Little update for you hungry little Mustang tech addicts out there.

Spent half the day yesterday running around town looking for random stuff I needed to progress on the build, but I spent the other half of the day spinning wrenches. In short, this is what I did:

Stabbed the cam back in.

Degreed it. (Comp called for a 112* ICL, my measurements showed a 111*, so that's good.)

Checked cam end play. (Right at .005", so that's good.)

Slapped a head on and checked piston to valve clearance. Roughly .115" clearance on the intake and .185" on the exhaust, which is plenty. So what they say is true, Twisted Wedge heads will clear 1986 flat top pistons! Woo hoo!

Here are some pics of the PtV checking. I can't believe how EASY it is! If you do this right, it is absolutely cake. After doing this once, I don't know why everybody doesn't check PtV when putting new heads and/or a new cam in. I'll try to describe it step-by-step for ya here.

1. Install and degree your cam (this is actually the hardest part).

2. Coat the top of the piston and cylinder walls with oil. Also coat the combustion chamber on the head, the valve faces, and the quench area of the head (deck around the combustion chamber) with oil. This step is key in not messing up your clay.

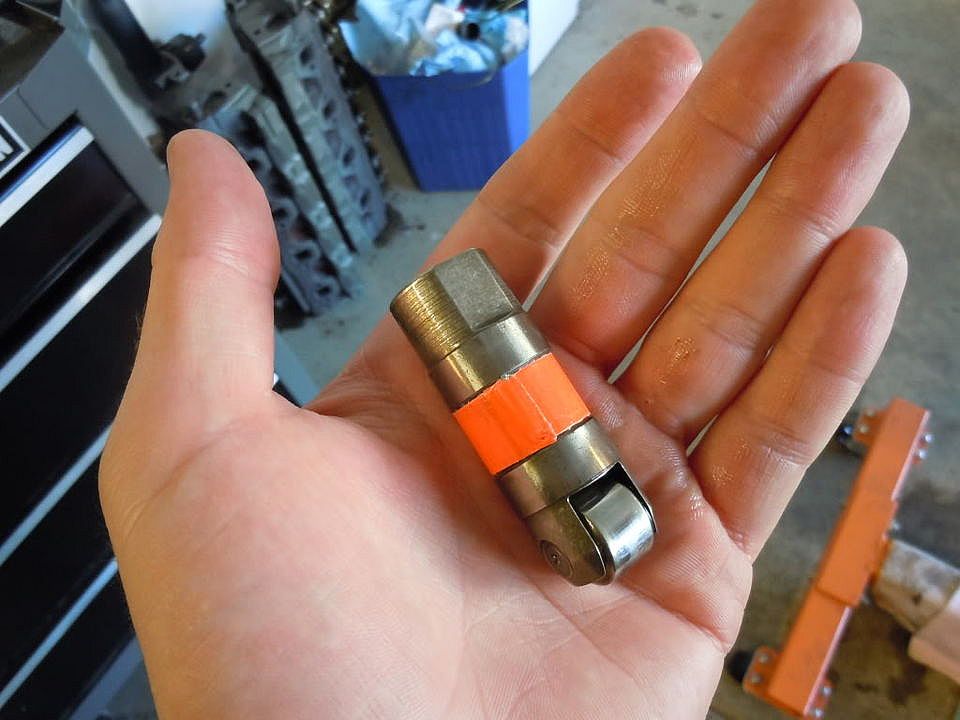

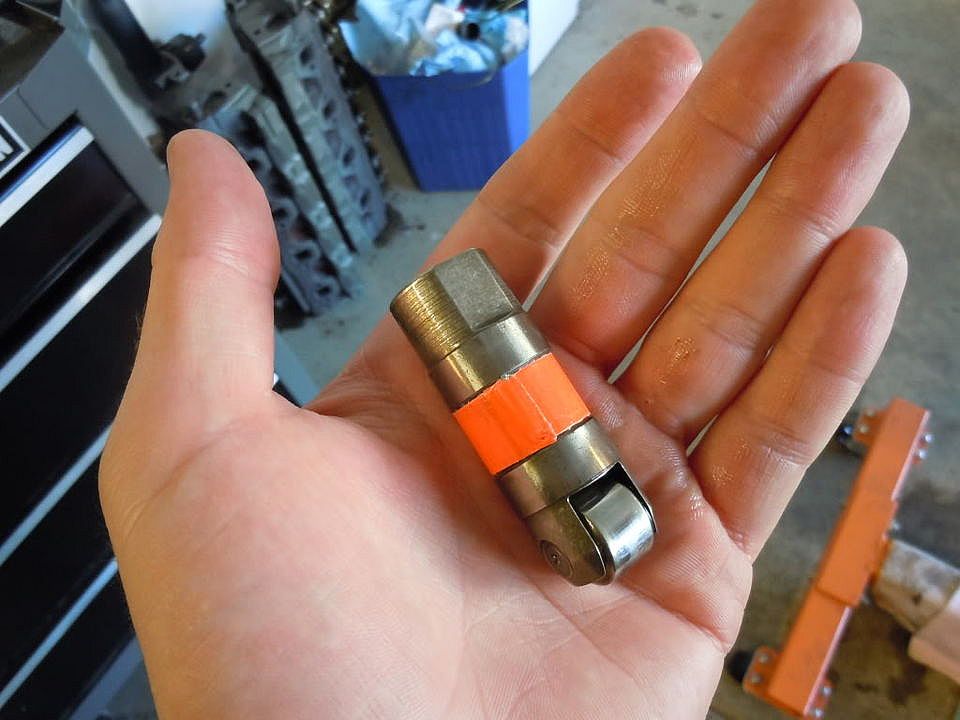

3. Install solid lifters, or hydraulic lifters converted to solid (Super easy with stock lifters. Take them apart, flip the plunger, and reassemble without the spring.) I used two of my old stock lifters for this, and marked them with orange duck tape.

4. Lay down a lump of clay, about 1/4" thick, on the piston where the valves will be nearest to. Rotate the engine so the piston is about half way up the cylinder on its compression stroke. See pic.

5. Use an old head gasket (in other words, one that has been compressed to the proper thickness, NOT a new gasket), and put it on the block along with the head alignment dowels. Put the head on the block and install and hand tighten 4 head bolts/studs around the cylinder being checked. You do not need to torque the bolts to spec, just hand tighten.

6. Install the pushrods and rocker arms (with a little oil on the contact points). Adjust the rocker arms to "0" preload, or, in other words, until there is no more movement in the pushrod, but DON'T over tighten, this will begin to compress the spring and lift the valve, and your measurement will be off.

7. Turn the engine over (in the operating direction) 2 full revolutions, until you are once again on the compression stroke. If, at any time, the engine wants to stop turning, STOP! Your valve has probably contacted the piston, and you're hosed. Your PtV is "0".

8. Pull the head and the valvetrain off.

9. Rotate the engine until the piston is at TDC.

10. Slice the clay where the valve marks are the deepest with a razor. Measure the thinnest part of the clay with a dial caliper (I left the clay on the piston for this, you may choose to take it off the piston.) If you have enough clay thickness (valve clearance) you're done! If not, I feel bad for you. You have to either cut valve grooves in your piston or get a milder cam. OR, in some cases, you can advance or retard your cam to gain clearance on one valve, but you'll reduce clearance on the other.

