You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Build Thread 1978 Mercury Cyclone. The pig is in the pen.

- Status

- Not open for further replies.

-

Sponsors (?)

How about a push and pull spring setup with the pull stronger to return to closed, but it would reduce pedal effort, if it is too much.

I'm gonna post a pic first and let it speak for itself. ( Then I'll speak for the pic)

Can you say Wide,.......Open,.....Throttle?

This was done while my son sat in the car with his foot planted on the floor. I think I've finally figured out the necessary math to get the throttle actuated.

This was where I needed to adjust my thinking. I was trying to make the throttle easier to open by lengthening the actuator rod. What that did at the same time was increase the distance a cable had to pull on that lever to fully rotate the shaft to full open. You can see the original intersect point at the end of the lever. I moved it inboard, but at that point, the thing crashes into the throttle bodies, and is all over the linkage. Just like the three bears however, baby bear's spot is the sweet spot. The pedal is distinctly heavier, but not so bad as to give me a leg cramp or anything.

Now, the last hurdle is tackled. The engine can go fully together. But first I've got to pull the throttle cable back off, the brackets, levers and the "fix" for the gas pedal mount and tweak/paint them. The cable needs to be shortened up about 1/2", the interconnect cable that runs over the pulleys is gonna be increased in diameter to 3/32" ( But now I have an exact length template to work off of)

So then,. I've got a working system that I can now refine to make it as close to perfect as I can.

I give myself 2 thumbs up.

I can only give you one thumb up, but Im thinking about two of them. Great to see you figuring it out.

It's actually not bad as it is. I prefer a heavier pedal, I think it adds a little more feedback that way.How about a push and pull spring setup with the pull stronger to return to closed, but it would reduce pedal effort, if it is too much.

I think they're worse than they were actually. I can't run, I can't kneel, and they hurt if I stand on my feet too long.I'll give ya coupletoo!

BTW, hows the knees holding up?

It's just one big, easy going care-free existence to be in my skin.

Think maybe you didnt give yourself enough recovery time before you were back at the Monster? I'd check with the doc and physical therapist to see what you can do to improve. My grandma had double knee replacement and said she feels night and day better after. Everyone is different, but hopefully you can find a way to ease the suffering. Wait, they call that alcohol I think. I dont know, ask Dave

That-a-boy!

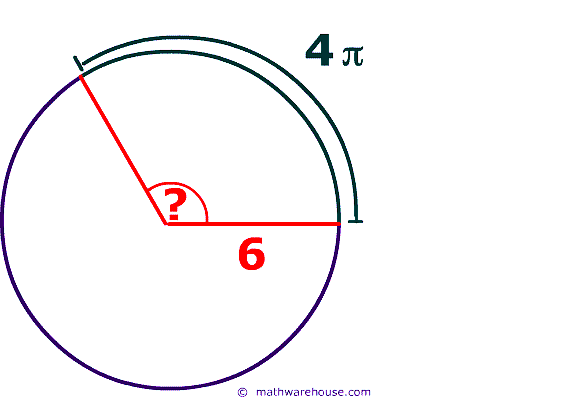

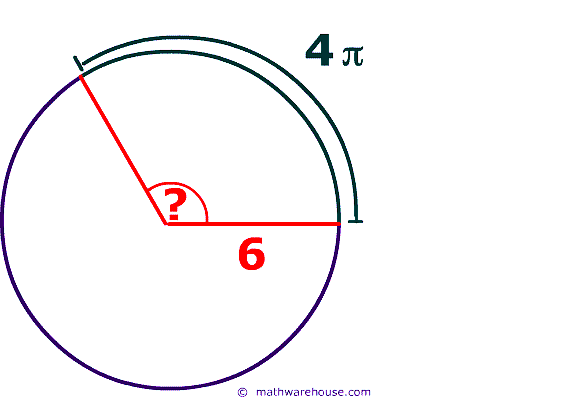

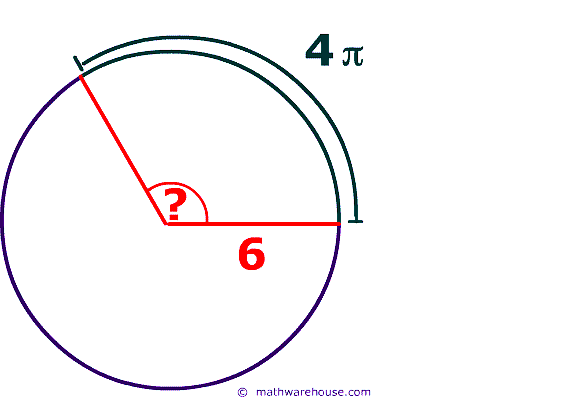

Nice work on the S=r.theta pull out calculations.

