You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread 1978 Mercury Cyclone. The pig is in the pen.

- Status

- Not open for further replies.

-

Sponsors (?)

Sell them on ebay as smartphone & tablet mounting kits for cars....I found a bag of scotch locks

Anybody need some?

One on the smartphone, two on the tablet and a matching set to stick to the appropriate place on the dash...

I see that the mice are playing in my thread again....

Today Im pissing off drag racers.

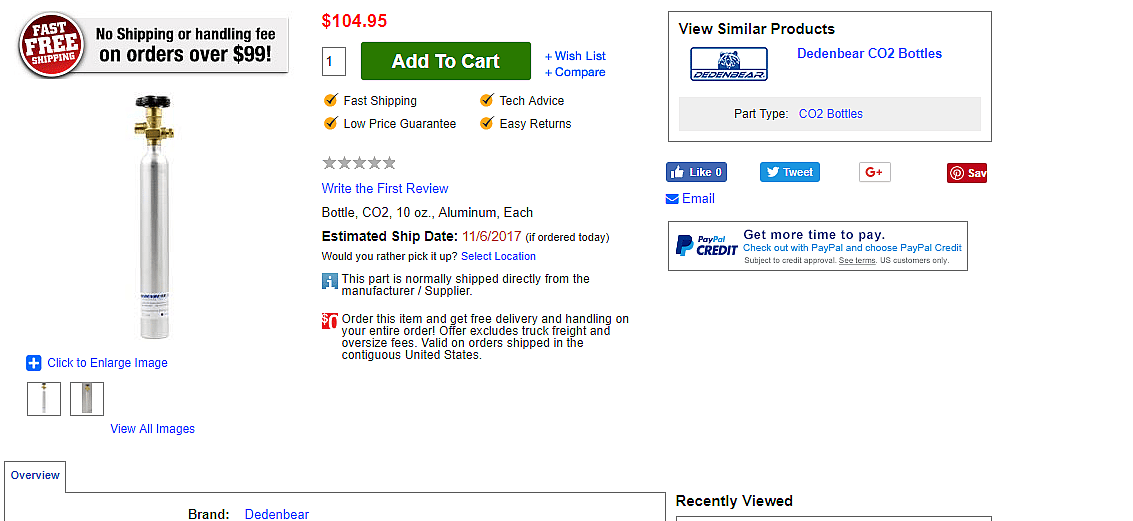

See this thing?

Its a Co2 bottle. Intended for all kinds of pressure activated crap on your average drag car. Stuff like shifters, throttle stops, and just about anything you can think of that could benefit from a shot of high pressure compressed air.

I have two of them. I used them on my orange and black 86 drag car to apply pressure to the dome of my wastegate to allow for sequential increasing boost control back in the days when it was not as easy as it is today. ( That'd be like 2006, when I thought I was gonna be a big time X275 drag radial HU racer)

Last night when I went to the cruise in, I opened my hood when I got there only to find that antifreeze had shot all over the engine. Now that I have the engine getting hot, sometimes there is a temp spike (temp goes to like 220 for a few seconds)

Evidently,...one of my temp spikes got my radiator cap all hot and bothered, and it blew a load of green Jiz all over my intake manifold.

No,....I did not have a catch can... AND No, I didn't even have as much as a piece of rubber hose diverting that possible eruption to the ground.

So I had green jiz on my engine istead.

This morning, I decided to correct that. To fix that meant that I needed a long skinny aluminum bottle.

Something like this:

These things have been banging around in one of my spare tool box drawers for over 10 years now,...it's time I put one of them to good use.

I had to cut the top off, (it was too tall), tap the hole for pipe thread, and drill a drain hole, and a small vent hole on top to allow the thing to accept the overflow should it happen.

Now the bottle looks like this:

Soo much better than before when it was just a "What the hell is that clanking noise?" when I opened that drawer.

Probably coulda sold those things for 50 bucks ea. .. 100 bucks just laying in a drawer for ten years.

