You can assume that really big words strung together in one sentence keep me up at night.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Progress Thread Fire Hazard GT build: On the road

- Thread starter rdharper02

- Start date

-

Sponsors (?)

- May 8, 2006

- 703

- 240

- 84

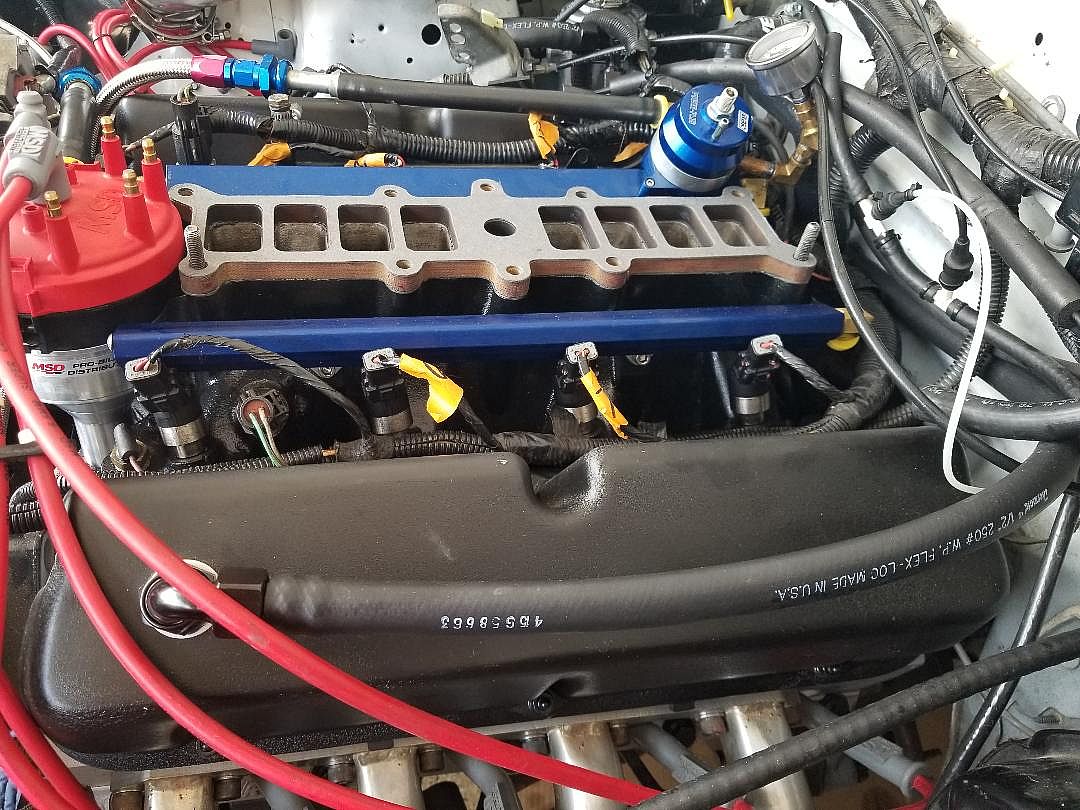

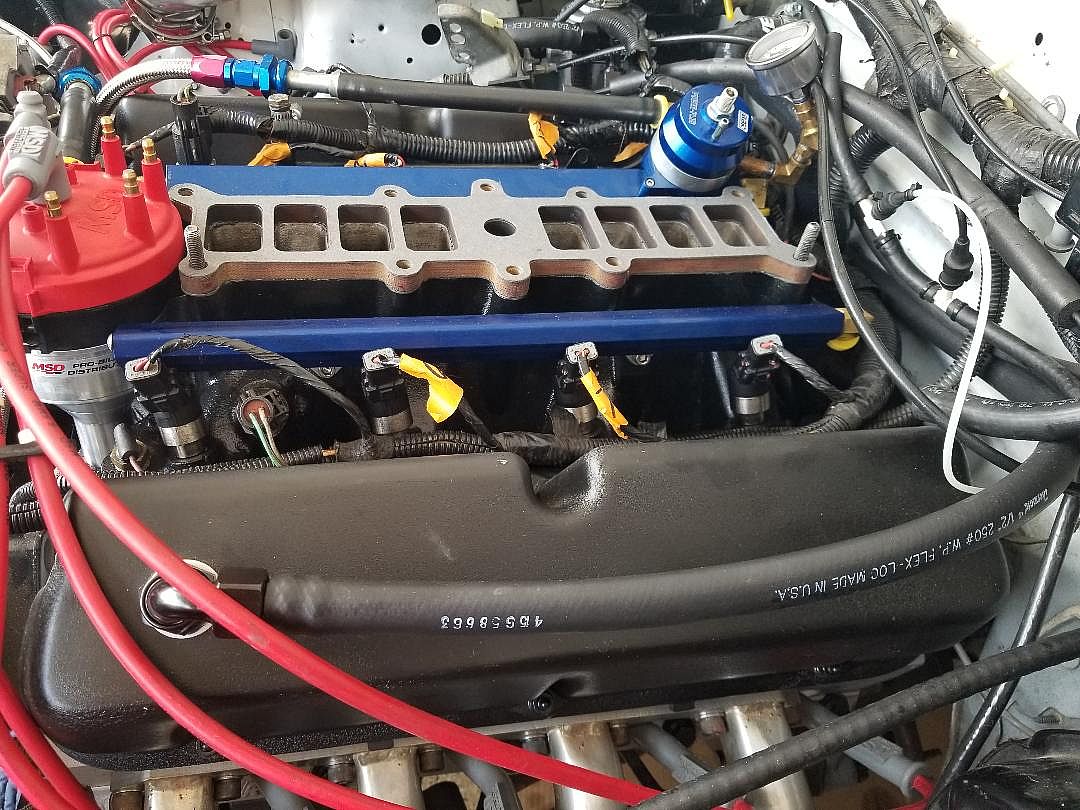

Well here we go again. Extended the fuel rail inlet out, and decided to keep my janky fuel pressure regulator design.

Stood back to admire my hour of work, and decided to throw the upper intake back on.....and ...

The tab contacts the pretty new fuel pressure regulator when you try to hang the other side on the stud. Anyone else have the same problem before? I really do not want to try taking material out of the intake, but the FPR is about 50% larger than the previous one. I can't say anything bad about BBK's stuff, but I'm regretting the move over.

So, I've got three options at this point.

1. Remove the regulator and remount it after setting the intake (but I'll have to remove it again once I go to pull the upper and re-check the valves)

2. Add the BBK FPR to my collection of unused, but new parts, while reusing my old no-name FPR.

3. Getting rid of the BBK rails/FPR and starting over again with Aeromotive pieces.

Hate to spend the money, but I'm truly debating on numero 3.

Stood back to admire my hour of work, and decided to throw the upper intake back on.....and ...

