Well, I haven't been posting here too much lately. I've been really busy. But, I feel this needs to be shown to the rest of you.

Backstory:

The stock 302 in my hatchback went to crap, due to the water pump.

So, I bought a 347 from CHP. I have been doing the swap myself.

Upgrading as much as I can this time around. Nothing is stock except the block itself unfortunately.

Ive been taking pictures during the process, and planned to make a nice video of the rebuild.

Anyways,

I ordered a Canton oil pan, 7 Quart, Road race/Street/Strip version. Looking like this.

Slosh baffle, Magnetic plugs, 2 extra quart capacity. Sounds GREAT. Hopefully this will be the first foxbody ive owned that doesn't leak oil!!

I also ordered their windage tray. The matching model that mounts to the main caps.

Their matching pickup for the oil pan

And the Mounting kit for the windage tray.

When I recieved all the parts, at first glance everything looked awesome.

I was excited, Im always excited when big boxes of parts show up.

It looked like a big improvement over the stock parts....

OK! The day has come.

Time to mount the windage tray to the main caps.

I remove the crappy no name bolts from caps 2 and 4, and replace them with the ARP stud kit for the windage tray.

So far, so good.

I go to test fit the windage tray on the ARP Main studs.

The problems begin!

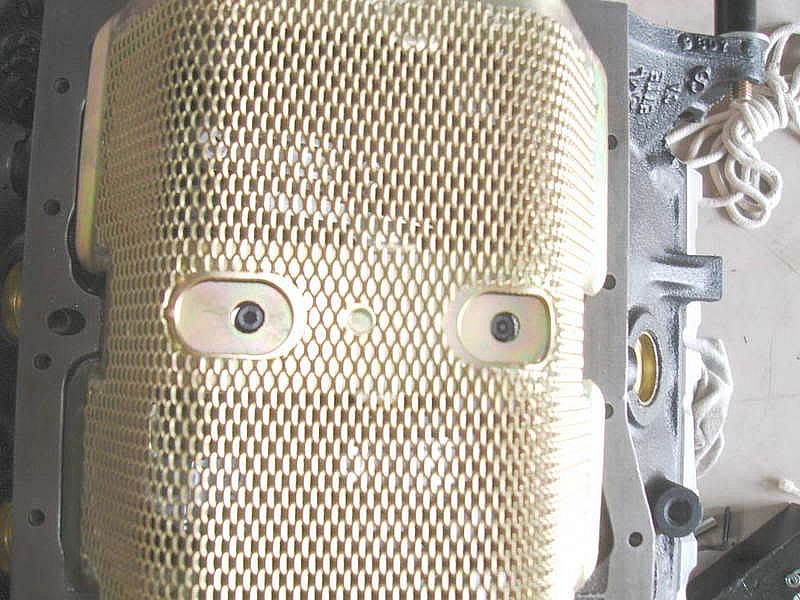

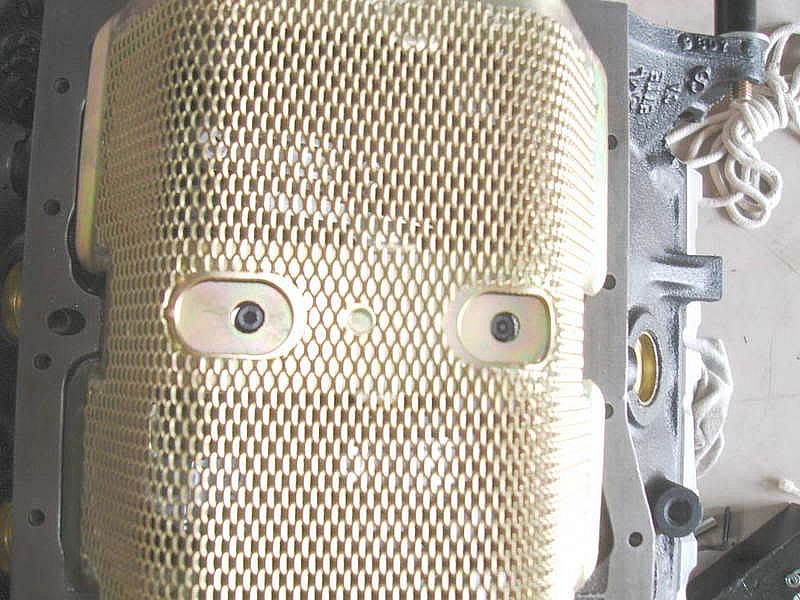

I guess Canton Blindly drills their holes in their windage tray, or their template is garbage.

