I'll bet money he didn't. No hydraulic lifters, a great sump, and lots of flow and capacity.Did you lose oil pressure???

Great engineering Mike!

I'll bet money he didn't. No hydraulic lifters, a great sump, and lots of flow and capacity.Did you lose oil pressure???

A little late in response to this....I was out drag racing....anywho, I use an electric smog pump to act as a evac pump for the crankcase. It works great, no oil leaks. Just a thought.There isn't one available inch of space for any additional belt driven accessory.

What car is that off of, and how noisy is it?A little late in response to this....I was out drag racing....anywho, I use an electric smog pump to act as a evac pump for the crankcase. It works great, no oil leaks. Just a thought.

The pump application is 99-02 Camaro/Firebird. I picked one up at NAPA 4 years ago for around $80 with a lifetime warranty. Noise wise would depend on how the discharge from the pump is routed. Mine just dumps straight to atmosphere so it makes a bit of noise, but you can not hear it over the exhaust. I have it mounted up inside the inner fender, near where the antenna would be. The oil separator is mounted in the front side of same fender. -10 AN hose from front of V/C to oil separator, out of that to smog pump.

Mike you are showing your age... You remember the days when the auto parts counterman was an auto mechanic on the side and fixed his own car and the cars of his family and friends.

These kids now days are qualified because they know how to use a computer well enough to do Facebook and play games online.

They may not know diddly about cars and car parts and if it isn't easily found in the store computer it just doesn't exist for them.

Word of warning about plastic or nylon insert self-locking nuts for my days as an aircraft mechanic. The plastic and nylon insert self-locking nuts are only good to 250 ° F.

With a turbo to heat up all the air in your engine compartment, I would recommend that you use full metallic self-locking nuts on anything that might vibrate loose.

FastenalAnd I'll heed your advice. I gotta get to a real nut/ bolt house...the nylon nuts were all that lowes had.

Well hell.

Fail, fail fail.......that's the way today went.

After reading @Bullitt347 's reply, this morning, I set out to build that system. I got online, found a model number for a electric smog pump, found a resource for how to build a killer system,..and set out.

I called Oreillys. I had the model number.......yet the new kid at the counter ( who had never heard if a smog pump before) could not find it. When I showed him the piece online, he finally finds it. But their price is more than two times as high as the online part.

I finally find one, but it's still gonna cost me over 140 plus tax for just the pump...and I still had to make a catch can..I called my friend that has been using these things in the past to see if he had an old dead one I could use as a core,..and he talks me out of it. He tells me that I'll never offset the crankcase pressure w/ one of these things as they are only capable of about 5" of vacuum at 12v.

Perfect.

I decide to go low instead...I'm back to trying to see if the exhaust will pull the vacuum I need...I mean it makes sense when compared to the set speed if the electric smog pump....my exhaust will speed up as engine RPM increases...if there is vacuum at idle, and low speed,..I should be able to do this w/o tapping another electric circuit.

So I go to lowes, and spend 85 bucks on the stuff required to build a catch can, and allow me to tap my exhaust for the required vacuum nipples.