The tab contacts the pretty new fuel pressure regulator when you try to hang the other side on the stud. Anyone else have the same problem before? I really do not want to try taking material out of the intake, but the FPR is about 50% larger than the previous one. I can't say anything bad about BBK's stuff, but I'm regretting the move over.

So, I've got three options at this point.

1. Remove the regulator and remount it after setting the intake (but I'll have to remove it again once I go to pull the upper and re-check the valves)

2. Add the BBK FPR to my collection of unused, but new parts, while reusing my old no-name FPR.

3. Getting rid of the BBK rails/FPR and starting over again with Aeromotive pieces.

Hate to spend the money, but I'm truly debating on numero 3.

- May 8, 2006

- 703

- 240

- 84

Well, guess I've taken a bit of time off. Got back at it the other day with the help of my Dad. We managed to get everything buttoned up and attempted to fire only to lack the sweet sound of the fuel pump building pressure. Now that pump, though 5 years old, is an aeromotive 340 pump with exactly zero miles on it. So my logical thought is that something in the chain prior to the pump is bad. Got to thank Jricker's checklist here. Managed to get all the way back to the inertia switch before finally admitting defeat to my Dad and resorting to (his initial thought) dropping the tank and checking the pump. Now the tank had been drained for storage, so there shouldn't be any problems right?

