You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread Want To Blow 5 Years And $50k On A Foxbody? Step By Step Instructions Inside!

- Thread starter RacEoHolic330

- Start date

-

Sponsors (?)

Stop eating popcorn before dinner. Scott's cooking steak and peas.

But I just had lunch!

Edit** Actually I skipped lunch today. We got a different cook on board who likes to preserve things in salt before serving.

Preserved in salt?....Are you on the Mayflower?But I just had lunch!

Edit** Actually I skipped lunch today. We got a different cook on board who likes to preserve things in salt before serving.

Preserved in salt?....Are you on the Mayflower?

No, they had beer on board

I think they also had Scurvy and Dysentery too.No, they had beer on board

stprorolla49

Active Member

Scott, for some odd reason, I made my way over to the 5.0 section and stumbled on this thread! It's been WAY too long man, I didn't realize you were tearing this thing down to the shell! Your fab work on the turbo piping looks impressive, I am very jealous of this build. I will definitely be watching this!

1989GtFoxBody

Member

Somebody's distracting Scott from making progress, (and it ain't me or pea talk).Enough about your peas Mike, your distracting Scott from making progress!

No real updates at the moment. Been busy lately with a bunch of other stuff going on. Working longer hours and I just bought a handgun, so I've been at the range playing with that. I ran out of ammo, so now I guess I can get back to working on the car!

It's has been quite some time Mike. Hope you're doing well over there in 4.6 land! If you ever find yourself in PA, let me know and we can hang.

Scott, for some odd reason, I made my way over to the 5.0 section and stumbled on this thread! It's been WAY too long man, I didn't realize you were tearing this thing down to the shell! Your fab work on the turbo piping looks impressive, I am very jealous of this build. I will definitely be watching this!

It's has been quite some time Mike. Hope you're doing well over there in 4.6 land! If you ever find yourself in PA, let me know and we can hang.

So I should have some time Thursday and Friday night to work on the car. I'm seriously starting to fall behind on things and it's stressing me out. I'm hoping I can get everything done that I need to so I can get the engine pulled back out.

List of things to do with engine still in:

-Box in frame rail/fender apron around turbo

-Install oil dran line

-Redo the hole for the discharge tube

-Install lower radiator support and check fan clearances

-Drill holes for catch can mount on firewall

-Mark holes in firewall for engine harness (everything will come into the engine bay from the transmission tunnel area)

Anything else I should do or mock up before I yank the engine? I feel like I'm forgetting something. Once it's out, it's not going back in until the shell has been painted.

List of things to do with engine still in:

-Box in frame rail/fender apron around turbo

-Install oil dran line

-Redo the hole for the discharge tube

-Install lower radiator support and check fan clearances

-Drill holes for catch can mount on firewall

-Mark holes in firewall for engine harness (everything will come into the engine bay from the transmission tunnel area)

Anything else I should do or mock up before I yank the engine? I feel like I'm forgetting something. Once it's out, it's not going back in until the shell has been painted.

So I should have some time Thursday and Friday night to work on the car. I'm seriously starting to fall behind on things and it's stressing me out. I'm hoping I can get everything done that I need to so I can get the engine pulled back out.

List of things to do with engine still in:

-Box in frame rail/fender apron around turbo

-Install oil dran line

-Redo the hole for the discharge tube

-Install lower radiator support and check fan clearances

-Drill holes for catch can mount on firewall

-Mark holes in firewall for engine harness (everything will come into the engine bay from the transmission tunnel area)

Anything else I should do or mock up before I yank the engine? I feel like I'm forgetting something. Once it's out, it's not going back in until the shell has been painted.

Wait,....You have a schedule? Every time I tried to have a plan, I ended up staggering out of the garage w/ a black face and grinding dust filled nasal cavities, w/ only one item on the list complete.

Cool out. There'll be days when everything goes right. If you don't have a list,.....you feel like you get so much more done.

And....I think after you get done w/ your list,...It'd be safe to move on to paint.

I don't have an actual schedule. I'm not that anal. I do, however, have general milestones that I'd like to be at. I was hoping to have the underside of the car all ready to paint by now with the warm weather finally here.

In the end, as long as the car is done for the Ford Nationals at Carlisle next May, I'll be happy.

In the end, as long as the car is done for the Ford Nationals at Carlisle next May, I'll be happy.

Progress at last!

