What really messes things up is when folks add a bumpsteer kit to 96+ spindles thinking that is the solution for correcting the problem. This has nothing to do with the OP's setup and more of a generalization as to what i've seen on the forums and Bookface.

Bear with me for a minute and try to visualize this.

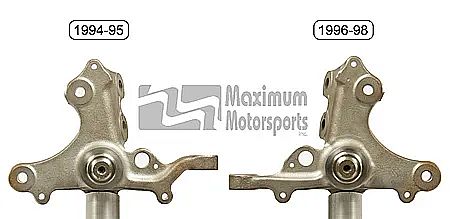

96+ cars lowered the steering rack. On the K-member, and the mount points on the spindles roughly 1" lower than 79-95 k-member/spindles. Let's ignore the Max Motorsports K-member which uses the 96+ lowered steering rack mounts (why they recommend 96+ spindles with their setup). Most guys are going to have a fox style K-member which uses the 1" higher mounting point for the rack.

So higher mounting point for the rack, and lower mounting point on the spindles. You may or may not get bumpsteer depending on how low the car is and other factors (offset rack bushings to drop the rack would help a ton here).

But assuming an impectect setup, the solution would be to raise the mounting points on the spindles or drop the rack. But, often times i see guys add a bumpsteer kit which includes spacers to push the tie rod ends further down, making the problem worse. This is the opposite of what you want to do as you want the tie rod ends higher. I browse over a ton of FB posts where folks say they run 96+ spindles on a stock K-member and added a bumpsteer kit to "fix the problem". 99.9% of people never even measure it because the entire process it a total PITA (i've done it...it sucks).

I'm not saying you can't make it work, but you just need to pick the right parts. If i were doing a stock K-member with 96+ spindles, i would get some offset steering rack bushings and install the rack in the lowest position possible, and then stick with stock tie rod ends to keep the mount point on the spindles as high as possible. You may not even ever notice any bumpsteer at all.