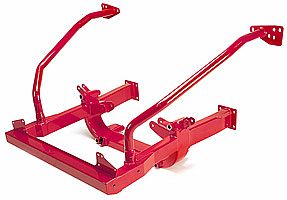

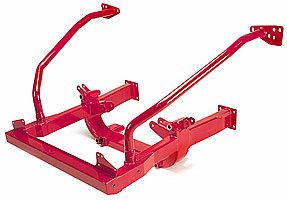

I left out "resto" for a reason. At this point there is little but the roof and front frame rails left original on the car. Anyways, I ordered my new rear suspension, everything but the coilovers that is, today. I got the competition engineering magnum 4 link kit, qa1 chrome moly rod ends xmr and *** 10-12 which means that they have a 3/4 inch shaft and 5/8 hole with a radial static load rating of over 40000 pounds. I also got the competition engineering panhard bar and anti roll bar. I sold the 289 and the versailles rear last weekend and came up with enough money to buy the rear suspension components and another 9 inch housing. I don't really have any questions, I'm just pumped about getting my new parts and hopefully ending up with a rolling chassis by the end of summer (I have to get a heidts super ride first). Thought I would share my joy with you all. I will get up some pictures when I get all the parts and when they are installed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

65 mod project build (ordered parts)

- Thread starter 351w_swap

- Start date

-

Sponsors (?)

Where did you order the Competition engineering parts from? I don't know if there is an Orielly Autoparts around you put you can save money on the frieght and shipping if you go threw them.

It is a great feeling knowing that you have parts coming and work that needs to be done. You car sound pretty intense and a very complete build, I cant wait to see some pics.

It is a great feeling knowing that you have parts coming and work that needs to be done. You car sound pretty intense and a very complete build, I cant wait to see some pics.

The problem with the local parts stores is not that they do not carry the parts, it is their prices which dont even compare to mail order. I ordered from autofabracecars.com. I have seen them all over the internet and decided to give them a try. They were very friendly over the phone and the best pricing on all of it. The shipping only ended up being $40 by the time it was done and the total was $818.00 which was awesome considering that even jegs or summit were going to charge me closer to 1000 for the same parts. The stores around me would have charged me double what I payed and none of them offer price matching. It sounded like they had all but the panhard bar in stock and it is going to be shipped out tomorrow.

Now I just have to find a place that I can get a DOM 2 inch diameter U bend so that I can mount up the front 4 link brackets. After everything is put in the car and I determine the ride height I am going to figure out what size coilovers I need and order those. After I get the rear suspension built I can start on the sheet metal which will be a ton of fun. I dont have a ton of experience but I do have some tools and it will be great to install the sheetmetal and have the mustang looking like a car again.

Now I just have to find a place that I can get a DOM 2 inch diameter U bend so that I can mount up the front 4 link brackets. After everything is put in the car and I determine the ride height I am going to figure out what size coilovers I need and order those. After I get the rear suspension built I can start on the sheet metal which will be a ton of fun. I dont have a ton of experience but I do have some tools and it will be great to install the sheetmetal and have the mustang looking like a car again.

Im going to pick up a heidts super ride coilover MII front end. I want to put some 13 inch cobra disks on the front. It will have a power rack and pinion steering setup with the tubular arms. I havent found a setup I like better than the heidts and plenty of people have them and I have not heard any bad about them so I figure that is the way to go.

I am planning on going with the Heidts MII crossmember as well. I agree with you on not hearing anything bad about the Heidts kit. It seems to be the best and comes with good instructions. The only bad thing I have heard about the kit is that the coilovers (QA1 I think) are rather harsh riding. Have you heard anything like that?

I haven't heard anything about the coilovers but I am building a car the feels like it is riding on rails so a little harsh riding is ok. The back coilovers will be qa1 as well so it really isnt a big deal that they ride a little rough. If I really dont like it, I can just change the springs, they are relatively cheap and should interchange relatively easily (easily compared to the rest of the build).

Here is before

And here is now but the firewall and engine bay sheetmetal were removed last night. I also got a new rear end housing last night. It is an early 80's truck housing and I got it for $50 (best deal i have got from that junk yard, he seems to think his parts are made of gold).

I will be using my 351w for a while after I paint it with a t56 but I want to build a twin turbo 408 stroker eventually.

And here is now but the firewall and engine bay sheetmetal were removed last night. I also got a new rear end housing last night. It is an early 80's truck housing and I got it for $50 (best deal i have got from that junk yard, he seems to think his parts are made of gold).

I will be using my 351w for a while after I paint it with a t56 but I want to build a twin turbo 408 stroker eventually.

Attachments

I wish i could, I don't have access to a camera for a week, it left on spring break. I will get a pic up when it gets back. Honestly, it is really scary to have the firewall removed because there is so little left now and a lot of work is ahead of me. When I removed the shock towers I found some real nice holes under it and I am contemplating the straight part of the rails off and replacing it with some 2*3 tube because I have plenty left over. It just never ends.

mdjay

Premium Sponsor

Im going to pick up a heidts super ride coilover MII front end. I want to put some 13 inch cobra disks on the front. It will have a power rack and pinion steering setup with the tubular arms. I havent found a setup I like better than the heidts and plenty of people have them and I have not heard any bad about them so I figure that is the way to go.