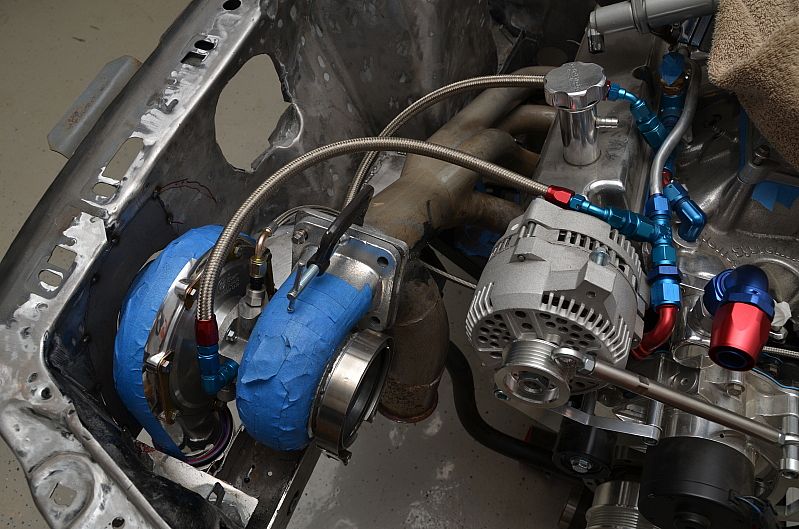

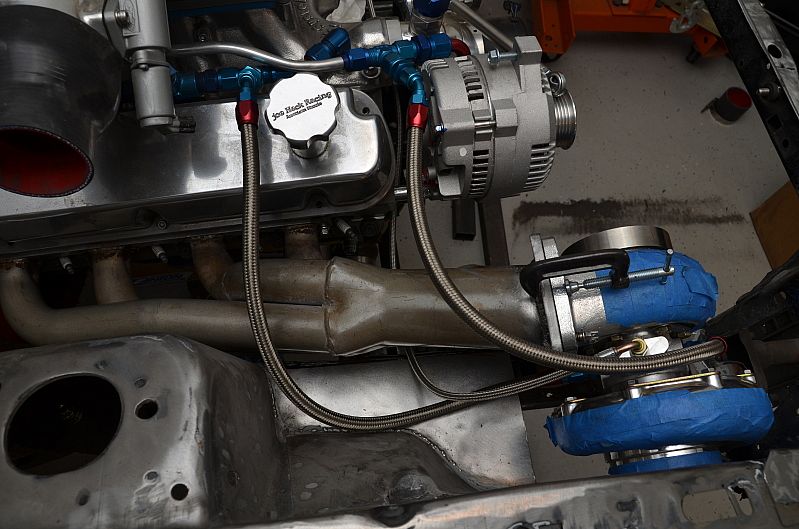

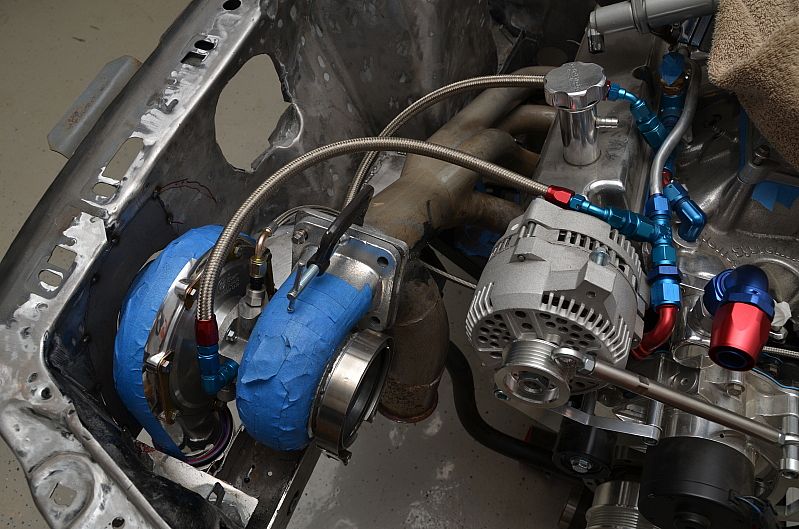

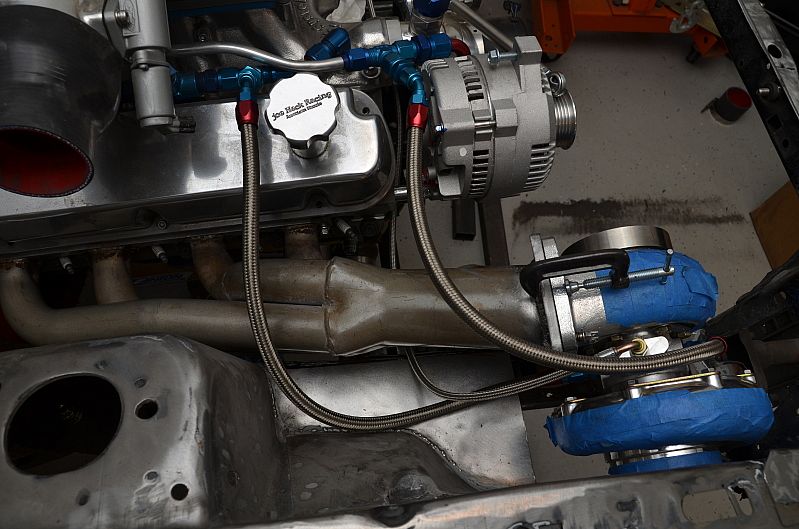

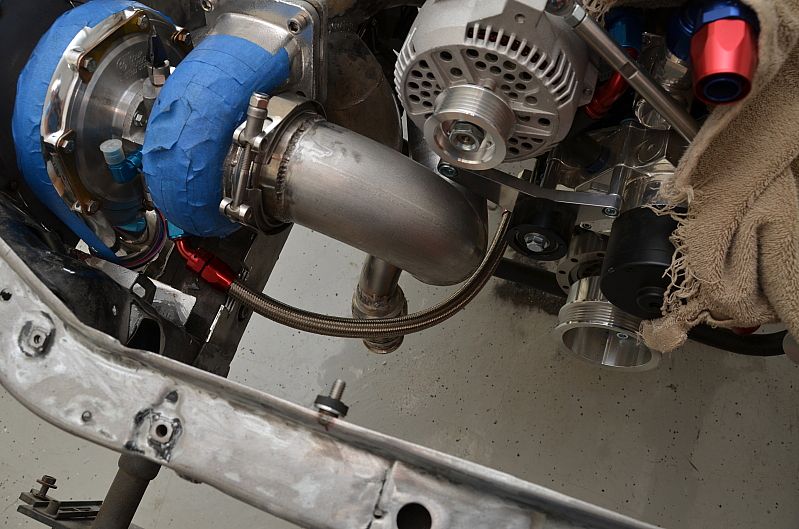

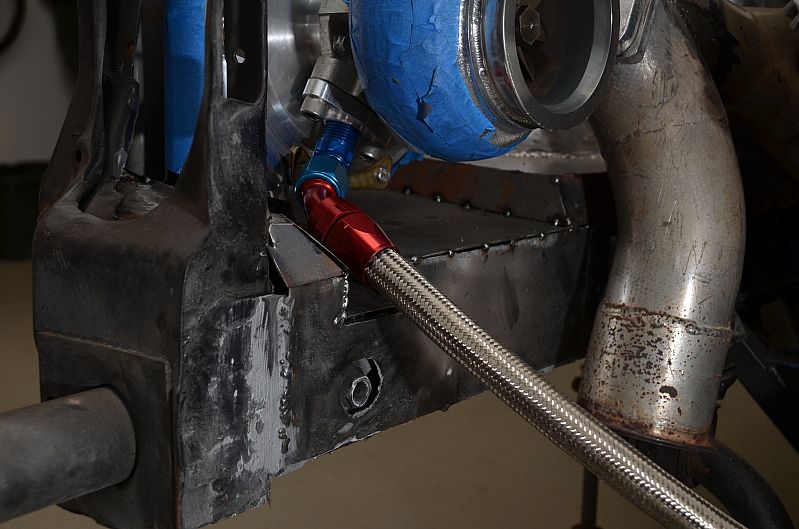

