I need to confirm that I am clocking the distributor correctly in this new motor. First, I briefly guesstimated what it looked like in the old car (wiring harness pointing to passenger side). Next I brought cylinder one, driver side front most, up to top dead center by sticking a 1/4" drive extension down the spark plug hole and rotating the motor in the rotation of operation (righty tighty) until the extension came all the way up and stopped. then I verified this is on top dead center of the compression stroke (start of ignition stroke) by looking at the valves...both are closed.

then I put the stock broken cap on because it has an idicator for #1 cylinder. the cap only goes on the distributor one way. so I know i want the rotor to end up pointing at the #1 tower on the cap once it is in and sitting flush to the block.

I ended up having to rotate the distributor rotor about 1 post counter clockwise because as the distributor mates to the cam gear it seems to turn 1 post clockwise. it ended up sitting right under the #1 post on the cap when I had it torqued down and flush to the block. this is the correct procedure?

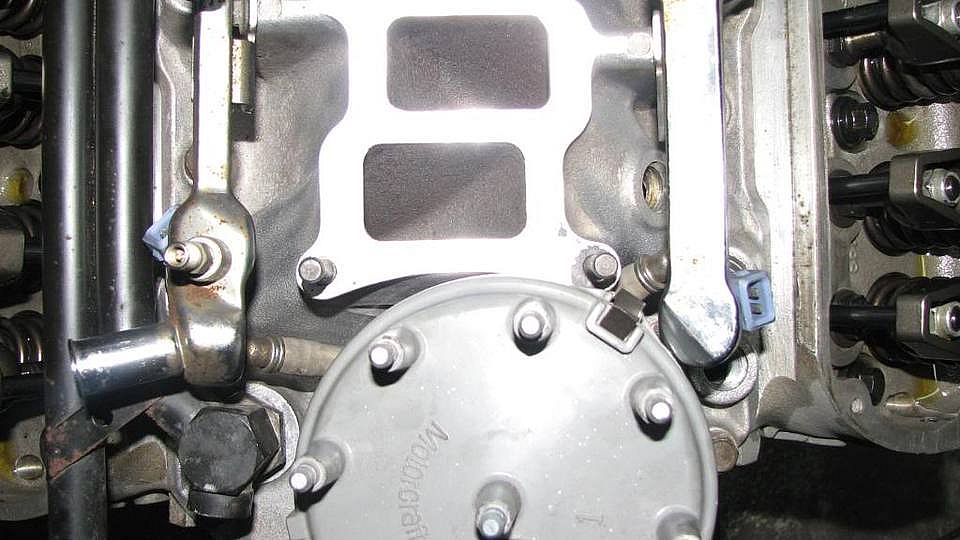

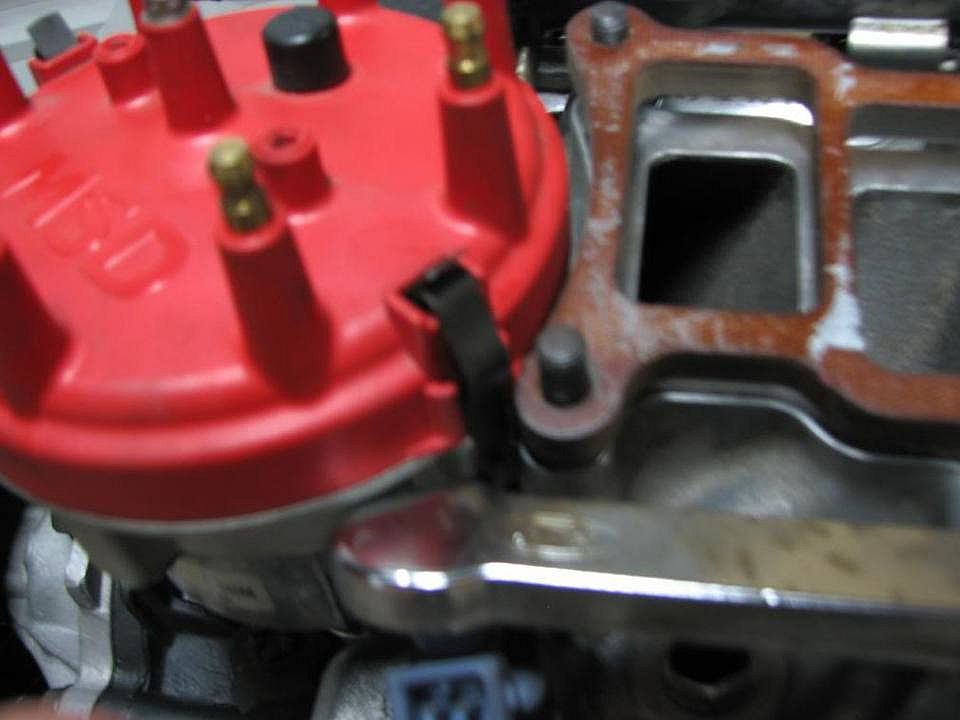

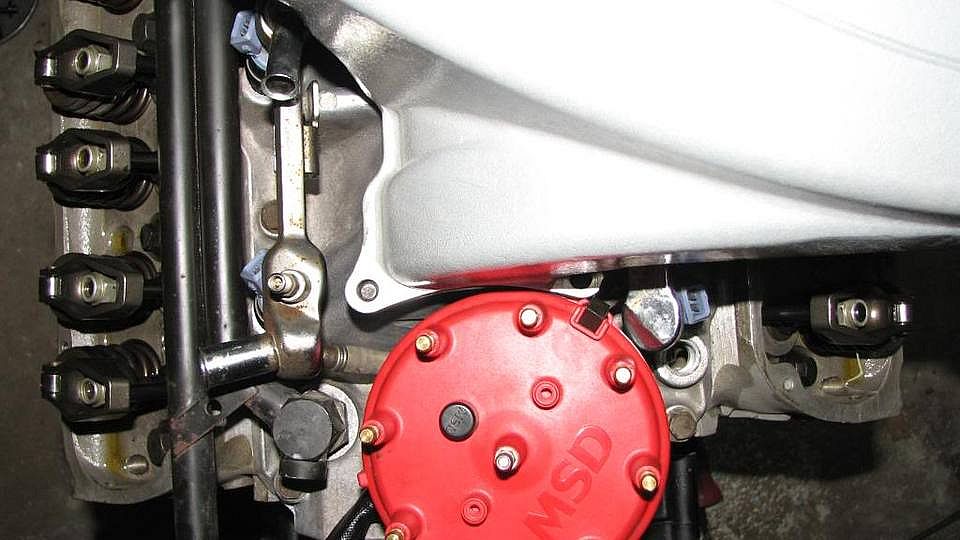

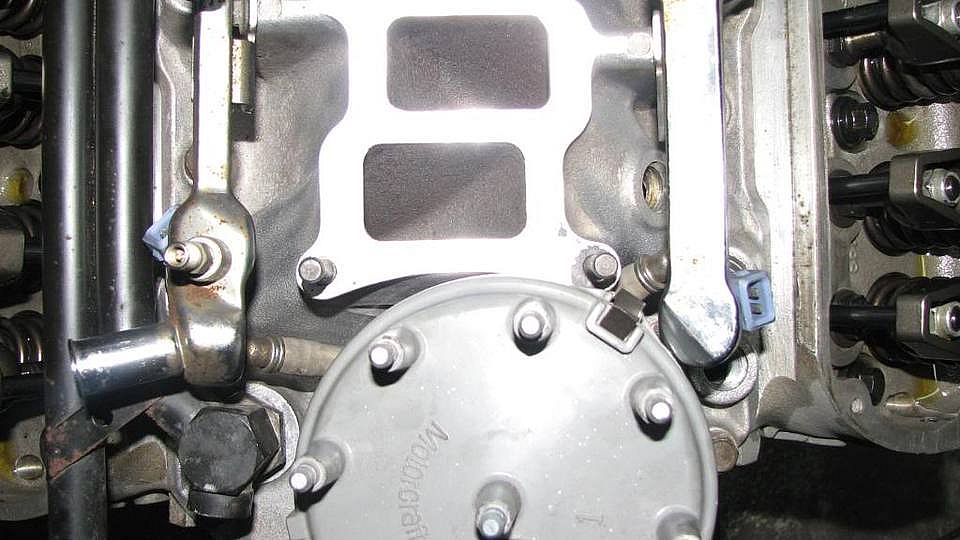

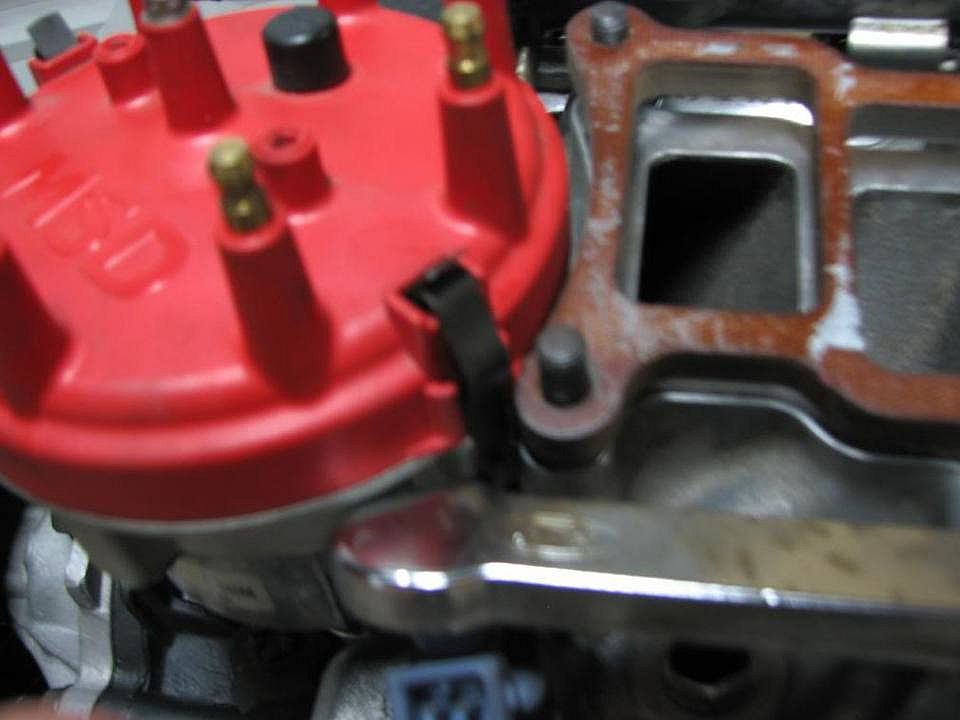

now we has more issues...this lower is so big that I'm afraid about the clearance with the distributor and cap.