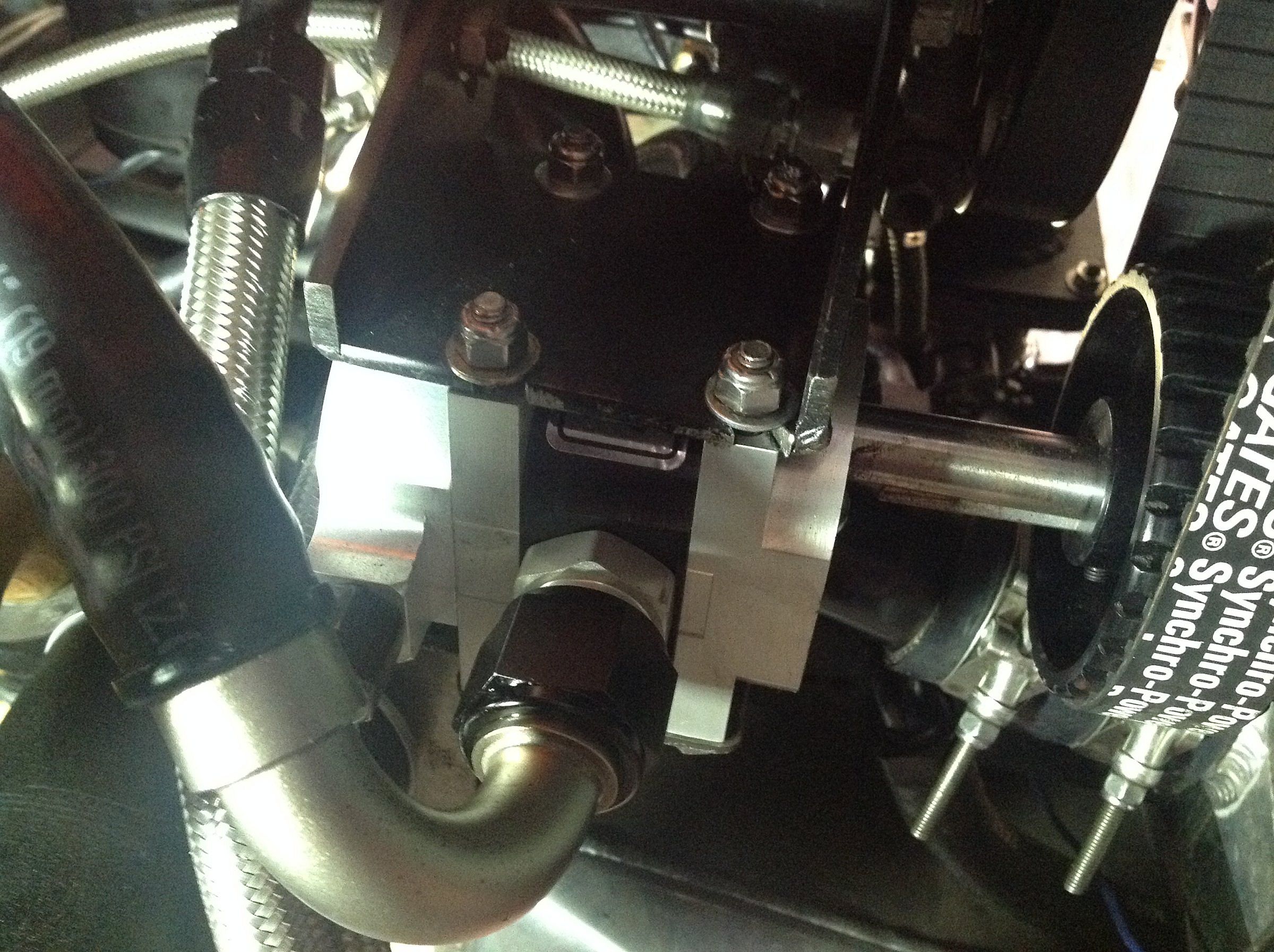

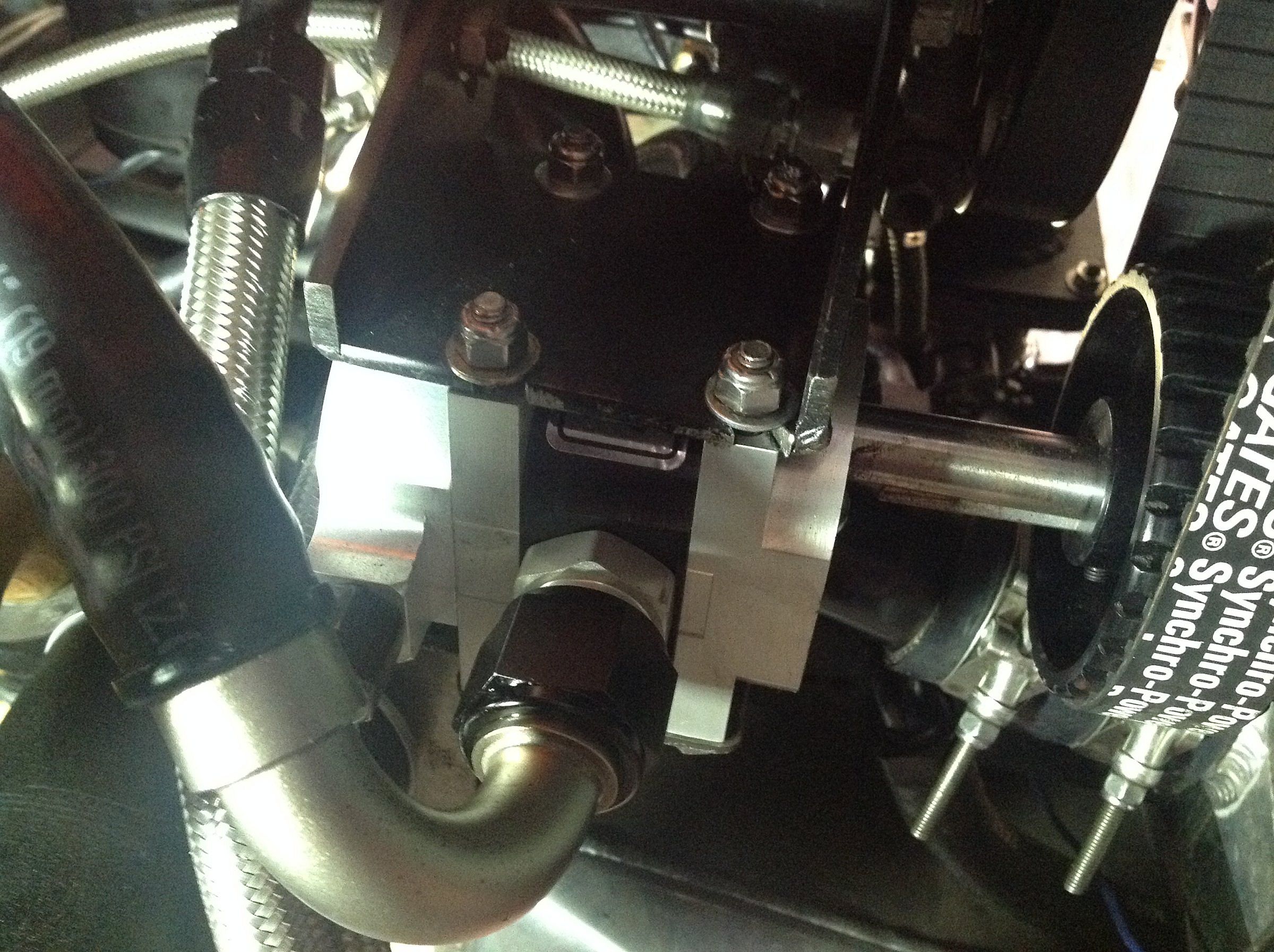

But first things first......I fixed my dangling oil pump.

Now secured by lock nuts, as opposed to regular pieces,..hopefully that'll never come loose again.

Then, I went about making the pipe nipples that I'll have to attach -10 hoses to. That required two big assed holes in my exhaust,..and then weld these dorky steel penise lookin pieces of pipe in at an angle that will hopefully be conducive to creating a siphon ( What's the law of physics here?......the Venturi effect?)

For whatever reason though,...I completely forgot about the one way valves......I guess I was gonna try and stick PCV valves inline to stop positive exhaust pressure from charging the canister...but though better of that after thinking about it for a minute.

I got online again, thinking surely,..this thing has to be an OEM part, and sure enough found it just as quickly. Dorman PN 355-050...15.00 bucks each.

I call Oreillys, give dude the PN again,..he tells me that it's a screw.

" No, it's a smog air pump check valve" I tell him..he tells me that he can only go by what his computer tells him..

IS THERE ANY WORSE AUTO PARTS STORE ON EARTH THAN THE OREILLYS STORE IN IRONDALE ALABAMA????

I give up, call Advance..they'd have to special order it.

I resign myself to not being able to finish,..I reinstall the exhaust, call summit,..give them the PN,..they tell me that they have them in stock, and will ship out today, probably arrive tomorrow.

Send them to me....30 dollars plus 10.00 shipping.

What else can I do? I need the damn things.

Tomorrow I gotta finish the canister,...and get it mounted. I hope this works.

If it don't, I'll plug the two nipples in the exhaust,..and burn the car to the ground.

Ok mike, I’ve got to relate this to a paint gun.So I'm sitting here...knees on ice,..day two of dickin with the crankcase evade system..

Dig if you will a picture,...of you and I engaged in this tiff...

( in other words...imagine this

I build a catch can out of 3" PVC. I cap it on both ends. Inside there is a divider baffle that hopefully will minimize wet oil just going through one side, and exiting straight out into my exhaust.