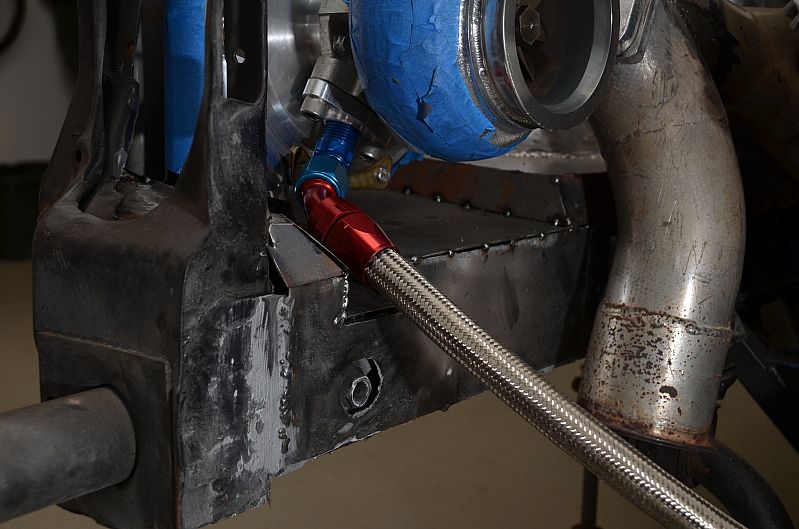

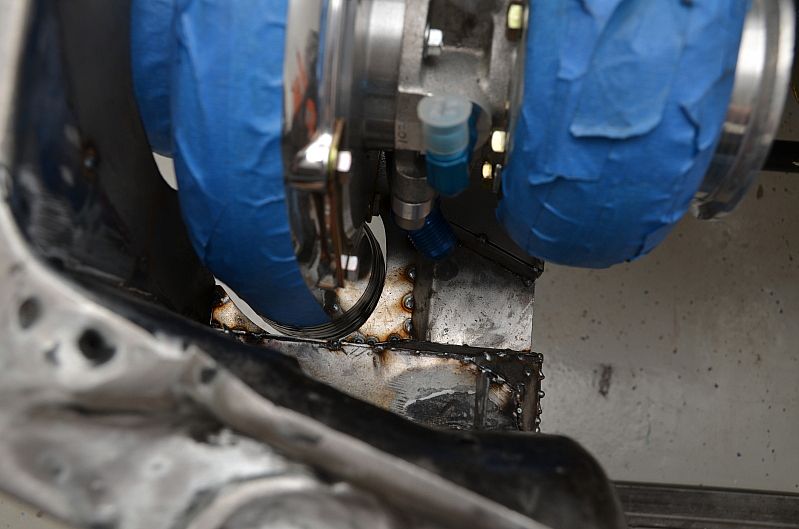

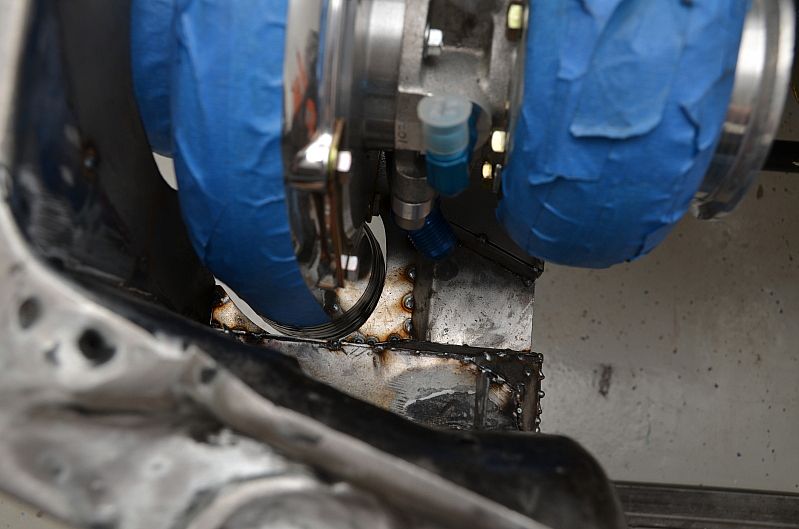

I installed the braided lines for the water and oil feeds/returns. Here are the water lines all done:

