Diesel guys rock. I like to step bore, and like to put a block plate on a sleeved engine. Dry sleeves are okay, wet sleeves are much more risky.

I kind of remember what we discussed. Recap on the advice I gave back in 2014.

Down here in Hamilton Jet equiped Jet Sprint engines, pop top high compression pistons were illegal in most classes, so they decked the hell out of the factory iron six and eight cylinder blocks, and ran a copper head gasket with a reprofiled stock piston.

If thinwall, you could always sleeve an engine if it was rare. The normal rule was over bore 250 thou and use a 125 thou thick sleeve for 3.3 Vauxhall in line sixes, to get back to the stock 3.625" bore. It was a very common Hamilton Jet and oval track engine, and they got sleeved on occasion. You could over bore them to 3.700" or so, and

thats 87.5 thou thick between rebored cylinde sleeve to to the piston ring. Allways, somewhere, the sleeve was protecting a major crack or score. The over boring process on a thinwall 1978 engine is taking out metal in an area that is at best 130 thou thick, sometimes 90 thou. That 90 thou is certainly the case with 90% of all Cleveland 351's that have been sleeved. Hell, Ford Australia sleeved the 76 to 82 modle year blocks from the factory to recover the casting cost of an engine, and sold them to customers that way. Mainly due to core shift.

In those cases, the cylinder wall would have been daylighted and metal woould have clear air in certained places before the liner was popped in. That is okay as long as somewhere in the thrust face, there is 180 thou of metal supported. Normally, shell molded thinwall engines have egg shaped section, and they are thicker at the suporting bulkheads, and tapper down the 5-1/2 or so inches of cylinder to a minimum 130 or sometimes 90 thou with core shifting thickness. And core shifting can be 50 thou or more. The spun cast liner is very strong, stronger than a cast iron block, but any time you remove cast iron, you lesson the chance of the liner doing its job.

On the L28's and LD28 diesels, the factory sleeve kits were only 103 thou thick for a start, and the second or third rebuilds on the sleeved engine could end up 60 thou over, taking wall thickness down to 73 thou. You can go another 20 thou over from your current +20, about +40 thou is as much as I'd risk, but your block is hardfilled, so its not an issue really.

Liner shifting due to water ingress or overheating is so uncommon in an iron engine.

According to

How to Power Tune Rover V8 Engines for Road & Track

By Des Hammill, Veloce Publishing Ltd, 2005 ISBN 1903706173, 9781903706176 and 216 pages long

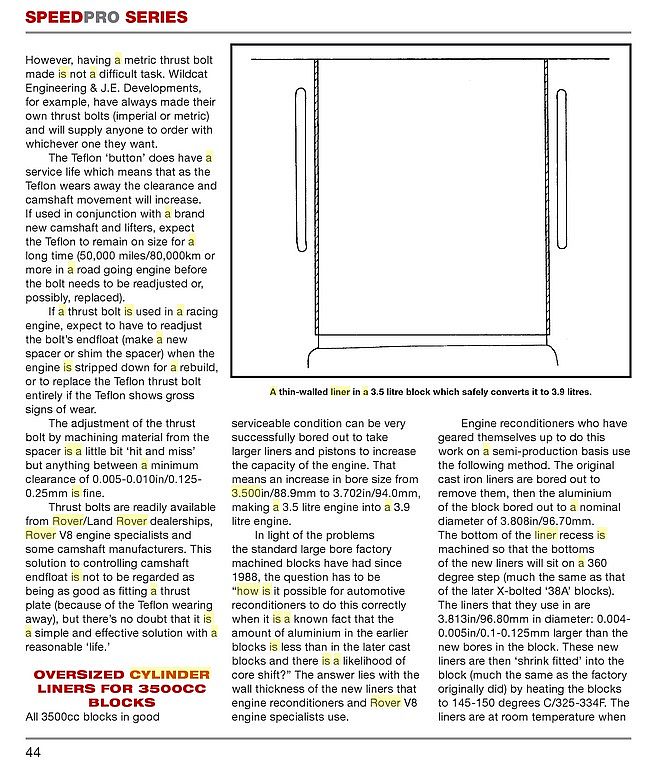

The reliable replacement thinwall liners are just 55 thou thick after machining to 3.702" in a bored out 3.5 Rover block.

Stock, the very unreliable liner is 91 thou thick wall for the 3.702" 3.9 liter Block.

page 44 to 45.

That is in an aluminum block, Mike, so if its cast iron, hardfilled and over bored, you can over bore to a 305 Chevy piston and still have about 55 thou of wall thinkness.

This is what I based my liner around, the prospect of saving any iron 200 or 250 Ford block using the common GM 4200 or Rover 3.5 style liners, and the common 3.625 or maybee 3.756 pistons, and having it survive three 30 thou over bores, +30, +60, +90. Its possiable!

Back in 1985 to 1994 when I had it, everyone suggested I used a Rover 3500 or Buick-Olds-Pontiac 215 in my old 58 PA Vauxhall, but that engine isn't something that mechanically locks its iron liner to the aluminum block. Either the B-O-P 215 cast in liner isn't inbeded, or the later Rover 3.5/3.9/4.2/4.6 shrink fit liner moves under overheating and heat gasket failure.

Collateral damage at normal rates is up to 3 to 4 Grand US to preheat, remove liners, quench and reheat and replace. Its the same with the alloy LS Chevies. Some just bore out the existing block with the liner still partly in.

That's why I'm a Cast Iron Charlie all the way. Alloy sux dead Cats and dead 215's and dead LS engines

Aren't you glad you used a junked 78 Maverick 250, you cheep a$$ed tight wad?

See the maladies of the 3.5 litRE "Wover Vee Eight"....

http://forum.britishv8.org/read.php?6,18390

I have little respect for English re-engineering. The Rover 3500 was better than the US 215, but it still had some blQQdt stupid engineering stuff ups.

You will never have a slipped liner, and the liners can be replaced much cheeper on an irin in line six than this 3.5 liter Rover with a moved liner

View: https://vimeo.com/14816047

heads are rich because they nickle and dime you to death for everything they do, even if they screw it up.

heads are rich because they nickle and dime you to death for everything they do, even if they screw it up.

........

........ ............

............