Code 23 - Throttle sensor out of range or throttle set too high - TPS needs to be reset to below 1.2 volts at idle. Keep in mind that when you turn the idle screw to set the idle speed, you change the TPS setting.

You'll need a Digital Voltmeter (DVM) to do the job.

Wire colors & functions:

Orange/white = 5 volt VREF from the computer

Dark Green/lt green = TPS output to computer

Black/white = Signal ground from computer

Always use the Dark Green/lt green & Black/white wires to set the TPS base voltage.

Do the test with the ignition switch in the Run position without the engine running.

Use the Orange/white & Black white wires to verify the TPS has the correct 5 volts source from the computer.

When you installed the sensor make sure you place it on the peg right and then tighten it down properly. Loosen the back screw a tiny bit so the sensor can pivot and loosen the front screw enough so you can move it just a little in very small increments. I wouldn’t try to adjust it using marks. Set it at .6.v-.9 v.

1. Always adjust the TPS and Idle with the engine at operating temp. Dive it around for a bit if you can and get it nice and warm.

2. When you probe the leads of the TPS, do not use an engine ground, put the ground probe into the lead of the TPS. You should be connecting both meter probes to the TPS and not one to the TPS and the other to ground.

If setting the TPS doesn’t fix the problem, then you may have wiring problems.

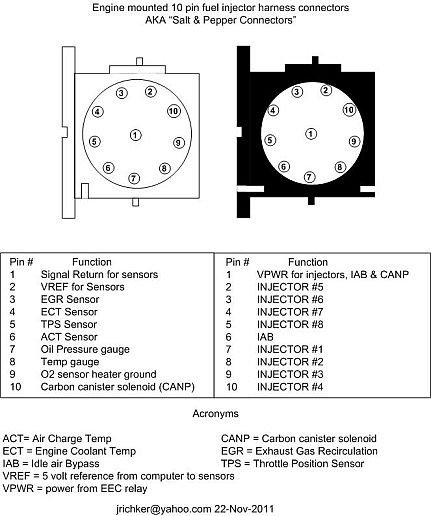

With the power off, measure the resistance between the black/white wire and battery ground. You should see less than 2 ohms. Check the same black /white wire on the TPS and MAP/Baro sensor. More than 1 ohm there and the wire is probably broken in the harness between the engine and the computer. The 10 pin connectors pass the black/white wire back to the computer, and can cause problems.

See the following website for some help from Tmoss (diagram designer) & Stang&2Birds (website host)

http://www.veryuseful.com/mustang/tech/engine/images/88-91eecPinout.gif

See the graphic for the 10 pin connector circuit layout.

Code 29 - Vehicle Speed Sensor (VSS) is an electronic sender mounted on the speedo pickup gear on the trans. It works the cruse control for both 5 speed and auto trans cars. The VSS is used to tell the computer to speed up the idle as you slow to a stop. This helps keep the engine from stalling when you slow down for a stop sign or stop light.

Check to see if the electrical connector is plugged into it. Clean the connector & contacts with non flammable brake parts cleaner prior to replacing the sensor, as that may fix the problem. The sensor cost is under $30 and it is easy to replace.

Code 67

Revised 18-Mar-2017 to include warning about the necessity of having a 5 speed O2 Sensor wiring harness when bypassing the wiring for test purposes

Cause of problem:

Clutch not depressed (5 speed) or car not in neutral (5 speed and auto) or not in park (auto) or A/C in On position when codes where dumped. Possible neutral safety switch or wiring problem. This code will prevent you from running the Key On Engine On tests.

External evidence from other sources claims that a code 67 can cause an idle surge condition. Do try to find and fix any issues with the switch and wiring if you get a code 67.

What the NSS (Neutral Safety Switch) does:

5 speed transmission: It has no connection with the starter, and the engine can be cranked without it being connected.

Auto transmission: It is the safety interlock that prevents the starter from cranking the engine with the transmission in gear.

What it does for both 5 speed and auto transmission cars:

The computer wants to make sure the A/C is off due to the added load on the engine for the engine running computer diagnostic tests. It also checks to see that the transmission is in Neutral (5 speed and auto transmission) and the clutch depressed (T5, T56, Tremec 3550 & TKO)). This prevents the diagnostics from being run when the car is driven. Key On Engine Running test mode takes the throttle control away from the driver for several tests.

This could prove hazardous if the computer was jumpered into test mode and then driven.

The following is for 5 speed cars only. Do not do this unless you are sure that you have a 5 speed O2 Sensor harness!!!! Smoke, sparks and expensive pain in the wallet may ensue if you don’t.

The NSS code 67 can be bypassed for testing. You will need to temporarily ground computer pin 30 to the chassis. Computer pin 30 uses a Lt blue/yellow wire. Remove the passenger side kick panel and then remove the plastic cover from the computer wiring connector. Use a safety pin to probe the connector from the rear. Jumper the safety pin to the ground near the computer.

Be sure to remove the jumper BEFORE attempting to drive the car!!!

Code 81 – Secondary Air Injection Diverter Solenoid failure AM2. The solenoid valve located on the back side of the passenger side wheel well is not functional. Possible bad wiring, bad connections, missing or defective solenoid valve. Check the solenoid valve for +12 volts at the Red wire and look for the Lt Green/Black wire to switch from +12 volts to 1 volt or less. The computer controls the valve by providing a ground path on the LT Green/Black wire for the solenoid valve.

With the with the ignition on, look for 12 volts on the red wire on the solenoid connector. No 12 volts and you have wiring problems.

With the engine running, stick a safety pin in the LT Green/Black wire for the solenoid valve & ground it. That should turn the solenoid on and cause air to flow out the port that goes to the pipe connected to the cats. If it doesn't, the valve is bad. If it does cause the airflow to switch, the computer or wiring going to the computer is not signaling the solenoid valve to open.

Putting the computer into self test mode will cause the solenoid valve to toggle. If you listen carefully, you may hear it change states.

Code 82 – Secondary Air Injection Diverter Solenoid failure AM1. Possible bad wiring, bad connections, missing or defective solenoid valve. Check the solenoid valve for +12 volts at the Red wire and look for the Red/White wire to switch from +12 volts to 1 volt or less. The computer controls the valve by providing a ground path on the Red/White wire for the solenoid valve

With the engine running, stick a safety pin in the Red/White wire for the solenoid valve & ground it. That should turn the solenoid on and cause air to flow out the port that goes to the pipe connected to the heads. If it doesn't, the valve is bad. If it does cause the airflow to switch, the computer or wiring going to the computer is not signaling the solenoid valve to open.

Both 81 & 82 codes usually mean that some uneducated person removed the solenoid control valves for the Thermactor Air system in an attempt to make the car faster. It doesn't work that way: no working control valves can cause the cat converters to choke and clog. If you do not have cat converters on the car, you can ignore the 81 & 82 codes.