As you can see in the picture, the holes are too far apart to fit on the studs. Not even close enough for a hammer to get it down.

Not that big of deal so far. So, I widen the holes in the correct areas. I went back and forth about 10 times to test fit, so I didn't widen the holes too much.

Now, the windage tray slides down nice and easy. Its a perfect fit, and doesn't have any extra play in it.

Then I notice that the tray doesn't sit completely flat. It will wobble diagonally slightly. The studs were all the same height, It was the support bar that was welded in sloppy and not measured.

But, I found if it flexes under the bolt pressure and flattens out. OH wonderful. So I continue.

Next, I turn the crank over to see how much clearance I have.

*CLANK* First rod bolt to come up smacks the windage tray screen.

Canton's instructions say nothing about clearance issues on a stroker, and come with nothing to properly space the tray up farther.

So, after a trip to the hardware store. I buy 20 washers, just in case I need that many. So, eventually i find that 12 washers are needed between the studs and tray to properly clearance the rod bolts.

I go back to turning the crank over. To celebrate my victory.

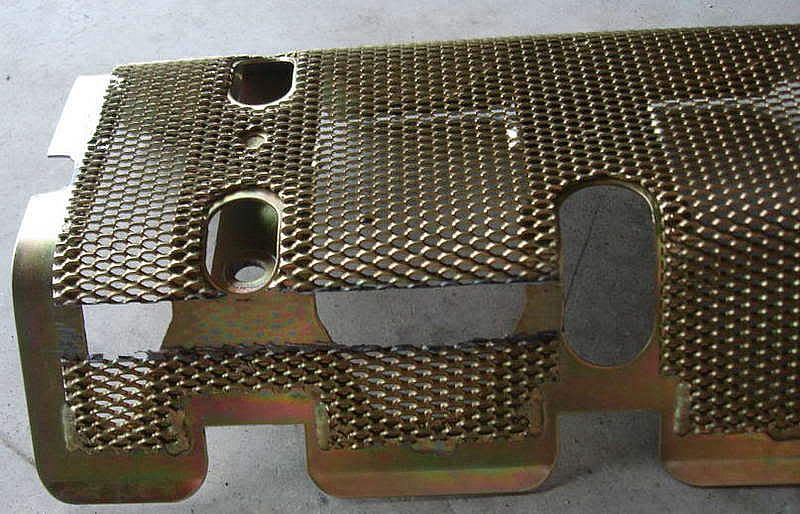

It turns out cantons design puts a flat piece of metal over the 1st rod bolt, instead of a screen portion like the other areas.

The screen is naturally welded on TOP of this metal support structure. So, it hangs much lower in this ONE spot.