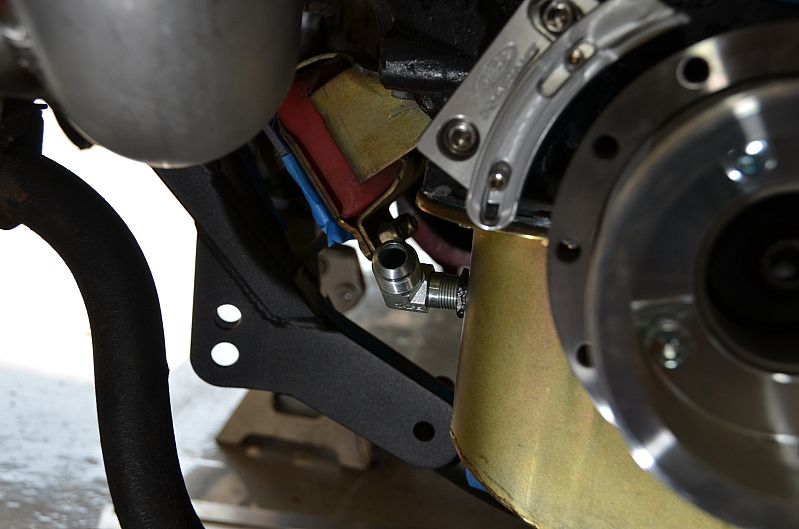

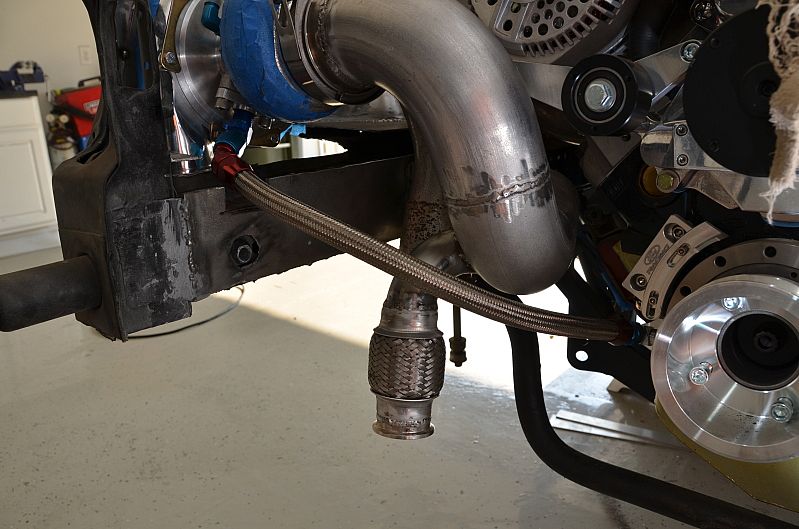

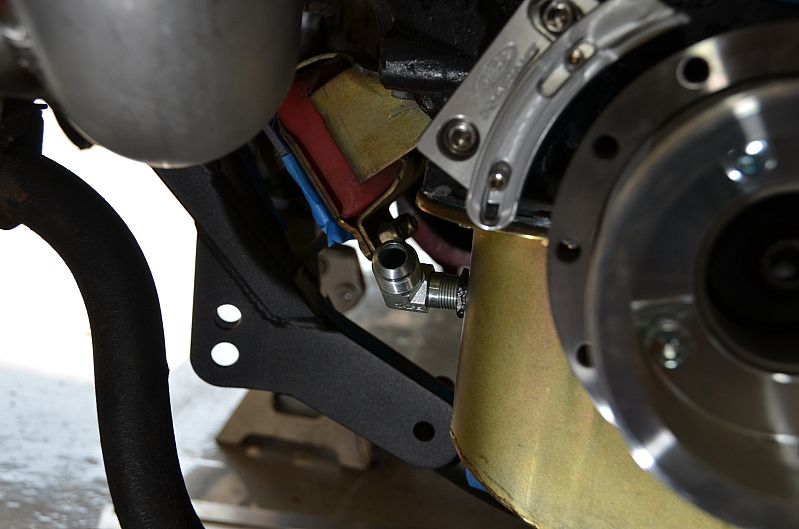

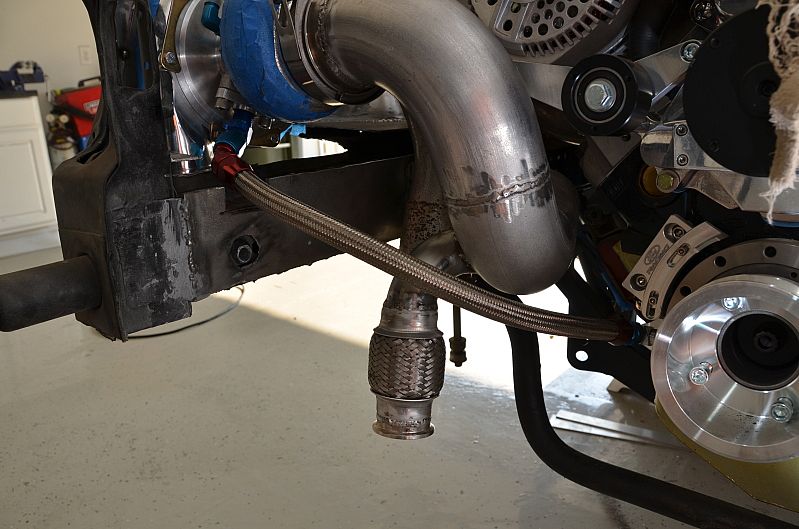

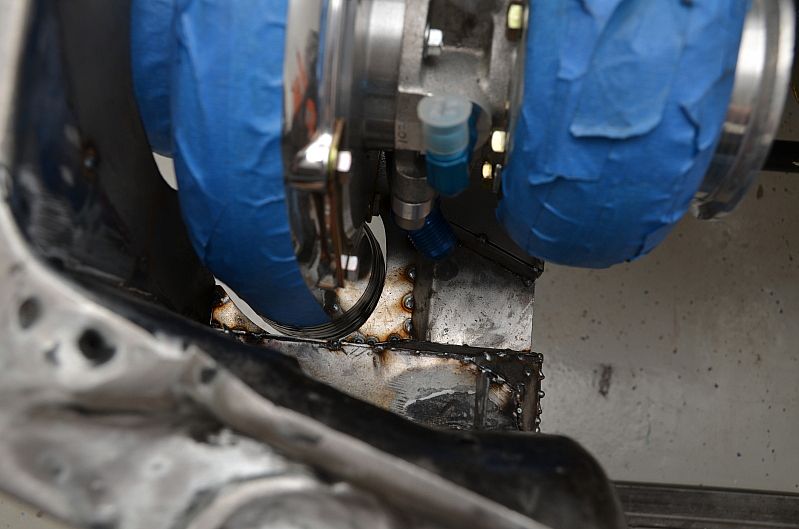

I figured out a combination of AN fittings that would allow me to more easily install the oil drain. I had to notch the frame rail for the fitting to have the right pitch.