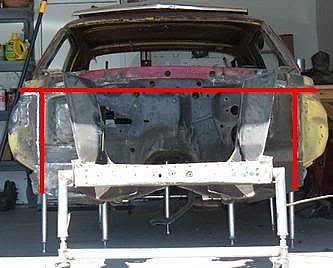

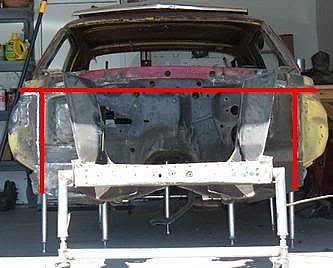

It's a good idea to run a brace from the firewall to the front sub. Kinda like the Chevy front clips. Ex.

Attachments

It's a good idea to run a brace from the firewall to the front sub. Kinda like the Chevy front clips. Ex.

I know it is a good idea to run a brace to the firewall but im not sure its necessary with the way that I ran my "subframe connectors".

BlackGMC

Your idea about cutting things off sounds pretty good. Just make a ton of measurements before. Are you planning on running some tubing behind the new firewall?

I do make sure to take plenty of measurements of everything to make sure I can build the correct mounting points into the sheet metal. What do you mean by putting tubing behind the firewall? What type of a design are you thinking of? I thought about running a tube brace between the door posts but I am not sure yet. I havent really decided what I am going to do for a dash yet either. I may keep the same one, or do something custom from fiberglass, or put in a sn95 dash, I haven't decided yet. I was thinking I might not but in a brace if I leave the old steel one in the car but if I do either of the other two options, I will brace it.

Attachments

the reason I mentioned the bracing behind the firewall was for a mounting location for a G-Brace (A bar that goes from the firewall to the front frame), see pic below. I was planning on running a G-Brace cause I will be going to a MII suspension like you plan on running. With the elimnation of the shock tower the front frame might move up and down depending on the load. This is what I was thinking running 1 1/2 square tubbing behind the firewall, that way I have solid mounts for the new pedals, AC, Bracing, etc. Since your all ready torn everything out you could easily tie into your subframe and You could also do away with the front torque boxes. Just an idea.

Attachments

mdjay

Premium Sponsor

the reason I mentioned the bracing behind the firewall was for a mounting location for a G-Brace (A bar that goes from the firewall to the front frame), see pic below. I was planning on running a G-Brace cause I will be going to a MII suspension like you plan on running. With the elimnation of the shock tower the front frame might move up and down depending on the load. This is what I was thinking running 1 1/2 square tubbing behind the firewall, that way I have solid mounts for the new pedals, AC, Bracing, etc. Since your all ready torn everything out you could easily tie into your subframe and You could also do away with the front torque boxes. Just an idea.

This logic brings full circle with the direction I was suggesting.

There is the possibility of flex between the front frame and body as noted. Yours would be lessened by the frame you're building, but the body can still flex. The chassis looks pretty good. Just tie the body to it.

I for one found out there's a limit to what kind of horsepower you can put through the unibody frame. Even if you tie it every which way but loose. So you're definately heading in the right direction

Thanks, you just cleared up another question. I was thinking about using those "g-bars" although I was unaware that that is what they were called, but I did not know how it would help to tie into the firewall if there is no brace to hold it in place. I didnt think about running a bar accross the car and tying it into the rest of the frame/body. Good idea. Maybe I will pick up some DOM and the braces into the sheet metal.

Should I center the pinion on the rear end or should I make the axle tubes the same length? I think I want a 3.50 trac loc or a spool, I havent decided which yet. The truck housing that I bought has a taper near the end. I met a guy at the junkyard with a jig that can do it but he said that he cuts a section out of the tubes in the center and butt welds it back together to retain the taper and old housing ends. I dont want to do that. I want to put in new housing ends that will accept the explorer rear disks. If I get new torino style housing ends will they fit in the tubes without the taper which are 3.25 inch OD?

mdjay

Premium Sponsor

Thanks, you just cleared up another question. I was thinking about using those "g-bars" although I was unaware that that is what they were called, but I did not know how it would help to tie into the firewall if there is no brace to hold it in place. I didnt think about running a bar accross the car and tying it into the rest of the frame/body. Good idea. Maybe I will pick up some DOM and the braces into the sheet metal.

It still helps without the inside bracing. Most are not in the position to completely frame up the car. Since you're gutted, go for it. Same with the roll bar for the rear.

Well, I got my rod ends from QA1 today, they look pretty awesome, unfortunately I can't do anything with them until I get the rest. I saw that the ends were in and got kind of excited so I went and bought a 20 ft length of 1 3/4, 11ga wall thickness, DOM tubing and a junk center section to make my own rear end narrowing jig. With any luck, the rest of my parts will be in tomorrow and then saturday I can work on collecting some explorer rear brakes which I came across at the junkyard today and installing the rear end. It is finally coming together!

Similar threads

- Replies

- 11

- Views

- 991

- Replies

- 35

- Views

- 4K

- Replies

- 12

- Views

- 2K

- Replies

- 14

- Views

- 2K