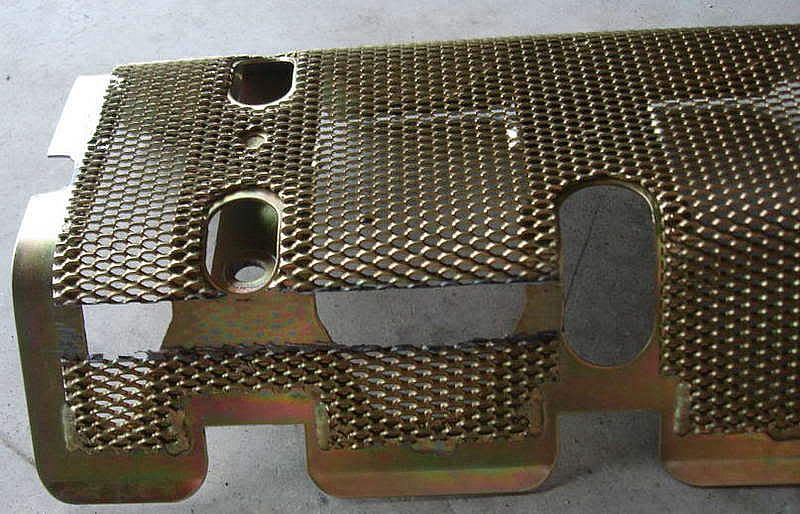

Instead of using MORE washers to clear this ONE rod bolt. I decided to cut the troublesome piece of metal out.

Why cut you ask? Because, What would be the point of HAVING the windage tray if its not even NEAR the crank and shimmed up SO high for ONE rod bolt.

So, the answer to this is clear.

I mark, I cut. Heres the results of that problem.

OK!

The windage tray is mounted. It now clears all the rod bolts. Everything is good. Thank god. .........

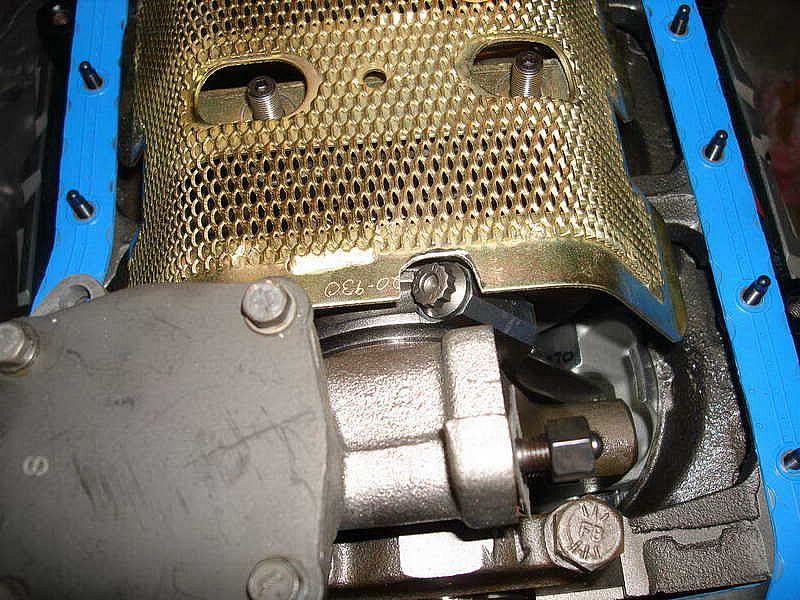

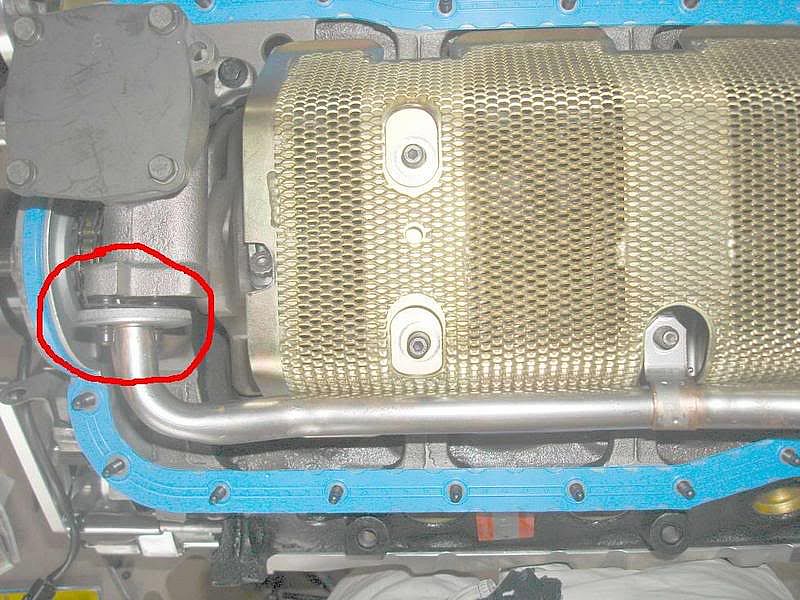

I go to test fit the oil pickup onto the oil pump.

