1990 Mustang GT - Supercharged - Kenne Bell

Okay been having this problem for a while ... cannot drive car. Start it up and it cuts off like IAC problem but my main concern is the Code 91 I am continually getting. Was getting Code 91 (every test), Code 12 (every test), Code 13 (before ... raised idle and it went away), Code 18 (every now and then). I think the main problem is the Code 91 because when it goes thru the KOER Test, you can hear that it is running bad and cannot adjust the engine speed properly due to the lean condition. Then, the smell of raw gas is just overwhelming.

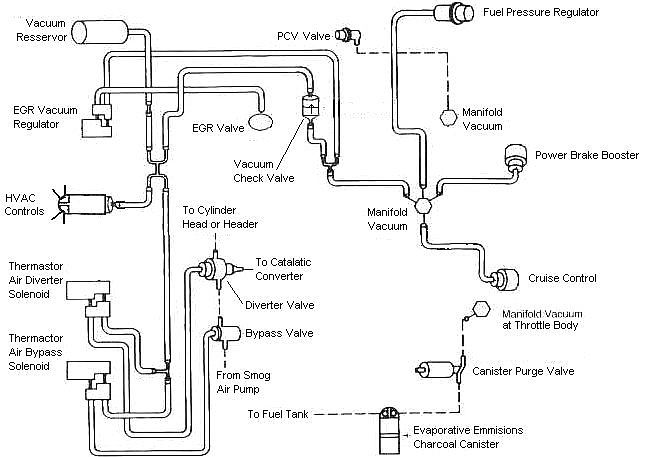

I blocked off EGR to take that out of the equation. Checked Thermactor system everything works. Still get codes with Thermactor system disconnected which would serve to lean it even more. Replaced upper intake gasket to no avail. Replaced oxygen sensors and even switched them from side to side to no avail. Tested drivers side oxygen sensor and found heater receiving 12 volts and that the resistence was within specs. Haven't checked for shorts to ground or opens yet though. Performed a Balance test but always get a Code 9. Looked in my EEC IV book written by Charles Probst on Page 227 .... he states that a Balance test will not identify a lean nor non-firing injector ... how can this be??? Doesn't the decrease in RPM still point to that cylinder since it is not contributing to the overall RPM? I don't understand anyone that does please explain why a lean injector or non working injector wouldn't show up???

All of my plugs look kinda of lean. Number 6 cylinder had a yellowish-orange center porcolean color so I put in one from another set but do not understand why it was discolored. Had some rust on outside between metal and porcolean that could have run between tot he porcolean and metal to the inner porcolean ... dont' know. I also ran the engine when it was stumbling terribly and removed the fuel regulator hose and it ran a bit better but not by much so it does seem like a lean condition. It is most evident at idle and off-idle just completely terrible running. One time, I ran it at 2000 RPM for the Cylinder Balance test and the headers were glowing orange so I am concerned about running this car too much with this condition. The computer is definitely over-compensating ... wouldn't that tell me that the oxygen sensors ARE IN FACT WORKING?

Spoke to a guy at Kenne Bell who suggested replacing upper intake manifold gasket. Did it but no change. He stated then changing the lower but stated that unless the heads have been planed or with a different intake they should not pose a problem. Mine are stock and it was changed years ago and sealed to the best of my ability. Have not done a compression test yet especially on drivers side. Did one a year ago ... everything looked good but cylinder #6 was a bit low but still within 10% of the others. Guess what I'm saying, this wild-goose chase is beating me up!!!

Checked injectors with stethoscope and they all appear to be working. Can't do anything more with them since they are all under the supercharger. They are however new ACCel units replaced last year. I am so tired of trying to find tests to uncover what this problem is but have to get it fixed!!! And, every test takes so long or I can't get to something or it takes all day and is inconclusive. Thus, anyone have some diagnostic ideas I haven't already tried in defining what this lean condition is and how to solve it??? I do not want to keep going into the engine and not finding things and wasting a lot of time, money and stressing me out! Between this crappy OBD I system and faulty autoparts store parts, I do not relish working on cars anymore (hobby for 25 years or more) because someone else fools you with something crappy to steal the dollars out of your pocket. I have been dealing with a major parts reliability problem for the last three years because everyone is buying overseas and charging regular prices to line their pockets ... no part replaced can be considered or eliminated ... just driving me crazy!!!