View: https://www.youtube.com/watch?v=Uxz9vy9QrR4

Throttle blade degrees swing is normally 79 to 81 degrees, the high side with curb idle removed. 80 degrees or summit like 0.7161875 radians.

BMW cut the throttle blade chamfer side down to a 6 degree chamfer, most other blades (Holley, Weber, Autolite, Motorcraft, Rochester, Carter) have a 12 degree angle to 'em.

The six ITB's have very little curb idle because the apperture leak on six throttles is a sh!+ load more than the 1 or 2 degrees of leak needed on, say, a 2-bbl Motorcraft, Autolite or Holley carbs primary system.

Its nice not to have to tell you the mathmatics of working out a 1-3/4" throotle cable pull out requirement from curb to wide open throttle, and working all that back through the degrees and then into radians. 1 radian is approx 57.295 deg

when convert 2 radians to degrees you multiply 2 by 180/pi. Now you obtain an answer at approx 114.590 degrees. Remember 2pi radians is equal to 360 degrees

If you got that all worked out physically, you don't need the crud above....

My neighbour (who was New Zealands first Rolux-En -Y gastric bypass...same thing my Mrs has had....) well, he departed this mortal coil due to Septasemia from the bone to bone contact in his knees. He was over 400 pounds by the time he was 18. Epic bear drinker, too. US Ford and Chevy guy, loved him less like a surrogate child, more like a daddy.

When he passed on last year, he was 365 pounds, the weight the high side of what he'd kept off for 40 years. So with your Dual Under pinnings, its unlikely to create other "other" problems.

To Your continued recovery, Mike. May your knees be tough as goats ones. Prey on this.....

Note Well:

As 340, 440 and Mopar 265 Hemi 6 pack owners know....is better like this.

Six pack ITB's all the way!

Nice work on the S=r.theta pull out calculations.

View: https://www.youtube.com/watch?v=Uxz9vy9QrR4

Throttle blade degrees swing is normally 79 to 81 degrees, the high side with curb idle removed. 80 degrees or summit like 0.7161875 radians.

BMW cut the throttle blade chamfer side down to a 6 degree chamfer, most other blades (Holley, Weber, Autolite, Motorcraft, Rochester, Carter) have a 12 degree angle to 'em.

The six ITB's have very little curb idle because the apperture leak on six throttles is a sh!+ load more than the 1 or 2 degrees of leak needed on, say, a 2-bbl Motorcraft, Autolite or Holley carbs primary system.

Its nice not to have to tell you the mathmatics of working out a 1-3/4" throotle cable pull out requirement from curb to wide open throttle, and working all that back through the degrees and then into radians. 1 radian is approx 57.295 deg

when convert 2 radians to degrees you multiply 2 by 180/pi. Now you obtain an answer at approx 114.590 degrees. Remember 2pi radians is equal to 360 degrees

If you got that all worked out physically, you don't need the crud above....

I think they're worse than they were actually. I can't run, I can't kneel, and they hurt if I stand on my feet too long.

It's just one big, easy going care-free existence to be in my skin.

My neighbour (who was New Zealands first Rolux-En -Y gastric bypass...same thing my Mrs has had....) well, he departed this mortal coil due to Septasemia from the bone to bone contact in his knees. He was over 400 pounds by the time he was 18. Epic bear drinker, too. US Ford and Chevy guy, loved him less like a surrogate child, more like a daddy.

When he passed on last year, he was 365 pounds, the weight the high side of what he'd kept off for 40 years. So with your Dual Under pinnings, its unlikely to create other "other" problems.

To Your continued recovery, Mike. May your knees be tough as goats ones. Prey on this.....

Note Well:

As 340, 440 and Mopar 265 Hemi 6 pack owners know....is better like this.

Six pack ITB's all the way!

Last edited:

That-a-boy!

Nice work on the S=r.theta pull out calculations.

View: https://www.youtube.com/watch?v=Uxz9vy9QrR4

Throttle blade degrees swing is normally 79 to 81 degrees, the high side with curb idle removed. 80 degrees or summit like 0.7161875 radians.

BMW cut the throttle blade chamfer side down to a 6 degree chamfer, most other blades (Holley, Weber, Autolite, Motorcraft, Rochester, Carter) have a 12 degree angle to 'em.