Last edited:

What’s that...a fossilized a 340? Call the Smithsonian...Maybe they‘ll put it an exhibit.

Right next to a Velociraptor tooth.

A near perfect specimen from the Gastankious Notdrainious era...

How freakin rare.

Right next to a Velociraptor tooth.

A near perfect specimen from the Gastankious Notdrainious era...

How freakin rare.

Last edited:

- May 8, 2006

- 703

- 240

- 84

Agreed. I spent a day driving around getting a new tank and an Accel pump. Then had the joy to find everything installed worked, but the sealant at the fuel rails. It's been a couple of years, but I know I asked if the stuff was fuel safe. Guess not. We reset all the fittings and lines, went to fire again, and seemed to have no fuel still. A couple hours of testing showed seven dirty 42lb injectors and one which completely refused to do the one thing it was made for...open and close. Decided to give Summit $450 to ship some EV1 42lbs injectors "next day." only to find the term "next" to be negotiable in the time of COVID.

- May 8, 2006

- 703

- 240

- 84

So I've got to give Summit credit, the Holley injectors came on time.

Popped them in after ensuring each fuel rail union had been cleaned and (now) properly sealed with fuel safe goo. Bolted the upper and all components in, set to TDC and number 1 on the distributor, and fired it up after about two rotations. Awesome....right. Shut it off to let it cool and put the 6al-2 back into the mix. Go to fire.....no start. Disconnect 6al-2, and plug directly to the coil....no start...…..WTH. So it's time for input from the masses. I appear to have fuel, spark, and tested the below.

-TFI is sending signal to the coil

-Coil is firing (might be the next choice for blind replacement)

-I have spark at the plugs

-When cranked, I can pull the plugs and confirm they are seeing fuel

-Cleaned and verified every ground connection from the rear mounted battery to the engine (batt- 0 cable - bulkhead - engine - firewall/engine)

-Key on test just gave me the evap (removed)

- Did notice my new MSD dist seemed awfully warm after running (higher temp than the block).

Popped them in after ensuring each fuel rail union had been cleaned and (now) properly sealed with fuel safe goo. Bolted the upper and all components in, set to TDC and number 1 on the distributor, and fired it up after about two rotations. Awesome....right. Shut it off to let it cool and put the 6al-2 back into the mix. Go to fire.....no start. Disconnect 6al-2, and plug directly to the coil....no start...…..WTH. So it's time for input from the masses. I appear to have fuel, spark, and tested the below.

-TFI is sending signal to the coil

-Coil is firing (might be the next choice for blind replacement)

-I have spark at the plugs

-When cranked, I can pull the plugs and confirm they are seeing fuel

-Cleaned and verified every ground connection from the rear mounted battery to the engine (batt- 0 cable - bulkhead - engine - firewall/engine)

-Key on test just gave me the evap (removed)

- Did notice my new MSD dist seemed awfully warm after running (higher temp than the block).

Last edited:

- May 8, 2006

- 703

- 240

- 84

Nothing? Well replaced the MSD Coil and rebuilt the starter today as it was dragging. Still no luck. Any input????

Sorry RD... i’m worthless when it comes to diagnosing a no start.Nothing? Well replaced the MSD Coil and rebuilt the starter today as it was dragging. Still no luck. Any input????

- May 8, 2006

- 703

- 240

- 84

I'm not doing much better Mike. At this point I'm throwing mud at a wall. Next step, new distributor, to replace the barely used MSD sitting in it.

I’m not at the point of needing one (I hope) but what is the problem with all the aftermarket distributors? I read so many threads about having issues with them, and everyone recommending going back to OE.