Any help would be appreciated ... I shall try anything as time allows to get this solved but would like to do it methodically and w/o tearing everything apart! Thank You!

Okay been having this problem for a while ... cannot drive car. Start it up and it cuts off like IAC problem but my main concern is the Code 91 I am continually getting. Was getting Code 91 (every test), Code 12 (every test), Code 13 (before ... raised idle and it went away), Code 18 (every now and then). I think the main problem is the Code 91 because when it goes thru the KOER Test, you can hear that it is running bad and cannot adjust the engine speed properly due to the lean condition. Then, the smell of raw gas is just overwhelming.

I blocked off EGR to take that out of the equation. Checked Thermactor system everything works. Still get codes with Thermactor system disconnected which would serve to lean it even more. Replaced upper intake gasket to no avail. Replaced oxygen sensors and even switched them from side to side to no avail. Tested drivers side oxygen sensor and found heater receiving 12 volts and that the resistence was within specs. Haven't checked for shorts to ground or opens yet though. Performed a Balance test but always get a Code 9. Looked in my EEC IV book written by Charles Probst on Page 227 .... he states that a Balance test will not identify a lean nor non-firing injector ... how can this be??? Doesn't the decrease in RPM still point to that cylinder since it is not contributing to the overall RPM? I don't understand anyone that does please explain why a lean injector or non working injector wouldn't show up???

All of my plugs look kinda of lean. Number 6 cylinder had a yellowish-orange center porcolean color so I put in one from another set but do not understand why it was discolored. Had some rust on outside between metal and porcolean that could have run between tot he porcolean and metal to the inner porcolean ... dont' know. I also ran the engine when it was stumbling terribly and removed the fuel regulator hose and it ran a bit better but not by much so it does seem like a lean condition. It is most evident at idle and off-idle just completely terrible running. One time, I ran it at 2000 RPM for the Cylinder Balance test and the headers were glowing orange so I am concerned about running this car too much with this condition. The computer is definitely over-compensating ... wouldn't that tell me that the oxygen sensors ARE IN FACT WORKING?

Spoke to a guy at Kenne Bell who suggested replacing upper intake manifold gasket. Did it but no change. He stated then changing the lower but stated that unless the heads have been planed or with a different intake they should not pose a problem. Mine are stock and it was changed years ago and sealed to the best of my ability. Have not done a compression test yet especially on drivers side. Did one a year ago ... everything looked good but cylinder #6 was a bit low but still within 10% of the others. Guess what I'm saying, this wild-goose chase is beating me up!!!

Checked injectors with stethoscope and they all appear to be working. Can't do anything more with them since they are all under the supercharger. They are however new ACCel units replaced last year. I am so tired of trying to find tests to uncover what this problem is but have to get it fixed!!! And, every test takes so long or I can't get to something or it takes all day and is inconclusive. Thus, anyone have some diagnostic ideas I haven't already tried in defining what this lean condition is and how to solve it??? I do not want to keep going into the engine and not finding things and wasting a lot of time, money and stressing me out! Between this crappy OBD I system and faulty autoparts store parts, I do not relish working on cars anymore (hobby for 25 years or more) because someone else fools you with something crappy to steal the dollars out of your pocket. I have been dealing with a major parts reliability problem for the last three years because everyone is buying overseas and charging regular prices to line their pockets ... no part replaced can be considered or eliminated ... just driving me crazy!!!

Any help would be appreciated ... I shall try anything as time allows to get this solved but would like to do it methodically and w/o tearing everything apart! Thank You!