The six ITB's have very little curb idle because the apperture leak on six throttles is a sh!+ load more than the 1 or 2 degrees of leak needed on, say, a 2-bbl Motorcraft, Autolite or Holley carbs primary system.

Its nice not to have to tell you the mathmatics of working out a 1-3/4" throotle cable pull out requirement from curb to wide open throttle, and working all that back through the degrees and then into radians. 1 radian is approx 57.295 deg

when convert 2 radians to degrees you multiply 2 by 180/pi. Now you obtain an answer at approx 114.590 degrees. Remember 2pi radians is equal to 360 degrees

If you got that all worked out physically, you don't need the crud above....

My neighbour (who was New Zealands first Rolux-En -Y gastric bypass...same thing my Mrs has had....) well, he departed this mortal coil due to Septasemia from the bone to bone contact in his knees. He was over 400 pounds by the time he was 18. Epic bear drinker, too. US Ford and Chevy guy, loved him less like a surrogate child, more like a daddy.

When he passed on last year, he was 365 pounds, the weight the high side of what he'd kept off for 40 years. So with your Dual Under pinnings, its unlikely to create other "other" problems.

To Your continued recovery, Mike. May your knees be tough as goats ones. Prey on this.....

Note Well:

As 340, 440 and Mopar 265 Hemi 6 pack owners know....is better like this.

Six pack ITB's all the way!

See, that's why I actually liked my trig class. So many real world applications.

See, that's why I actually liked my trig class. So many real world applications.

Yeah, that one time that one guy built a one off engine with a one off ITB set up....

I decided to buy my very own drawing board, so I won't have so far to go when I have to go back to the drawing board.

The throttle linkage is unreliable. Although it'll open the ITB's now, it'll just pop off of the ball on every third attempt.

Something is binding/twisting/ over tolerance in this system.

I ordered a lokar unit yesterday. It'll require that I change both ends where the cable attaches. Compared to the factory cable assy. there'll be no internal return spring which is part of the causes of the binding that I currently am having.

So, that'll be a good thing.

The gas pedal end requires a tab with a hole drilled into it so I can pass a pin through a clevis to anchor that end..That pin is secured with a e-clip.Getting that tiny little "E-clip" on the end of the pin that far under the dash will be a serious PITA.....You'll probably be able to hear me btching 100 miles away.

That cable will be here Monday, so I'll have to focus on other stuff in lieu of that. Still to do is the external oil pump mounting, final torquing of the head studs, cleaning and installing, then lashing the rockers and pushrods. Filling the engine with oil, and priming the oiling system via a 90* attachment on a drill that I put on the bolt holding the pulley of the oil pump.

Once I get the oil system primed, I'll be able to put the radiator in, and fill the cooling system.

Dean, the T stat that I have in this engine is a 180 degree unit...wondering whether or not that needs to be upped, or left alone.

Bottom line should be by the late afternoon on Monday.......I should be looking at a possible restart.

Now that you added that last sentence to the post, it'll be next month before you try to start it. What were you thinking estimating a time line on a project???

Can you attach the cable to the pedal then install the pedal into the car? Maybe stick the cable through the firewall and attach it to the pedal then mount it to the floor?

Can you attach the cable to the pedal then install the pedal into the car? Maybe stick the cable through the firewall and attach it to the pedal then mount it to the floor?

Versus attaching the cable to the pedal under the hood, and then mounting the pedal...

LS Swap with DBW would eliminate the throttle linkage issues!

Otherwise, you'll figure out the cable mounting. I don't know how hard your seat is to remove, but when I do anything up under the dash, I find it's much easier to get my fat ass in there if I just pop the seat out!

I would think that unless you have cooling system capacity issues, the 180 t stat is fine. If the cooling system is inadequate it's inadequate whether the water starts moving at 160 or 180.

Otherwise, you'll figure out the cable mounting. I don't know how hard your seat is to remove, but when I do anything up under the dash, I find it's much easier to get my fat ass in there if I just pop the seat out!

I would think that unless you have cooling system capacity issues, the 180 t stat is fine. If the cooling system is inadequate it's inadequate whether the water starts moving at 160 or 180.

Oh yeah! I forgot he had cold engine blues! So I might try a 195 t stat. Or you might try CMA. I'll go back to figuring out self employed taxes. AGGH!

Who knew getting a 1099 would be such a pain. But after bouncing off the wall a couple of times I am good.