The windage tray sticks WAY too far out for the pickup to even come close to bolting to the oil pump without severe bending and possibly breaking the pickup tube.

Heres a picture of the closest I could get the pickup to the pump without bending the tube.

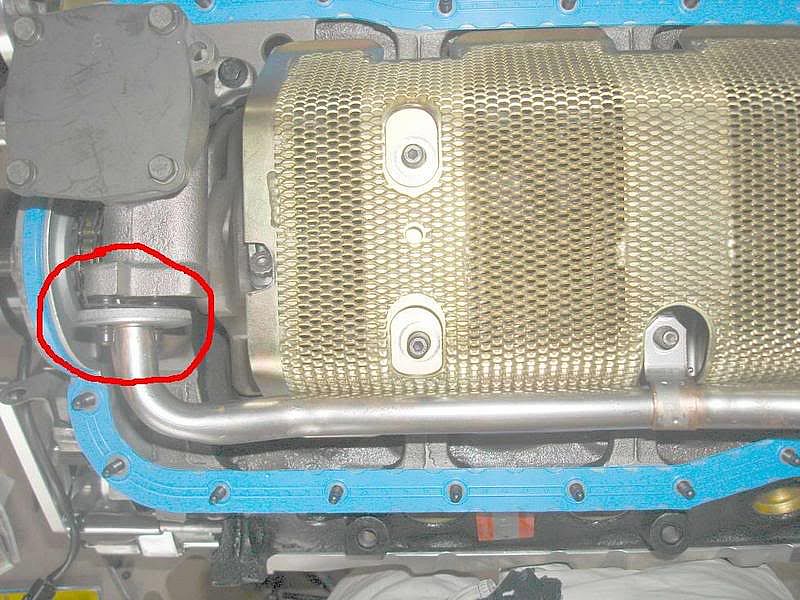

So, naturally. Whats the only way to gain clearance here without bending the tube, and taking the risk of weakening or cracking it? MORE CUTTING!

So, I break out the marker again. I mark where the tube is rubbing against the windage tray. Time to get that air compressor moving again.

Heres a picture of my marks before the cutting.

After some careful work with some air tools, trying not to cut anything but the screen itself.

Heres the result. Pretty damn good job.

ALRIGHT

PROBLEM SOLVED, EVERYTHING SHOULD WORK.....FINALLY.....

Close! BUT, Still not enough clearance to bolt the pickup and pump together. You could try and bend the flange on it. But, it will leave a gap, and suck air instead of oil.

Im not having that!

So, back to the air tools.

I took some metal out of the area that was rubbing still. Which you can see is now silver. Eventually, it was close enough that the gasket would seal correctly.

OK, FINALLY! Everything is in! I can put the oil pan on and be done with this nightmare ........... ...

Well, I went to test fit the pan. It wouldn't clear the ARP oil pan studs.

Half the bolt holes were centered, and half were catching threads of the studs. But, not in one direction. Every hole that was catching, was catching on a completely different side.

Some holes were too far left, some too far right, Some too close to the pan.. etc etc. You wouldn't be able to hammer this down over the ARP studs without damaging them, or the pan.

By this time i was sick of taking pictures and said f%!# it, So no pictures of the oil pan issues.

So, after lots of marking with a pencil, and lots of careful tweaking of the holes, being careful not to overdue anything and give any chance to provoke an oil leak.

Finally, it smoothly fit down onto the bottom of the block.

BUT THE PAN WOULD ROCK SLIGHTLY, it did not sit completely flat.. Thats always a good sign things are going to seal correctly

But, its flimsier than the stock oil pan. It flexed and seated down flat when I tightened everything.