Why can’t anybody make good parts? (Now back to our originally scheduled program)

Why can’t anybody make good parts? (Now back to our originally scheduled program)

- May 8, 2006

- 703

- 240

- 84

I'm running the MSD TFI that came on the pro-billet distributor. Well, until I find that it's the problem and the new distributor (that cost 1/4 of the amount) shows me it works.Corrosion is usually the at fault for the MSD, Are you running a factory/stock Tfi?

- May 8, 2006

- 703

- 240

- 84

So we picked up a Spectra distributor from the local parts store, and checked/cleaned every ground I have. The spectra is actually not as pretty as the pro-billet, but seems to have less play in it. After all was installed....still no worky. Figured I have fuel and spark, so it has to be a timing event. Oddly found number 5 to have almost no compression. Puled the upper intake and valve covers and am not happy with the rocker adjuster nuts. Regardless of the girdle, every one of them looks like the bottom thread is pulled out. So, some new dart adjusters are on order.

Question for the forum: Is it the camshaft or crankshaft that ultimately determines firing order?

Question for the forum: Is it the camshaft or crankshaft that ultimately determines firing order?

- May 8, 2006

- 703

- 240

- 84

I've been told it's just the camshaft that changed for the HO firing order, but have been unable to verify it 100%. When the 327 (331 with factory bore) decided to wash a cylinder we found soft spots in the crank. Knowing I'm limited by my factory block, I decided to stick a refinished 302 crank into it. I believe it was an 85, but for the life of me can't remember. The rocker adjusters should be in by Monday, so I should be able to determine if the adjustment was causing the problems. If not, it's got to be the computer.

It’s the cam.

You can put two different cams in a SBF. One will have a standard 302 firing order, the other can be a 351w based firing order.

They are known as the 302 and the 351 firing orders and are based on which camshaft you are using. The 302 firing order is 1-5-4-2-6-3-7-8 and the 351 order is 1-3-7-2-6-5-4-8. ... The firing order for a Ford 302 motor is essential knowledge when building, rebuilding, or maintaining your Fox Body or SN-95 Mustang.

The crank is still the same.

One of two things here. First....our Boy from Iowa bumped his head for a week trying to start his engine. He checked and verified all the things you have, and still no cranky.

It turned out to be valve adjustment. He had over tightened his valve adjustment, and the valves were never fully closing.

Secondly. Verify your firing order. if you have wires on wrong, that sht ain’t gon start either.

You can put two different cams in a SBF. One will have a standard 302 firing order, the other can be a 351w based firing order.

They are known as the 302 and the 351 firing orders and are based on which camshaft you are using. The 302 firing order is 1-5-4-2-6-3-7-8 and the 351 order is 1-3-7-2-6-5-4-8. ... The firing order for a Ford 302 motor is essential knowledge when building, rebuilding, or maintaining your Fox Body or SN-95 Mustang.

The crank is still the same.

One of two things here. First....our Boy from Iowa bumped his head for a week trying to start his engine. He checked and verified all the things you have, and still no cranky.

It turned out to be valve adjustment. He had over tightened his valve adjustment, and the valves were never fully closing.

Secondly. Verify your firing order. if you have wires on wrong, that sht ain’t gon start either.

- May 8, 2006

- 703

- 240

- 84

At this point I'm seriously in belief of the valves being incorrectly set. We found at least one cylinder down on compression before my gauge called it quits. After a quick adjustment it was able to build enough to blow a finger away from the plug hole. About every one of my adjusters seems to have the bottom thread pulled out of it, which is even stranger with the girdle securing them. I've played the "we've got 7 in stock" game with the big box parts stores and have 16 coming in today. Got to love the next day upcharge on Saturday.

- May 8, 2006

- 703

- 240

- 84

Similar threads

- Replies

- 25

- Views

- 1K

- Replies

- 28

- Views

- 3K

- Replies

- 26

- Views

- 2K

Progress Thread

2.3L - crank no start issue. Has spark, fuel, good compression.

- Replies

- 199

- Views

- 15K

- Replies

- 6

- Views

- 1K