At the same time a nice polished tube style overflow catch can probably costs 100 bucks....and I still woulda had to modify the thing to fit where I wanted it to go.

Im saying win.

Its no Listerine bottle, but it'll do.

Well.

I had to put on a day pack, and hike back almost a week to find this thing.

I'm starting the process to convert the valve train over to hydraulic roller if it can be done. Sent off two emails to both Clay Smith, and Schneider cams asking for probability, and possible pricing to regrind the existing honker currently in the engine. I say this, because while listing the specs of the camshaft, I got kind of a shock at just how big the current roller is...

Cam lift on this cam is .315 intake/ .330 exhaust.

Sounds smallish, until you add the 1.75 rocker ratio back in.

.551/.577.

When compared to your standard SBF with an aggressive cam, this is no big deal,...but when considering that this turd in its stock iteration barely lifted the valve....this seems like VasgoJet extreme to me...seems I remember that the spring pressure required to keep the valves closed almost exceeded my machinists ability to check it.

It's no freakin wonder this thing is so loud,....with the valves snapping open and slamming closed like they do.

Changing this over to a hydraulic roller, requires that I also come up w/a re-link-able set of link bar lifters that are currently in the engine. I have Comp Cams working on that now too. The lifters currently in the engine are Comp BBF lifters..

I can just turn them sideways to un link them from each other. Those vertical slotted fasteners are only held on by an Allen headed screw that has been loctited, and peened over on its end to keep it from coming apart. I had to remove one of them when I put the thing together because I could not get one set of lifters to swing out far enough sideways to unlink the bar on one end.

So there's a lock-nutted screw holding one of them together presently.

I asked dude at Comp if they could just sell me a partially finished set of hydraulic lifters w/o the link bars attached, and I'd use the existing link bar set off of my solid versions, and convert the hydraulic set over to this style...

He's checking if they can/will do that, and if both the Endure-x solid and Pro-Magnum hydraulic lifter will allow me to do that if they will.

The springs will have to be changed to a more wussified Spring pressure as well,...id like to be able to do that with the head mounted,..I just don't know how hard it'll be to get that existing spring off considering the pressure.

All in all,..it'll probably be a tick short of a grand if I can do all of this...and the only thing I'll possibly gain is a more quiet valve train that may, or may not be better suited to the turbo.

( I don't know how much better it needs to be, considering the turbo spools at part throttle in this car as it is)

right now the cam is installed at 109.5 as per Schneider cams recommendation over the actual cam grinders.

( which was spec'd at 114 I think).....

I'm also curious to learn whether or not that because of my install point I'm adding to the detonation I'm experiencing because of the increased cylinder pressure as a result.

Hmmmmmm

I had to put on a day pack, and hike back almost a week to find this thing.

I'm starting the process to convert the valve train over to hydraulic roller if it can be done. Sent off two emails to both Clay Smith, and Schneider cams asking for probability, and possible pricing to regrind the existing honker currently in the engine. I say this, because while listing the specs of the camshaft, I got kind of a shock at just how big the current roller is...

Cam lift on this cam is .315 intake/ .330 exhaust.

Sounds smallish, until you add the 1.75 rocker ratio back in.

.551/.577.

When compared to your standard SBF with an aggressive cam, this is no big deal,...but when considering that this turd in its stock iteration barely lifted the valve....this seems like VasgoJet extreme to me...seems I remember that the spring pressure required to keep the valves closed almost exceeded my machinists ability to check it.

It's no freakin wonder this thing is so loud,....with the valves snapping open and slamming closed like they do.

Changing this over to a hydraulic roller, requires that I also come up w/a re-link-able set of link bar lifters that are currently in the engine. I have Comp Cams working on that now too. The lifters currently in the engine are Comp BBF lifters..

I can just turn them sideways to un link them from each other. Those vertical slotted fasteners are only held on by an Allen headed screw that has been loctited, and peened over on its end to keep it from coming apart. I had to remove one of them when I put the thing together because I could not get one set of lifters to swing out far enough sideways to unlink the bar on one end.