I figured, I must be doing something wrong. Maybe the studs are bent somewhere? So, I went and found my stock oil pan. It slipped over the ARP studs just fine, and sat flat. So my block was fine, and the studs were fine. It really was the damn pan.

Somewhere during this wonderful week of wasted time. I was looking at the oil pan, and noticed one of the baffle walls was welded in crooked. The sheet of metal was not flush with the kickout of the oil pan like it should have been, it stuck out probably 1/16th of an inch on one side. Nothing bad, and didn't effect anything really. It was just something I noticed. Great quality control.

So, I wasted probably a week dicking with only canton products.

I'll never buy from them again

-Derek

Backstory:

The stock 302 in my hatchback went to crap, due to the water pump.

So, I bought a 347 from CHP. I have been doing the swap myself.

Upgrading as much as I can this time around. Nothing is stock except the block itself unfortunately.

Ive been taking pictures during the process, and planned to make a nice video of the rebuild.

Anyways,

I ordered a Canton oil pan, 7 Quart, Road race/Street/Strip version. Looking like this.

Slosh baffle, Magnetic plugs, 2 extra quart capacity. Sounds GREAT. Hopefully this will be the first foxbody ive owned that doesn't leak oil!!

I also ordered their windage tray. The matching model that mounts to the main caps.

Their matching pickup for the oil pan

And the Mounting kit for the windage tray.

When I recieved all the parts, at first glance everything looked awesome.

I was excited, Im always excited when big boxes of parts show up.

It looked like a big improvement over the stock parts....

OK! The day has come.

Time to mount the windage tray to the main caps.

I remove the crappy no name bolts from caps 2 and 4, and replace them with the ARP stud kit for the windage tray.

So far, so good.

I go to test fit the windage tray on the ARP Main studs.

The problems begin!

I guess Canton Blindly drills their holes in their windage tray, or their template is garbage.

As you can see in the picture, the holes are too far apart to fit on the studs. Not even close enough for a hammer to get it down.

Not that big of deal so far. So, I widen the holes in the correct areas. I went back and forth about 10 times to test fit, so I didn't widen the holes too much.

Now, the windage tray slides down nice and easy. Its a perfect fit, and doesn't have any extra play in it.

Then I notice that the tray doesn't sit completely flat. It will wobble diagonally slightly. The studs were all the same height, It was the support bar that was welded in sloppy and not measured.

But, I found if it flexes under the bolt pressure and flattens out. OH wonderful. So I continue.

Next, I turn the crank over to see how much clearance I have.

*CLANK* First rod bolt to come up smacks the windage tray screen.

Canton's instructions say nothing about clearance issues on a stroker, and come with nothing to properly space the tray up farther.

So, after a trip to the hardware store. I buy 20 washers, just in case I need that many. So, eventually i find that 12 washers are needed between the studs and tray to properly clearance the rod bolts.

I go back to turning the crank over. To celebrate my victory.

It turns out cantons design puts a flat piece of metal over the 1st rod bolt, instead of a screen portion like the other areas.

The screen is naturally welded on TOP of this metal support structure. So, it hangs much lower in this ONE spot.

Instead of using MORE washers to clear this ONE rod bolt. I decided to cut the troublesome piece of metal out.

Why cut you ask? Because, What would be the point of HAVING the windage tray if its not even NEAR the crank and shimmed up SO high for ONE rod bolt.

So, the answer to this is clear.

I mark, I cut. Heres the results of that problem.

OK!

The windage tray is mounted. It now clears all the rod bolts. Everything is good. Thank god. .........