Who knew getting a 1099 would be such a pain. But after bouncing off the wall a couple of times I am good.

I did some revisions to your drawing board....something was off base timing by 20 degrees...

About four ting tings.

1. The thermostat only determins when the cooling system is allowed to start cooling the engine. You cannot influence the peak operation temparature by changing the themostat value up or down. The latter is a cooling capacity issue, and its checked by that old Julian Edgar method of un capped capacity testing. Thermostats only set a floor value , not a peak value on on engine temperature. IMHO, where:-

A. emissions,

B. component durablity under multiple cold starts,

C. cold catayst light off, and

D. warming the internal parts,

where those are most important, then a higher value is better in most cases.

If your drag racing, the first cold EFi run of the day is often the best, so you can lower the floor level, and gain a few tenths at the 1/8 or 1/4 mile.

2.Forged piston cars run cooler internally, on a 460, up to 100 degrees F cooler at various points in the rev range. The piston grain structure ensures a resistance to latent heating, and this becomes a major issue for cold start emissions on big bore engines, lesser as the bores get smaller. On your 3.7 ish bore, I'd still go for a hotter thermostat, but the quench heat under operation is decided by power, torque, the advance curve and the actual engine cooling, so its only during th first 5 minutes a hotter thermostat will influece anything.

3. Hardfilled blocks probably helps reduce peak heat by increasing the heat sink; evidence you supplied tends to suggest the water pump and cooling modifications have drastically lowered your expectedpeak temperature.

4. Your oil cooling rate is far greater, even with a big ass pump like that. Your crank windage reduction, and its solid lifters with huge oil drain back improvements will have added huge amount of additional oil cooling capacity to an engine that was gallaiered, sized and designed around a far lower flow rate of much hotter oil. Like 99 Bad Arse 1978 era Malise generation SAE Net horsepower.

Soooo...You can do Whatcha like.

Oh yeah. Adding Block rock is most likely going to act as a vibration dampener, so you won't hear knock and all the other stuff you do in a normal thin wall 250 Maverick engine. So its gonna be hard to burn the heck out of a forged piston, well oiled, hard blocked engine.

It needs a "TTBTB" sticker on the block.

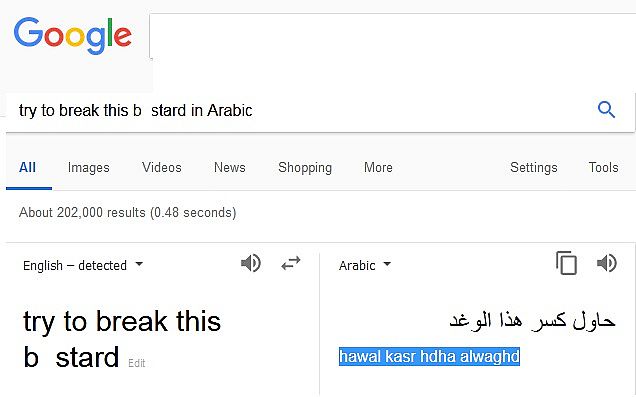

"prubirn tsu brekhn dem m@mzer" Yiddish

"tente quebrar esse b@st@rdo" Portuguese

"intenta romper este b@st@rdo" Spanish

"B@st@rdus conantur confringere" Latin

Oh, and lets not forget.....

hawal kasr hdha alwaghd in Arabic!

.......

Once I get the oil system primed, I'll be able to put the radiator in, and fill the cooling system.

Dean, the T stat that I have in this engine is a 180 degree unit...wondering whether or not that needs to be upped, or left alone.

Bottom line should be by the late afternoon on Monday.......I should be looking at a possible restart.

About four ting tings.

1. The thermostat only determins when the cooling system is allowed to start cooling the engine. You cannot influence the peak operation temparature by changing the themostat value up or down. The latter is a cooling capacity issue, and its checked by that old Julian Edgar method of un capped capacity testing. Thermostats only set a floor value , not a peak value on on engine temperature. IMHO, where:-

A. emissions,

B. component durablity under multiple cold starts,

C. cold catayst light off, and

D. warming the internal parts,

where those are most important, then a higher value is better in most cases.

If your drag racing, the first cold EFi run of the day is often the best, so you can lower the floor level, and gain a few tenths at the 1/8 or 1/4 mile.

