- Dec 19, 2010

- 5,719

- 4,238

- 224

If we had to guess, how far out is this little trip of Dave's?

Great question.

If we had to guess, how far out is this little trip of Dave's?

I came up with a Home Depot solution.

I welded a shelf standard in the middle ...

I am actually shocked about this. I know we differ on opinion about somethings but after all your hard work you put this in there? You can't tell me that every time you open the hood you won't be thinking about this... could I bring a shelf support arm and slide it in there? you have to have something better than this laying around the garage Mike. You are way more creative than that. With all that hard work to make it what it is don't short change us now.

And lastly,...since we're shooting for a paint date,...it's realistic to shoot for a completion date after that. The car is 80% It runs, (but it's got issues) the interior needs work, and there is a buttload of time in reassembly final details.

Do you think I can finish by August 28th?

Then I can rename the thread....."Three years to the day, The Gila Monster Build".

Is it too late to go carbon fiber on the hood.And you'd be justified in that. I guess that the solution was more of a "lets see if this will work" variety rather than "what can I do to fix this"....And showing this thing in it's "raw state" isn't typically what I do.

I've said it before, every picture I take, I actually attempt to make sure that you don't see too much of the disaster garage, or even my shadow in the pic....In this pic set my shadow, too much of the garage, and an unfinished thought got shown.

( I must've been tired)

I need to make sure that before I do something completely irreversible that the surface on top can be worked, that I am not causing some stinkin side effect (i.e. causing too much crown), and that the fix can be made to look acceptable when it's done.

Think of it this way....... What you are seeing is a bone. I haven't put the skin on it yet.

Is it too late to go carbon fiber on the hood.

And lastly,...since we're shooting for a paint date,...it's realistic to shoot for a completion date after that. The car is 80% It runs, (but it's got issues) the interior needs work, and there is a buttload of time in reassembly final details.

Do you think I can finish by August 28th?

Then I can rename the thread....."Three years to the day, The Gila Monster Build".

Is it too late to go carbon fiber on the hood.

You know, I saw an overstock sale just the other day on carbon fiber fairmont hoods...

We'll see....Its one thing to have a goal, and another to set a hard fast date that will get you rushing through things and making mistakes. While that would be cool if you hit the date, with you new work schedule I would be surprised if full completion is realistic. I dont know how your summer is going so far, but mine is flying already.

Mike, I know it is WAY past time in your build for this, but have you seen this Offy piece on EBay or anything like it?

http://m.ebay.com/itm/NOS-Offy-Offe...carb-intake-manifold-/152051983297?nav=SEARCH

If it is what I think, on attached log style intake/heads, the old top gets cut or milled off, and the new multi carb top gets welded on. And some porting is a little easier in between. At least that is how these worked on the Corvair. Without cutting off the intake log flat with the face of the manifold, making something from scratch that lines up with the port, and hoping you pick good spots for the new intake bolts, this is a better deal. Anyone actually used one?

Three little throttle bodies and a mega squirt system on Rainbow Dash (the light blue Fairmont in the planning stage for my girl) might be in my range of skills.

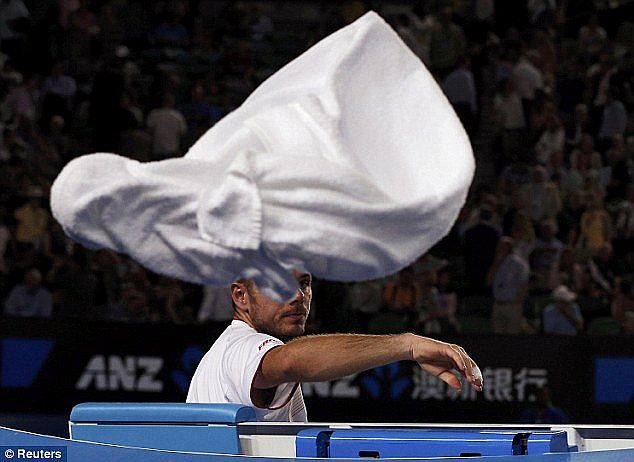

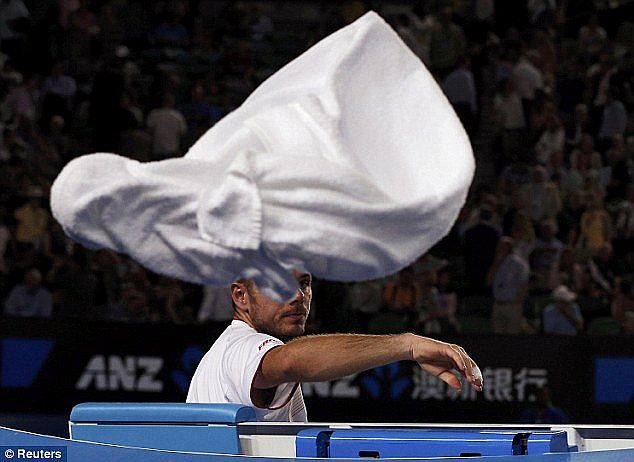

THIS is what happens when you screw with your work schedule and try taking Wednesday off Mike.

Get the symbolism?

That's me. throwing in the towel. The hood is proving to be one more thing that is the proverbial "more than I can chew" item.

This bastard. This thing looked like this at 10 AM. The center rib stripped, and ready for me to start trying to straighten the rib, and the surrounding sheet metal.

The only difference is,..This is the hood at 6PM.

After I've worsened the overall surface condition as opposed to making it better, and,......this is the second time it's been stripped. There was an attempt to cover this mess in filler. It is just so freakin bad, I cannot.

The skin is all kind of warped and stretched. I attempted to do a heat shrink, despite the fact that every other time I've tried this I make it worse. Today was no different. Even though I have a oxy/acetylene torch w/ a small tip, the process that you can watch on You tube that makes the metal shrink tight, only manages to create a huge dimple in the hood. When I beat the imple back to flat, the shrink goes away, and now I've got an even worse mess to contend with.

The center of the hood is F'd. Maybe a bodyman could fix it,...maybe he'd tell me to throw the bit ch away and get a different hood. (That body man doesn't even know how close I was to doing that today)

I don't have a shrinking hammer/dolly and I'm not eve sure that that will matter. The problem is compounded by the center rib. When you try to either lower, or raise the adjacent sheet metal.....guess what happens to that rib?

Damn straight......It raises/lowers right along with the other metal.

Again,....If Fairmont was still current enough for me to find yet another hood locally, I'd attempt to start on G hood V,.......(Fck,....there's been so many, I don't even know what version to call this one..)

Let's just say V 5.0.

The last hood was damaged. It was so damn dirty, I couldnt even see the low spots in the rib. Couple that to that warpage that comes as a by product from welding the G-nostrils on there, and the whole thing goes to hell in a handbasket.

Too bad they don't have snow in the winter time down here,.....I'd pull a Iowa Nick (@95BlueStallion ), and stack this failure in the garage, and use it as a big assed sled next winter.

S'cuse me while I go around the corner and,.....

.'

NO, says the finger......

NO, says the finger......So then,...You're looking for me for a hood, and all you come up with is a T-shirt?While browsing for a new hood for you, I came across this. You should probably get one, Mike. I dont see it staying in production for too terribly much longer.

http://rover.ebay.com/rover/1/711-5...0001&campid=5335821607&icep_item=252417923728

And for all your paint chip eating needs.

http://rover.ebay.com/rover/1/711-5...0001&campid=5335821607&icep_item=272249491626