So there's a lock-nutted screw holding one of them together presently.

I asked dude at Comp if they could just sell me a partially finished set of hydraulic lifters w/o the link bars attached, and I'd use the existing link bar set off of my solid versions, and convert the hydraulic set over to this style...

He's checking if they can/will do that, and if both the Endure-x solid and Pro-Magnum hydraulic lifter will allow me to do that if they will.

The springs will have to be changed to a more wussified Spring pressure as well,...id like to be able to do that with the head mounted,..I just don't know how hard it'll be to get that existing spring off considering the pressure.

All in all,..it'll probably be a tick short of a grand if I can do all of this...and the only thing I'll possibly gain is a more quiet valve train that may, or may not be better suited to the turbo.

( I don't know how much better it needs to be, considering the turbo spools at part throttle in this car as it is)

right now the cam is installed at 109.5 as per Schneider cams recommendation over the actual cam grinders.

( which was spec'd at 114 I think).....

I'm also curious to learn whether or not that because of my install point I'm adding to the detonation I'm experiencing because of the increased cylinder pressure as a result.

Hmmmmmm

I would definitely investigate if reinstalling it at 114 will bleed off so cylinder pressure. If you're getting it reground, may be a bit more overlap to help in the bleeding off cylinder pressure dept. I seem to remember you saying the head isn't coming off, but if it does, maybe a bit thicker head gasket to lower the static CR too.

And while you're at it, the damn machine guns.....mount them already!

And while you're at it, the damn machine guns.....mount them already!

Seems the valve train noise elimination is worth it alone, given you were talking about it being a nuisance of sorts, and you planned to insulate the car to help cut the noise down... As far as the rest of that cam voodoo talk, good work, nice job, keep it up!

Spoke with all parties that would be involved. The lifters are a potential problem. Nobody makes a lifter to give me what I need w/o custom dollars entering the picture. But,....I can have the existing solid roller ramps ground less aggressively, and that would significantly reduce my noise issue while still allowing me to keep the existing solid valvetrain. I’d be able to change the valve springs to lessen the spring pressure as a result, and get some potential durability too. I may even be able to get a better cam profile to take better advantage of the turbo to top it all off.

So,....springs, a regrind, and a head gasket,..and a bunch of labor on my part....less than half of what I originally expected.

But that’s all dependent on me not deciding on pushing those pistons out of their holes once that head is off, and putting new rings on them too.

And I can just about guarantee how that’ll go.....

So,....springs, a regrind, and a head gasket,..and a bunch of labor on my part....less than half of what I originally expected.

But that’s all dependent on me not deciding on pushing those pistons out of their holes once that head is off, and putting new rings on them too.

And I can just about guarantee how that’ll go.....

Hate to say it Mike, but since you're there......Spoke with all parties that would be involved. The lifters are a potential problem. Nobody makes a lifter to give me what I need w/o custom dollars entering the picture. But,....I can have the existing solid roller ramps ground less aggressively, and that would significantly reduce my noise issue while still allowing me to keep the existing solid valvetrain. I’d be able to change the valve springs to lessen the spring pressure as a result, and get some potential durability too. I may even be able to get a better cam profile to take better advantage of the turbo to top it all off.

So,....springs, a regrind, and a head gasket,..and a bunch of labor on my part....less than half of what I originally expected.

But that’s all dependent on me not deciding on pushing those pistons out of their holes once that head is off, and putting new rings on them too.

And I can just about guarantee how that’ll go.....

When would you be that close again otherwise?

From my limited experience with cams (disclaimer), I don't think lift has much to do with the cam's noise level. The way I understand it, lift should be directly linked to a heads ability to flow at that lift. Duration has to do more with rpm range and timing of said events determines how fast and slow the valves open and close.

I know....thats a lot of generalizations there.

My point is, I would be less concerned about the actual lift and more concerned about timing events and the aggressiveness of the lobes. I would think that is where the noise is coming from.