Ta Daaaa!

Spent half the day yesterday running around town looking for random stuff I needed to progress on the build, but I spent the other half of the day spinning wrenches. In short, this is what I did:

Stabbed the cam back in.

Degreed it. (Comp called for a 112* ICL, my measurements showed a 111*, so that's good.)

Checked cam end play. (Right at .005", so that's good.)

Slapped a head on and checked piston to valve clearance. Roughly .115" clearance on the intake and .185" on the exhaust, which is plenty. So what they say is true, Twisted Wedge heads will clear 1986 flat top pistons! Woo hoo!

Here are some pics of the PtV checking. I can't believe how EASY it is! If you do this right, it is absolutely cake. After doing this once, I don't know why everybody doesn't check PtV when putting new heads and/or a new cam in. I'll try to describe it step-by-step for ya here.

1. Install and degree your cam (this is actually the hardest part).

2. Coat the top of the piston and cylinder walls with oil. Also coat the combustion chamber on the head, the valve faces, and the quench area of the head (deck around the combustion chamber) with oil. This step is key in not messing up your clay.

3. Install solid lifters, or hydraulic lifters converted to solid (Super easy with stock lifters. Take them apart, flip the plunger, and reassemble without the spring.) I used two of my old stock lifters for this, and marked them with orange duck tape.

4. Lay down a lump of clay, about 1/4" thick, on the piston where the valves will be nearest to. Rotate the engine so the piston is about half way up the cylinder on its compression stroke. See pic.

5. Use an old head gasket (in other words, one that has been compressed to the proper thickness, NOT a new gasket), and put it on the block along with the head alignment dowels. Put the head on the block and install and hand tighten 4 head bolts/studs around the cylinder being checked. You do not need to torque the bolts to spec, just hand tighten.

6. Install the pushrods and rocker arms (with a little oil on the contact points). Adjust the rocker arms to "0" preload, or, in other words, until there is no more movement in the pushrod, but DON'T over tighten, this will begin to compress the spring and lift the valve, and your measurement will be off.

7. Turn the engine over (in the operating direction) 2 full revolutions, until you are once again on the compression stroke. If, at any time, the engine wants to stop turning, STOP! Your valve has probably contacted the piston, and you're hosed. Your PtV is "0".

8. Pull the head and the valvetrain off.

9. Rotate the engine until the piston is at TDC.

10. Slice the clay where the valve marks are the deepest with a razor. Measure the thinnest part of the clay with a dial caliper (I left the clay on the piston for this, you may choose to take it off the piston.) If you have enough clay thickness (valve clearance) you're done! If not, I feel bad for you. You have to either cut valve grooves in your piston or get a milder cam. OR, in some cases, you can advance or retard your cam to gain clearance on one valve, but you'll reduce clearance on the other.

Ta Daaaa!