- Aug 28, 2017

- 38

- 2

- 8

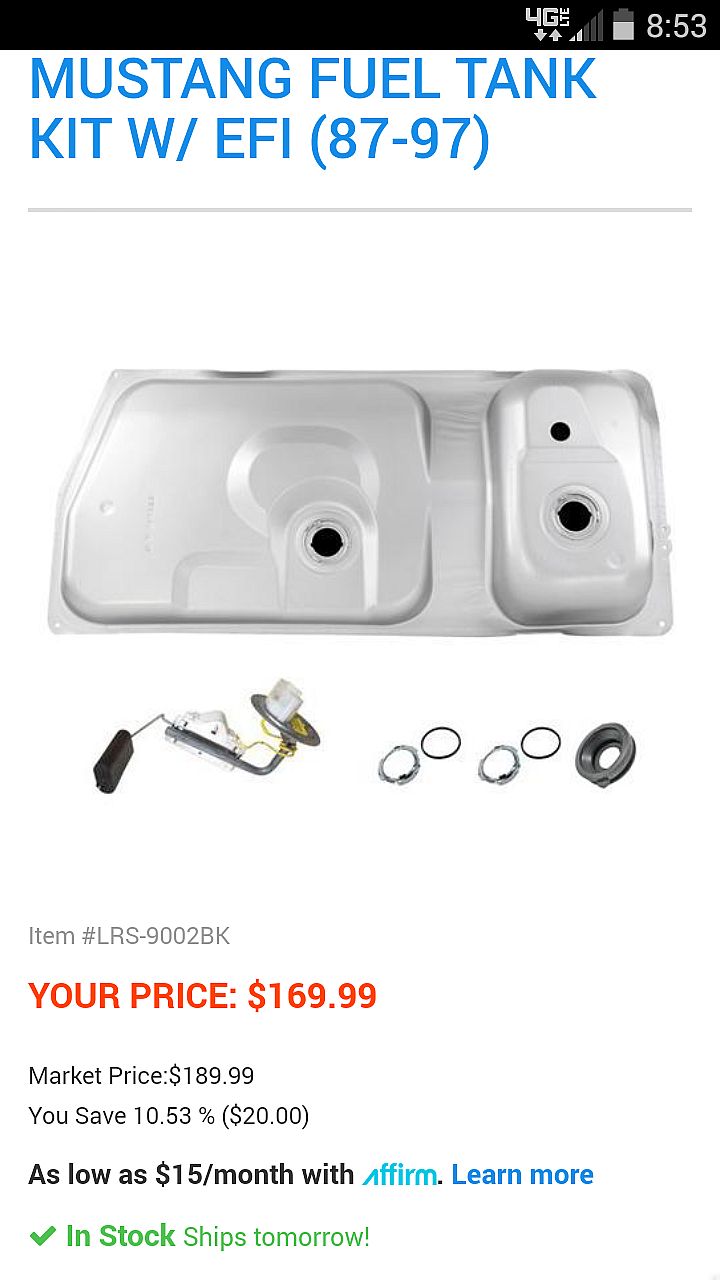

I have some rust and deposits in the tank. Do you think it would be ok to just get as much rest as I can out and reinstall it.No need to drop the tank twice. These pumps are so cheap it really doesn't make a lot of since not to replace it while you have it out.

you shouldn't have any issues for a long time. Fixed correctly the first time. Some folks cut corners and patch things together. Glad to see you went did it right.

you shouldn't have any issues for a long time. Fixed correctly the first time. Some folks cut corners and patch things together. Glad to see you went did it right.