Here

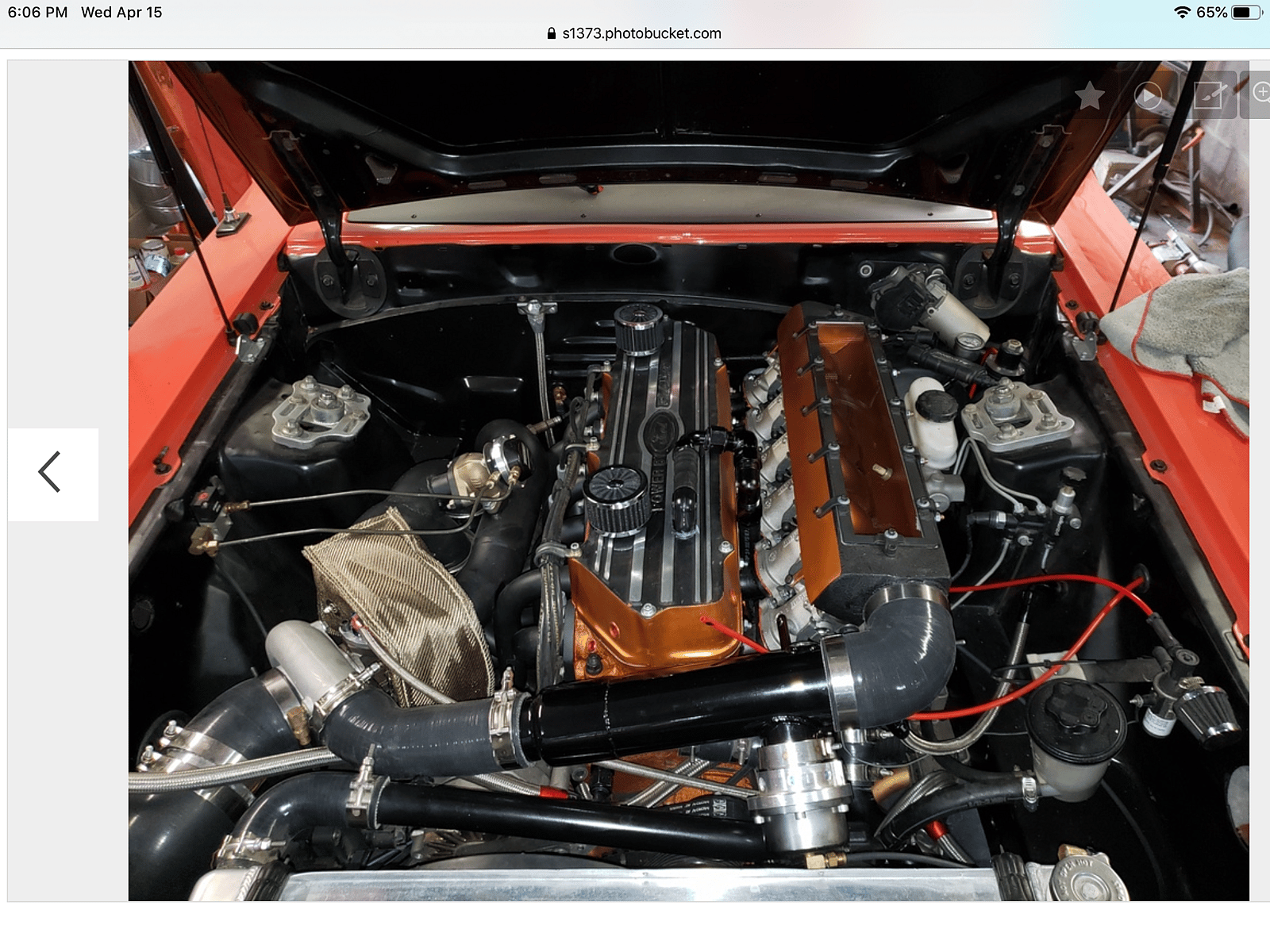

Despite 0 pounds of boost, the first day out with its ITB'S but no longer any turbo and an a91 what? Stevie MegaSquirt tune...

View: https://www.youtube.com/watch?time_continue=34&v=Vb37v0Zb6lA

It smoked its 315s with relative ease in a smoked filled wheelie.

Happy daze Boss.

I don’t know what they call that exhibition in New Zealand,...but here in the United States,.....Smoke, and wheelies don’t go hand in hand..

Matter of fact, considering that video I posted was based on a a NA combo, where a drive-by could barely wake the dead, and was devoid of both smoke, and wheelies.......... I’m calling that stunt a “Lamie”

* Lamies are videos posted of cars barely making 300 WHP, unable to to generate anything remotely exciting to watch that pass the camera at 60 mph or less, on the way to a guaranteed “warning“ ticket, should you be e observed and pulled over by the local PD ( as opposed to a wreckless driving ticket, automatic vehicle impoundment, and a mandatory 24hrs in jail, when you convert it back to forced induction) should you be unlucky enough to have the same situation exist.

Lamies are what you see on any given Saturday night bracket racing event.

Lamies are the feelings that you get after watching any movie with Vin Diesel in it.

Mega Lamies occur when you paid to see the above movie.

Lamies are yellow beer With the word “ lite, or light” on the end.

)

)