I agree that the installation of the cam could be suspect if it was degrees differently than the grinder specified.

Either way, good luck with it.

Joe

I know....thats a lot of generalizations there.

My point is, I would be less concerned about the actual lift and more concerned about timing events and the aggressiveness of the lobes. I would think that is where the noise is coming from.

I agree that the installation of the cam could be suspect if it was degrees differently than the grinder specified.

Either way, good luck with it.

Joe

I hear ya...I know that if that head is off, and the cylinders look alright, the pistons will come out....It's all part of the process of "steeling myself" to face impending reality.Hate to say it Mike, but since you're there......

When would you be that close again otherwise?

You need to drop a couple of letters raggedy...I think you would regret not swapping the springs while you had it apart.

Its not the Sp rings Ill be considering replacing if the head is off,....it'll be the Rings.

I know its the straight up solid roller cam ramps that are responsible for the valve train clatter Joe,....I was just rambling to make a point that the cam is big (lift wise) for an I-6...From my limited experience with cams (disclaimer), I don't think lift has much to do with the cam's noise level. The way I understand it, lift should be directly linked to a heads ability to flow at that lift. Duration has to do more with rpm range and timing of said events determines how fast and slow the valves open and close.

I know....thats a lot of generalizations there.

My point is, I would be less concerned about the actual lift and more concerned about timing events and the aggressiveness of the lobes. I would think that is where the noise is coming from.

I agree that the installation of the cam could be suspect if it was degrees differently than the grinder specified.

Either way, good luck with it.

Joe

If they change the ramp, then the valve will not open as quickly, nor stay open as long...

It's that snapping open and slamming closed why my junk is so noisy...

I told the wife (who could personally give a rat's red bunion hole) that the thing was so loud..

She said "I hope you aren't doing this for me."

I said I wasn't....

She said "Then why're you doing it?"

Uhhhhhhhh......Because?

Yeah- I thought rings when I typed it..I’d swear I typed rings.. and until you pointed it out-I thought I had written ringsYou need to drop a couple of letters raggedy...

Its not the Sp rings Ill be considering replacing if the head is off,....it'll be the Rings.

I know its the straight up solid roller cam ramps that are responsible for the valve train clatter Joe,....I was just rambling to make a point that the cam is big (lift wise) for an I-6...

If they change the ramp, then the valve will not open as quickly, nor stay open as long...

It's that snapping open and slamming closed why my junk is so noisy...

I told the wife (who could personally give a rat's red bunion hole) that the thing was so loud..

She said "I hope you aren't doing this for me."

I said I wasn't....

She said "Then why're you doing it?"

Uhhhhhhhh......Because?

Do you know anything about the flow for that head? Does it actually flow well at those lifts? If it does, hopefully it can be reground without sacrificing too much of the lift.

Joe

Uhhhhhhhh......Because less wear on the valvetrain limiting the chance of premature failure?

I told myself that I wasn't gonna drive this thing again until I get the water meth kit installed. Right now, that'll mean that the car will sit until Nov 21, which is my actual 60th b day...

*sigh....

*sigh....

If it makes you feel better, there will probably be snow on the ground before my car is road worthy, which means I wont drive it until April...

UH OH, the project has gotten to the WEP (wife explanation point), which in my previous experience usually leads to less than optimal ROI. Unless the project is new flooring, furniture or something not at all related to your hot rod.

I believe that most modern grinders have a tight lash solid roller profile. I think those are in the neighborhood of only .010-..012 hot lash. I'm old school, so that seems really tight, but then again, I doubt your tractor engine is going to see the high side of 5k rpm, let alone 7500.

I believe that most modern grinders have a tight lash solid roller profile. I think those are in the neighborhood of only .010-..012 hot lash. I'm old school, so that seems really tight, but then again, I doubt your tractor engine is going to see the high side of 5k rpm, let alone 7500.

- Status

- Not open for further replies.