90 degree fitting out of the pan:

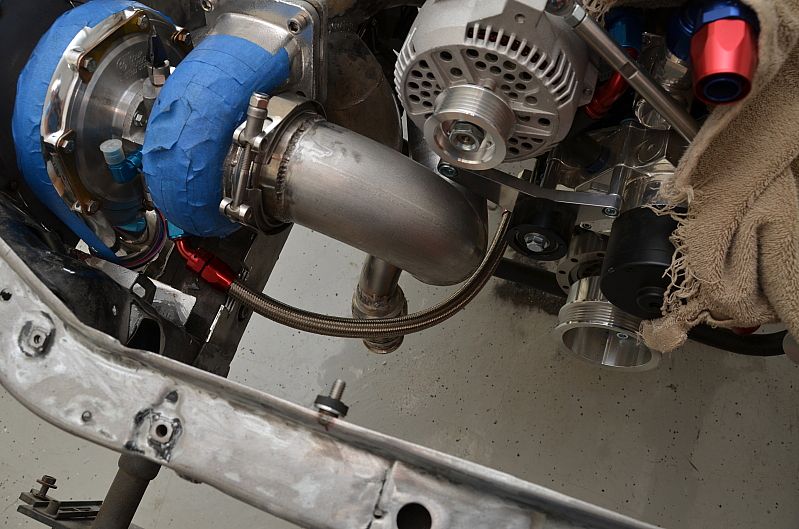

Line installed:

For those that are curious, here are the tools I use to assemble the AN fittings. Adjustable aluminum wrench and aluminum vice inserts. Works really well.

I boxed in just about all the the frame rail as well. Pictures to follow, need to upload them...

I installed the braided lines for the water and oil feeds/returns. Here are the water lines all done:

I figured out a combination of AN fittings that would allow me to more easily install the oil drain. I had to notch the frame rail for the fitting to have the right pitch.

90 degree fitting out of the pan:

Line installed:

For those that are curious, here are the tools I use to assemble the AN fittings. Adjustable aluminum wrench and aluminum vice inserts. Works really well.

I boxed in just about all the the frame rail as well. Pictures to follow, need to upload them...

