Engine Bad engine shaking at idle

- By sav22rem22

- Fox 5.0 Mustang Tech

- 26 Replies

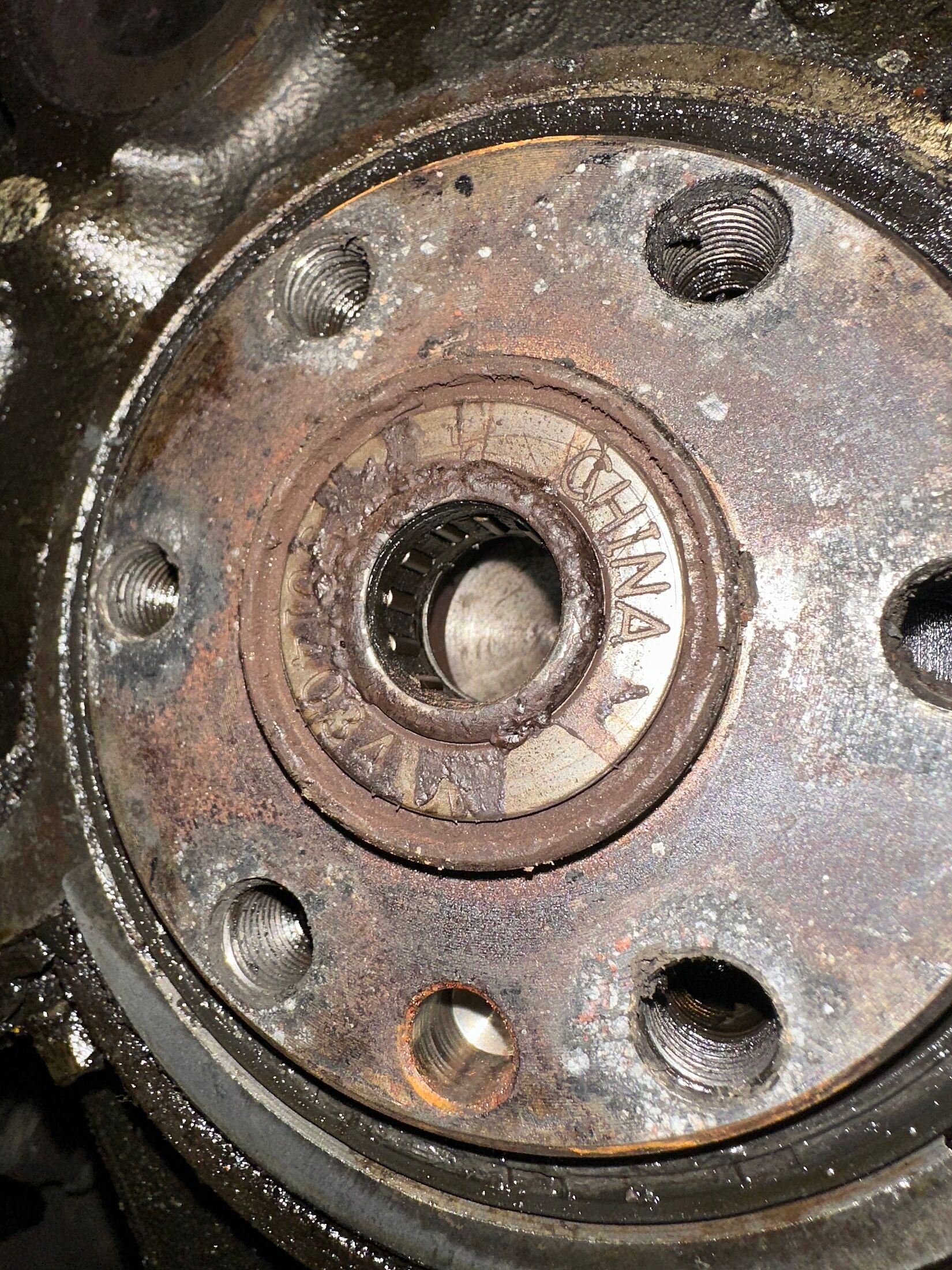

Also, has anyone ever seen a pivot stud like this? I’ve got a new one and while the top part looks identical I’m not sure what the cylindrical piece below it is. It also seems a little too wobbly which I was under the impression that the pivot stud shouldn’t move at all.

It's possible that they made 2 to install 2 separate capacitors with different ratings?

It's possible that they made 2 to install 2 separate capacitors with different ratings?  Otherwise I'm at a loss.

Otherwise I'm at a loss.