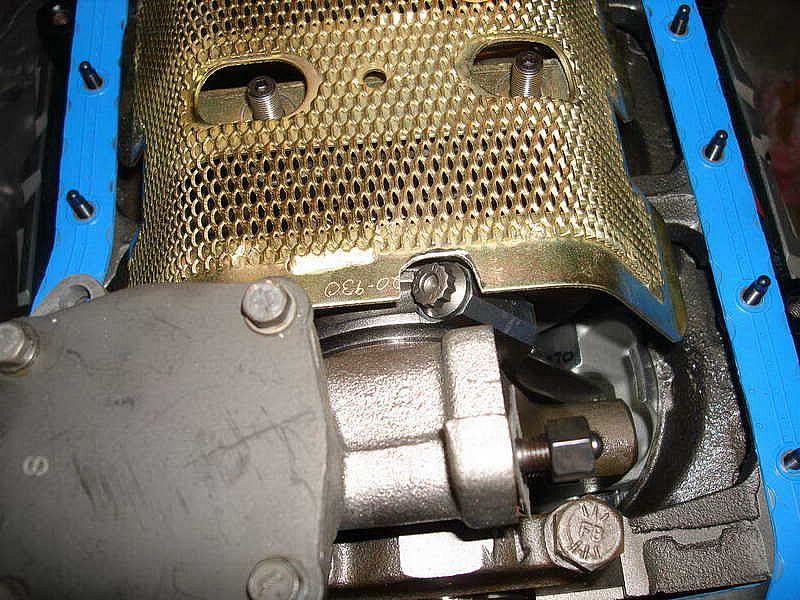

I go to test fit the oil pickup onto the oil pump.

The windage tray sticks WAY too far out for the pickup to even come close to bolting to the oil pump without severe bending and possibly breaking the pickup tube.

Heres a picture of the closest I could get the pickup to the pump without bending the tube.

So, naturally. Whats the only way to gain clearance here without bending the tube, and taking the risk of weakening or cracking it? MORE CUTTING!

So, I break out the marker again. I mark where the tube is rubbing against the windage tray. Time to get that air compressor moving again.

Heres a picture of my marks before the cutting.

After some careful work with some air tools, trying not to cut anything but the screen itself.

Heres the result. Pretty damn good job.

ALRIGHT

PROBLEM SOLVED, EVERYTHING SHOULD WORK.....FINALLY.....

Close! BUT, Still not enough clearance to bolt the pickup and pump together. You could try and bend the flange on it. But, it will leave a gap, and suck air instead of oil.

Im not having that!

So, back to the air tools.

I took some metal out of the area that was rubbing still. Which you can see is now silver. Eventually, it was close enough that the gasket would seal correctly.

OK, FINALLY! Everything is in! I can put the oil pan on and be done with this nightmare ........... ...

Well, I went to test fit the pan. It wouldn't clear the ARP oil pan studs.

Half the bolt holes were centered, and half were catching threads of the studs. But, not in one direction. Every hole that was catching, was catching on a completely different side.

Some holes were too far left, some too far right, Some too close to the pan.. etc etc. You wouldn't be able to hammer this down over the ARP studs without damaging them, or the pan.

By this time i was sick of taking pictures and said f%!# it, So no pictures of the oil pan issues.

So, after lots of marking with a pencil, and lots of careful tweaking of the holes, being careful not to overdue anything and give any chance to provoke an oil leak.

Finally, it smoothly fit down onto the bottom of the block.

BUT THE PAN WOULD ROCK SLIGHTLY, it did not sit completely flat.. Thats always a good sign things are going to seal correctly

But, its flimsier than the stock oil pan. It flexed and seated down flat when I tightened everything.

I figured, I must be doing something wrong. Maybe the studs are bent somewhere? So, I went and found my stock oil pan. It slipped over the ARP studs just fine, and sat flat. So my block was fine, and the studs were fine. It really was the damn pan.

Somewhere during this wonderful week of wasted time. I was looking at the oil pan, and noticed one of the baffle walls was welded in crooked. The sheet of metal was not flush with the kickout of the oil pan like it should have been, it stuck out probably 1/16th of an inch on one side. Nothing bad, and didn't effect anything really. It was just something I noticed. Great quality control.

So, I wasted probably a week dicking with only canton products.

I'll never buy from them again

-Derek