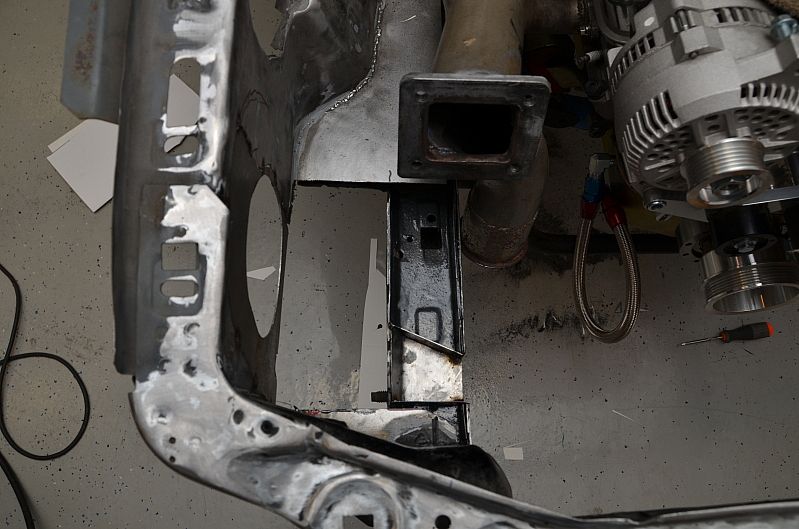

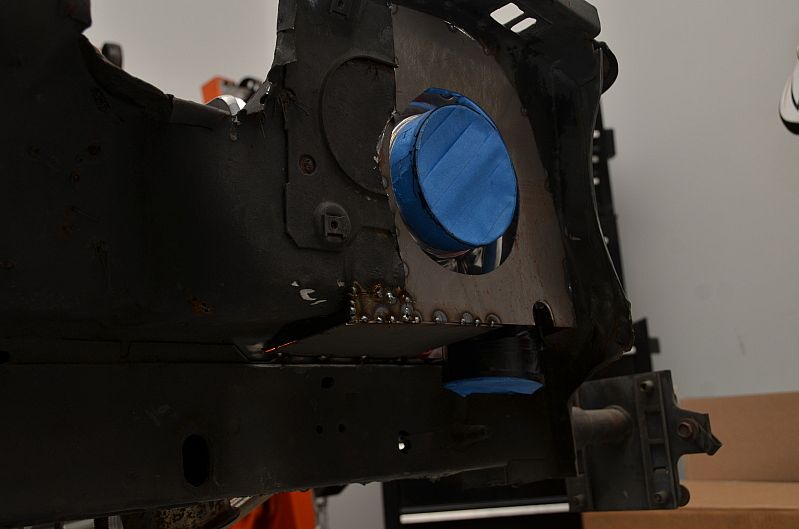

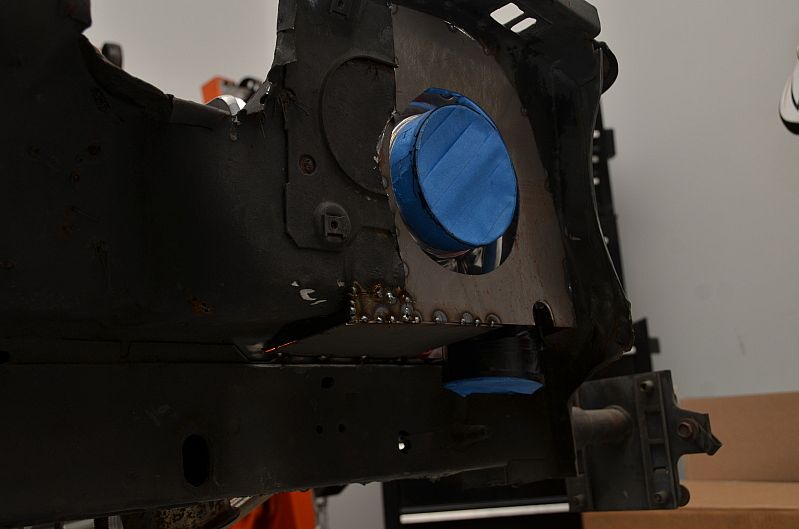

Just to recap, here's the mess I had to make of the inner fender apron to get the turbo to fit:

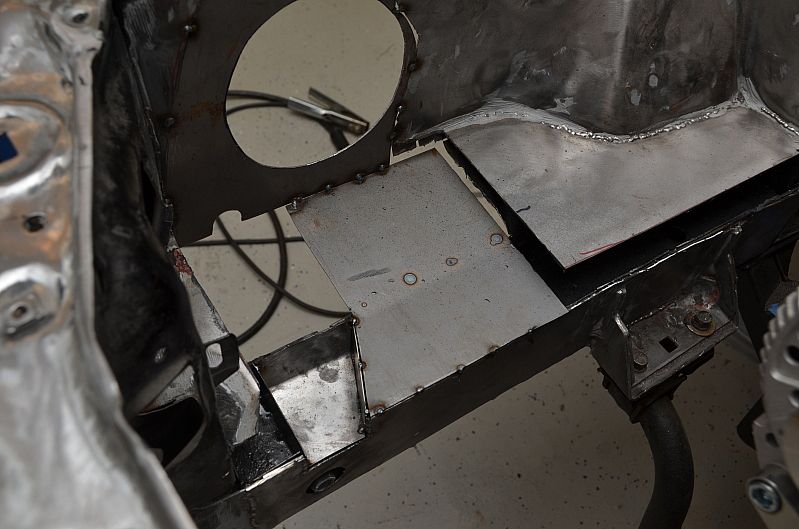

So, the solution was to box in as much as I possibly could to make everything look better and a little less butchered. Took a lot of paper templates and metal trimming to get it done.

Used a cordless jig saw to cut a 5" hole for the compressor inlet

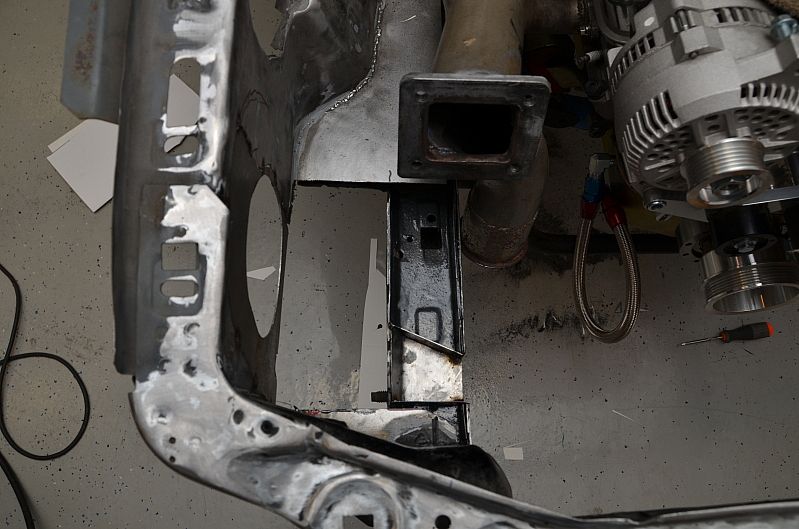

Cut pieces for the boxed out area around the drain fitting:

Cut more and more pieces to box the rest of the framerail in:

Just as I was welding in my second to last piece, I ran out of welding wire

I still need to weld in that missing piece and I also want to weld in some radiused pieces around the outlet to eliminate the round peg in a square hold look. Everything fits pretty well though if you ask me!

I'll finish up the welds and grid everything smooth and pretty once the engine is out. No point in doing it while it's still in there.

So, the solution was to box in as much as I possibly could to make everything look better and a little less butchered. Took a lot of paper templates and metal trimming to get it done.

Used a cordless jig saw to cut a 5" hole for the compressor inlet

Cut pieces for the boxed out area around the drain fitting:

Cut more and more pieces to box the rest of the framerail in:

Just as I was welding in my second to last piece, I ran out of welding wire

I still need to weld in that missing piece and I also want to weld in some radiused pieces around the outlet to eliminate the round peg in a square hold look. Everything fits pretty well though if you ask me!

