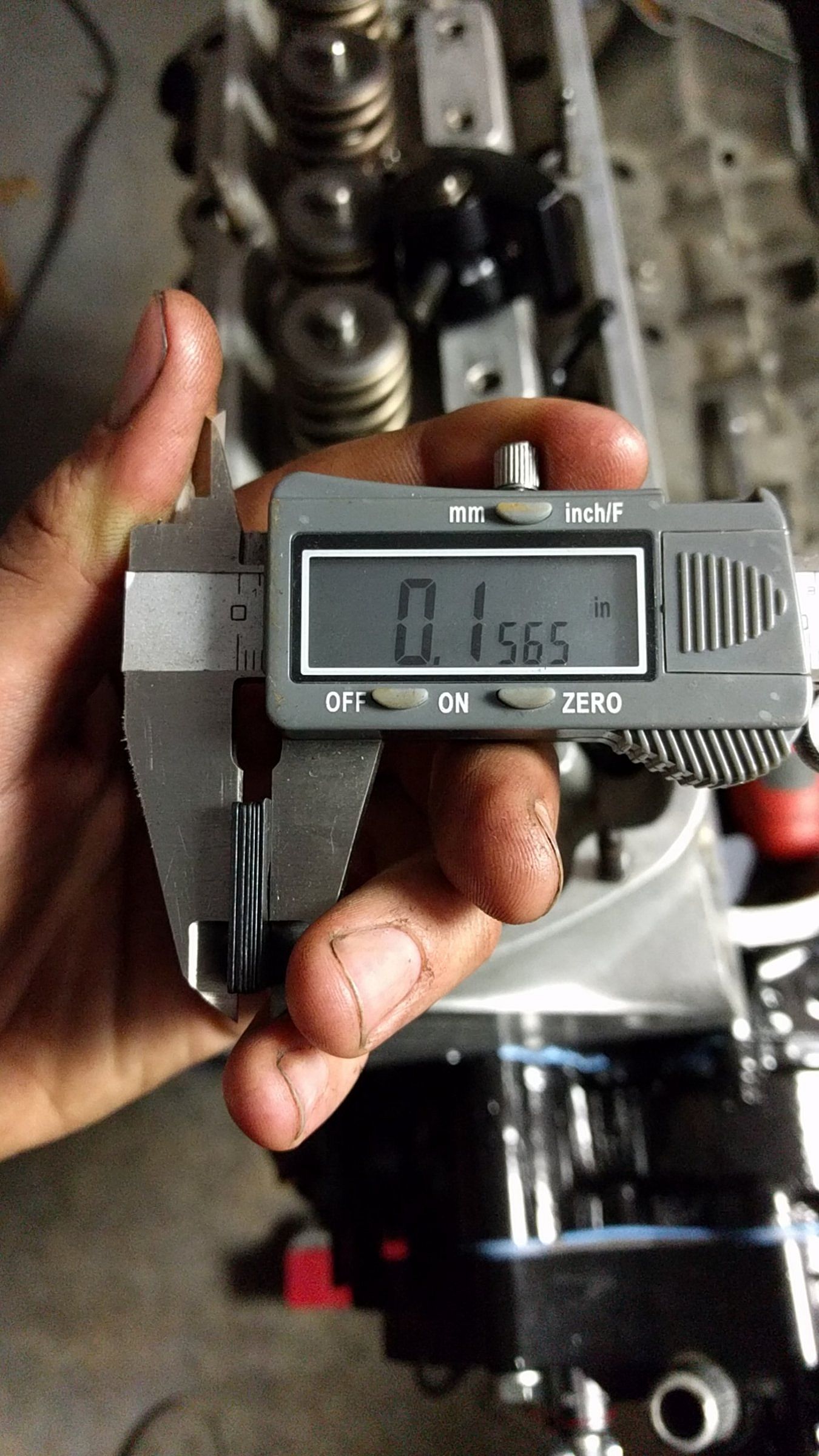

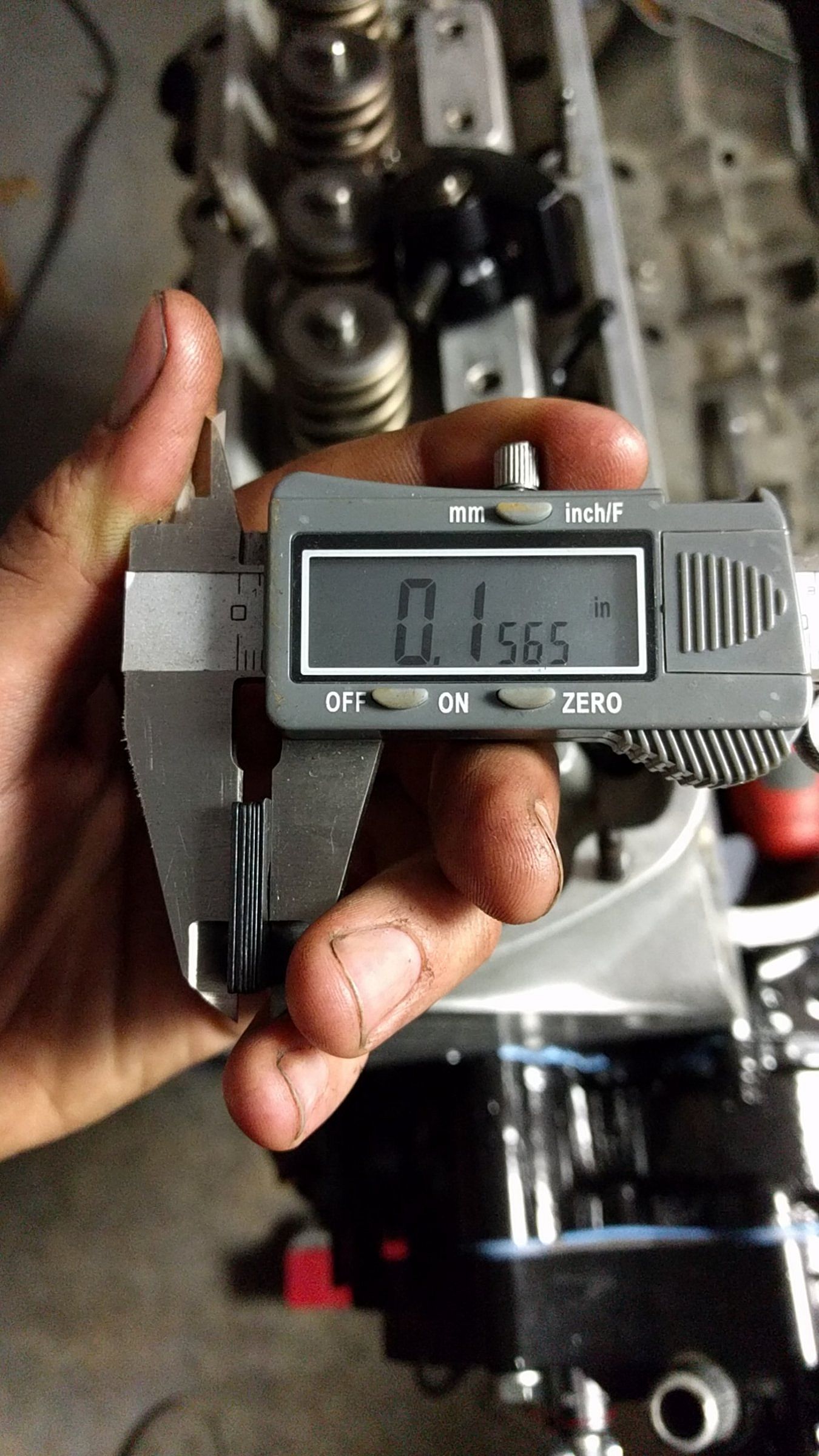

Problem here is that i can only get my rocker arm to torque with my shims stacked to .150" high!! What am I missing/doing wrong here?

First picture is my shim stack

2nd pic is cover with 6.3" rod

3rd is 6.5" rod. (Torqued on the .150" shim stack)

Any input helps! This is my first engine build

Stock bottom end

Performer heads

Dss 1.72 rr's (pedestal Mount)

Hydraulic roller lifters

Xe270hr cam (.512 lift)

New springs to match cam

My 6.3" pushrods will torque to spec at 1/4 turn on the rocker arms with a .040" shim. However, the cover across the valve stem seems too long and is on the top third of the valve stem. I used my pushrod tool and determined I needed a 6.5" pushrod to get the cover in the middle of the valve.

Problem here is that i can only get my rocker arm to torque with my shims stacked to .150" high!! What am I missing/doing wrong here?

First picture is my shim stack

2nd pic is cover with 6.3" rod

3rd is 6.5" rod. (Torqued on the .150" shim stack)

Any input helps! This is my first engine build