2.Forged piston cars run cooler internally, on a 460, up to 100 degrees F cooler at various points in the rev range. The piston grain structure ensures a resistance to latent heating, and this becomes a major issue for cold start emissions on big bore engines, lesser as the bores get smaller. On your 3.7 ish bore, I'd still go for a hotter thermostat, but the quench heat under operation is decided by power, torque, the advance curve and the actual engine cooling, so its only during th first 5 minutes a hotter thermostat will influece anything.

3. Hardfilled blocks probably helps reduce peak heat by increasing the heat sink; evidence you supplied tends to suggest the water pump and cooling modifications have drastically lowered your expectedpeak temperature.

4. Your oil cooling rate is far greater, even with a big ass pump like that. Your crank windage reduction, and its solid lifters with huge oil drain back improvements will have added huge amount of additional oil cooling capacity to an engine that was gallaiered, sized and designed around a far lower flow rate of much hotter oil. Like 99 Bad Arse 1978 era Malise generation SAE Net horsepower.

Soooo...You can do Whatcha like.

Oh yeah. Adding Block rock is most likely going to act as a vibration dampener, so you won't hear knock and all the other stuff you do in a normal thin wall 250 Maverick engine. So its gonna be hard to burn the heck out of a forged piston, well oiled, hard blocked engine.

It needs a "TTBTB" sticker on the block.

"prubirn tsu brekhn dem m@mzer" Yiddish

"tente quebrar esse b@st@rdo" Portuguese

"intenta romper este b@st@rdo" Spanish

"B@st@rdus conantur confringere" Latin

Oh, and lets not forget.....

hawal kasr hdha alwaghd in Arabic!

Last edited:

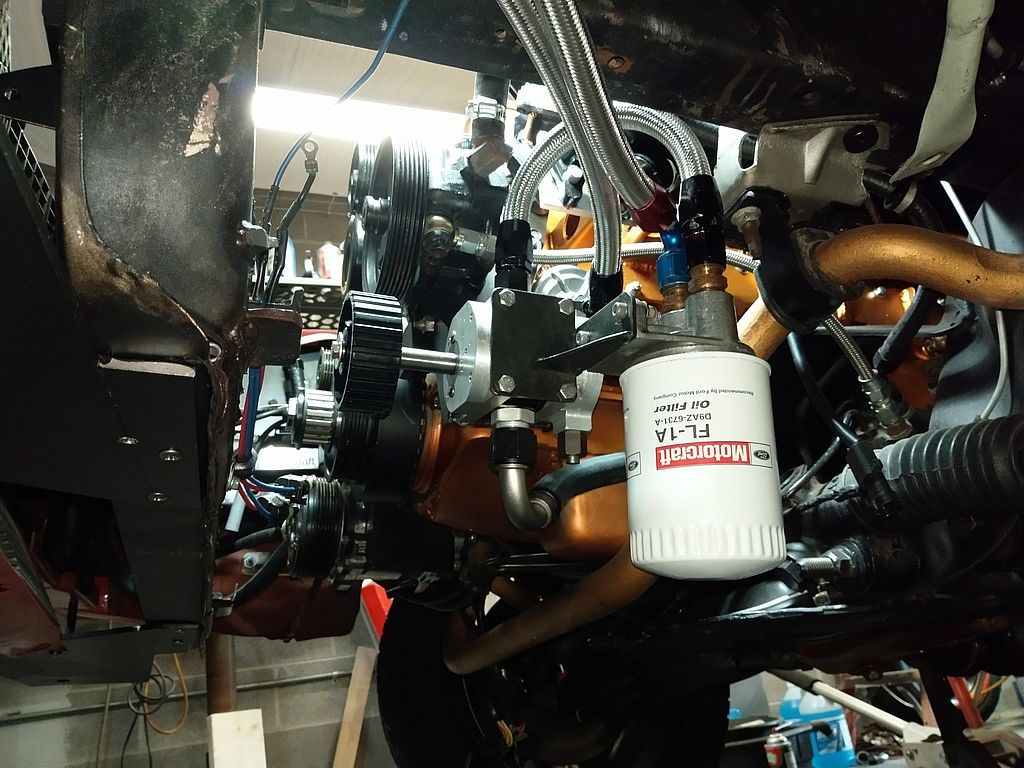

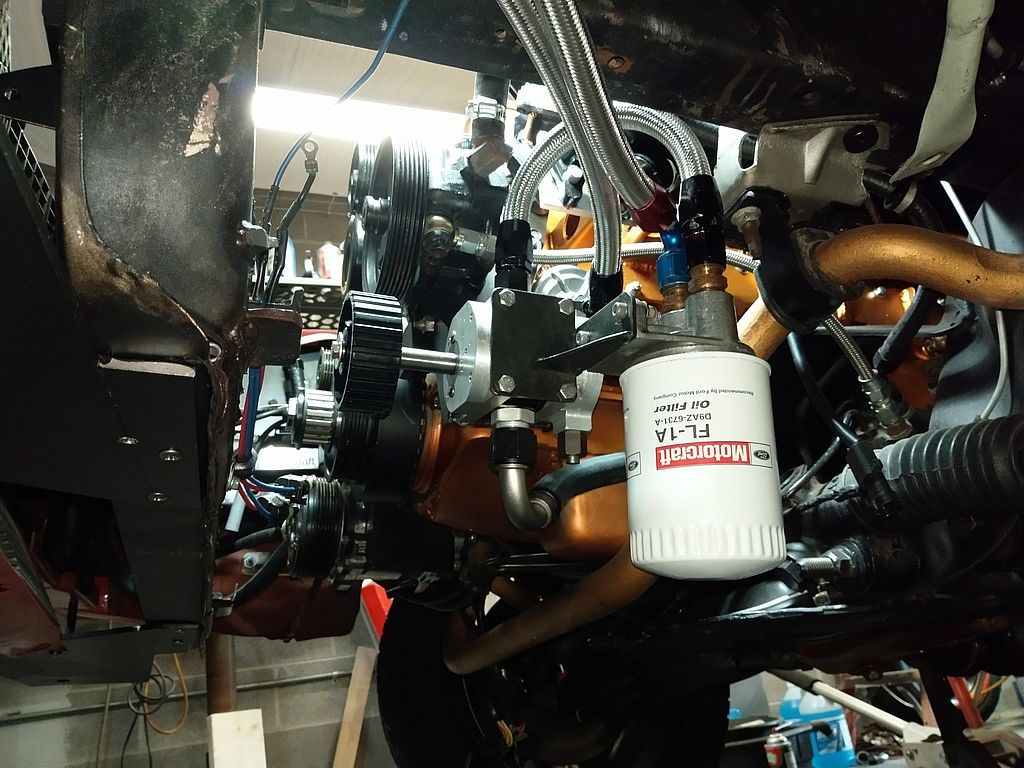

As previously stated, I'm waiting on the Lokar throttle cable. Today I focused on the other things. That had to get done.

More than just bolting the oil pump on here, The lines had to be shortened. Since they no longer had to route around the A2W intercooler that was under the left front fender, the new direct path left them way too long.

I cleaned all of the push rods and rockers, final torqued the head, and loose fitted the stuff together.

Then I removed the drain plugs, just to be sure they were free of any metallic funk.

They were absolutely covered in metallic shavings. They came out of the pan so "hairy", they barely fit through the drain plug hole. I then realized that I had left those damn things in the pan when I took the pan to the machine shop. They ran the pan through their vat to get the paint off. That vat must have all kinds of metal funk floating in the water I'd imagine. I never thought to pull them and look at them while I had the engine apart...

I know that there is nothing in the engine that could have contributed to causing that much funk to be on the drain plug magnets, so it has to be from the machine shop. Nonetheless, I put the hose of my shop vac on each of the three drain plug holes, and let it suck.

I put the plugs back in, and filled the engine with 4.5 qts of non-detergent 30 wt. for my break in...I'll prime that btch with a drill tommorrow.

More than just bolting the oil pump on here, The lines had to be shortened. Since they no longer had to route around the A2W intercooler that was under the left front fender, the new direct path left them way too long.

I cleaned all of the push rods and rockers, final torqued the head, and loose fitted the stuff together.

Then I removed the drain plugs, just to be sure they were free of any metallic funk.

They were absolutely covered in metallic shavings. They came out of the pan so "hairy", they barely fit through the drain plug hole. I then realized that I had left those damn things in the pan when I took the pan to the machine shop. They ran the pan through their vat to get the paint off. That vat must have all kinds of metal funk floating in the water I'd imagine. I never thought to pull them and look at them while I had the engine apart...

I know that there is nothing in the engine that could have contributed to causing that much funk to be on the drain plug magnets, so it has to be from the machine shop. Nonetheless, I put the hose of my shop vac on each of the three drain plug holes, and let it suck.

I put the plugs back in, and filled the engine with 4.5 qts of non-detergent 30 wt. for my break in...I'll prime that btch with a drill tommorrow.

- Status

- Not open for further replies.