I'll finish up the welds and grid everything smooth and pretty once the engine is out. No point in doing it while it's still in there.

Who asked?Just to recap, here's the mess I had to make of the inner fender apron to get the turbo to fit:

.Everything fits pretty well though if you ask me!

Man I tell ya, you are a cutting and welding fool. Everything you've done looks really good. It is really refreshing to look at something that's not just hacked in there.

So many cars down here are done so down and dirty, that that hole you started w/ is usually left that way, w/a 1-3 gal nitrous enrichment fuel cell hanging out of it. I gave up asking people why they left it looking like sh it after getting told that pretty doesn't make it go faster.

"That's OK bubba, fast doesn't make it any less of a hack.

Good Job sir.

Thanks Mike. Much appreciated. My days of hacking things are well behind me. The whole car is still in a very crude fabrication stage right now, so I'm excited to get it all cleaned up and ready for paint. I want this car to start looking like an actual restoration project and not a repo case.

I enjoyed fabricating these pieces more so than the hotside parts mainly because I didn't need to use the grinder to cut the metal pieces. A pair of tin snips and electric cutting shears got the job done. It was refreshing not having a nose and mouth full of metal dust particles for a change. I'm pretty certain I won't be able to have an MRI done for at least a couple months after I'm done with all the fabrication! With all the metal dust impregnated in my skin, I probably won't even get through airport security

I enjoyed fabricating these pieces more so than the hotside parts mainly because I didn't need to use the grinder to cut the metal pieces. A pair of tin snips and electric cutting shears got the job done. It was refreshing not having a nose and mouth full of metal dust particles for a change. I'm pretty certain I won't be able to have an MRI done for at least a couple months after I'm done with all the fabrication! With all the metal dust impregnated in my skin, I probably won't even get through airport security

bentley429isBAC

10 Year Member

Thanks bentley

Welded a few more pieces in around the turbo discharge. Gives it more of a finished look as opposed to just a square hole.

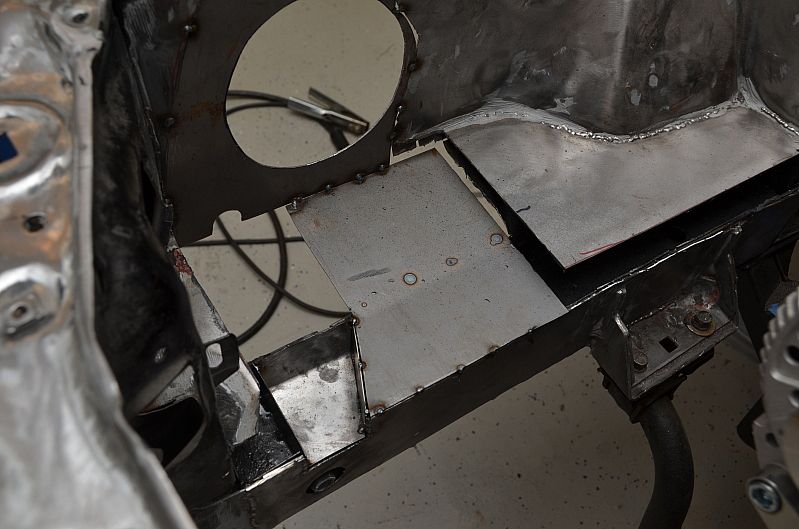

Also fabricated the lower radiator mount. This will get drilled and tapped for 2 mounting holes. I'll bolt the bottom radiator mounting flange to it. Rubber isolators will be used to dampen vibrations. I'll weld this to the frame once the engine is out.

Next up is fixing up the discharge tube hole...

Welded a few more pieces in around the turbo discharge. Gives it more of a finished look as opposed to just a square hole.

Also fabricated the lower radiator mount. This will get drilled and tapped for 2 mounting holes. I'll bolt the bottom radiator mounting flange to it. Rubber isolators will be used to dampen vibrations. I'll weld this to the frame once the engine is out.

Next up is fixing up the discharge tube hole...

I knew I saw a missing lower radia

I knew I saw a missing lower radiator saddle. Your garage floor is far too clean to have actually done any of the work you have pictured,....I'm calling you out for buying prefabricated pieces and just posting pictures of them.Thanks bentley

Welded a few more pieces in around the turbo discharge. Gives it more of a finished look as opposed to just a square hole.

Also fabricated the lower radiator mount. This will get drilled and tapped for 2 mounting holes. I'll bolt the bottom radiator mounting flange to it. Rubber isolators will be used to dampen vibrations. I'll weld this to the frame once the engine is out.

Next up is fixing up the discharge tube hole...

Similar threads

- Replies

- 32

- Views

- 41K

Progress Thread

'67 Mustang 351C > C4 trans > Clueless 21 year old

- Replies

- 5

- Views

- 3K

- Replies

- 3

- Views

- 10K

- Replies

- 1

- Views

- 7K

- Replies

- 2

- Views

- 3K