so I put on the cap we are going to use and the phenolic spacer

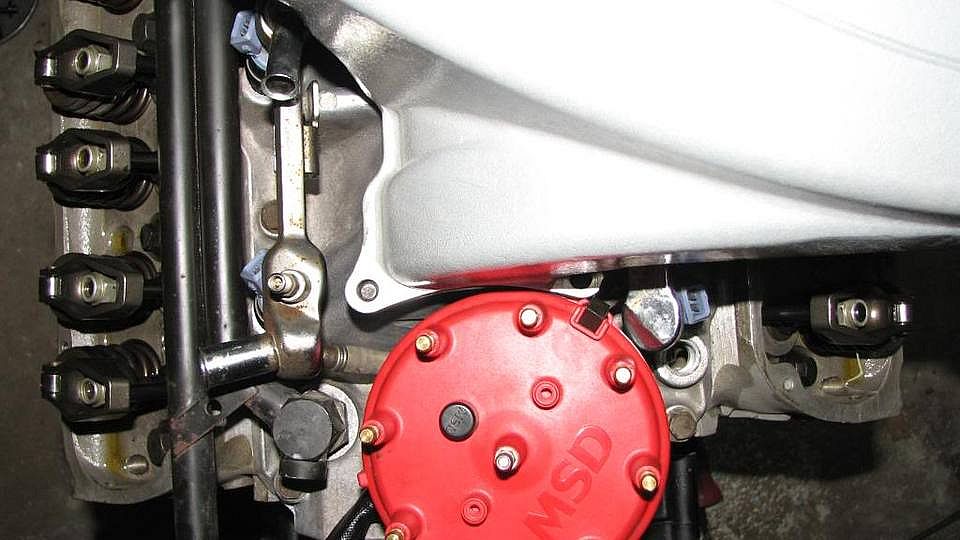

and then the upper intake

should I clearance the phenolic spacer or the distributor, or leave it. I don't like how it's sitting because I have to basically force it in. If I install the phenolic spacer and upper, then the distributor, the disty is next to impossible to get in. it is pushing the phenolic spacer slightly off center.

then I put the stock broken cap on because it has an idicator for #1 cylinder. the cap only goes on the distributor one way. so I know i want the rotor to end up pointing at the #1 tower on the cap once it is in and sitting flush to the block.

I ended up having to rotate the distributor rotor about 1 post counter clockwise because as the distributor mates to the cam gear it seems to turn 1 post clockwise. it ended up sitting right under the #1 post on the cap when I had it torqued down and flush to the block. this is the correct procedure?

now we has more issues...this lower is so big that I'm afraid about the clearance with the distributor and cap.

so I put on the cap we are going to use and the phenolic spacer

and then the upper intake

should I clearance the phenolic spacer or the distributor, or leave it. I don't like how it's sitting because I have to basically force it in. If I install the phenolic spacer and upper, then the distributor, the disty is next to impossible to get in. it is pushing the phenolic spacer slightly off center.

Attachments

-

adammotor070.jpg78.9 KB · Views: 65

adammotor070.jpg78.9 KB · Views: 65 -

adammotor068.jpg77.7 KB · Views: 92

adammotor068.jpg77.7 KB · Views: 92 -

adammotor069.jpg73.8 KB · Views: 77

adammotor069.jpg73.8 KB · Views: 77 -

adammotor067.jpg70 KB · Views: 67

adammotor067.jpg70 KB · Views: 67 -

adammotor074.jpg76.9 KB · Views: 72

adammotor074.jpg76.9 KB · Views: 72 -

adammotor075.jpg59.3 KB · Views: 77

adammotor075.jpg59.3 KB · Views: 77 -

adammotor076.jpg35.7 KB · Views: 75

adammotor076.jpg35.7 KB · Views: 75 -

adammotor077.jpg54.1 KB · Views: 67

adammotor077.jpg54.1 KB · Views: 67 -

adammotor078.jpg49.6 KB · Views: 71

adammotor078.jpg49.6 KB · Views: 71 -

adammotor079.jpg45.9 KB · Views: 79

adammotor079.jpg45.9 KB · Views: 79 -

adammotor080.jpg44.5 KB · Views: 76

adammotor080.jpg44.5 KB · Views: 76 -

adammotor072.jpg64.9 KB · Views: 65

adammotor072.jpg64.9 KB · Views: 65 -

adammotor073.jpg84.8 KB · Views: 57

adammotor073.jpg84.8 KB · Views: 57