There is one -12 inlet,..and two -10 outlets plumbed directly into the exhaust system.

When you blow on the end that looks like a hose nipple, there is almost zero resistance to passing straight through. When you blow on the other end, it's blocked....so, this thing is a check valve. There are two of these things screwed onto my exhaust with two pieces of 5/8" heater hose going back to my canister.

On top of my canister is a PCV valve w/1/2" hose plumbed to a inlet before the throttle body. On the bottom of my canister is a pipe plug, so I can drain the thing.

When I performed my vacuum test today to determine if the exhaust would pull a vacuum on the sealed canister, I get nothin....Zero inches of vacuum at idle in that canister.

Phck me all to hell.

I reason forward. Since you can literally blow through those check valves, any positive pressure in that canister will escape in the exhaust stream..I'm thinking (hoping) that once under boost, the crankcase pressure that pushes into the exhaust will start a siphon....(cause the exhaust gases that'll be moving through that exhaust under boost should be moving a hell of a lot faster than they were at idle).

The PCV valve on top of the canister should be forced shut under boost, but all other times when cruising and idling, should be free to suck the crankcase vapors back into the intake tract...

Does this make any sense?

Obviously,..I didn't extend my tip deep enough.Ok mike, I’ve got to relate this to a paint gun.

Pretend your exhaust flow (pressure outlet that your trying to achieve vacuum from) is the air holes in the cap when you pull the trigger. If your fluid tip isn’t actually in that stream of moving air, when you pull the trigger the best it will do is to fill up your cap with paint. The fluid nozzle tip is actually sticking bairly out of the cap into the air stream where the vacuum of the moving air draws more paint out to atomize.

It might be better to think of the older style siphon feed gun for this example.

I don’t know for sure here, but maybe the tip needs to extend into the exhaust stream slightly like a paint gun.