Cable tension problems are marked by difficulty in getting the transmission into gear from a full stop into first or reverse. If that is not your problem, the transmission is the culprit.

Clutch Adjustment for stock and aftermarket setups

Revised 28-Apr-2016 to include need for longer cable with single hook quadrant

Clutch adjustment with stock cable and quadrant

There is a self-adjusting mechanism for the clutch cable. As the clutch wears the cable tension changes, that is why there is a self-adjusting mechanism built into the clutch pedal. On the clutch pedal there is a toothed plastic quadrant with a ratchet pawl that engages the quadrant. As you pull up on the clutch pedal, it ratchets and takes any slack out of the clutch cable. Mess around with the pedal or even bump it while the end that fits in the clutch fork is loose, and it tries to take up the slack in the cable. That has the effect of shortening the cable.

Do the clutch adjustment first before considering any other problems. With the stock plastic quadrant and cable, pull up on the clutch pedal until it comes upward toward you. It will make a ratcheting sound as the self-adjuster works. To release to tension of the stock quadrant, use a screwdriver to lift the ratchet paw up and out of engagement with the quadrant teeth.

You can use a screwdriver to lift the ratchet pawl off the quadrant teeth. That will allow you to move the quadrant to allow more slack in the cable. If the cable is too loose, pull up on the pedal. The ratchet pawl will allow the quadrant to take up the slack in the cable and lock the adjustment.

The following applies to aftermarket clutch cables and quadrants.

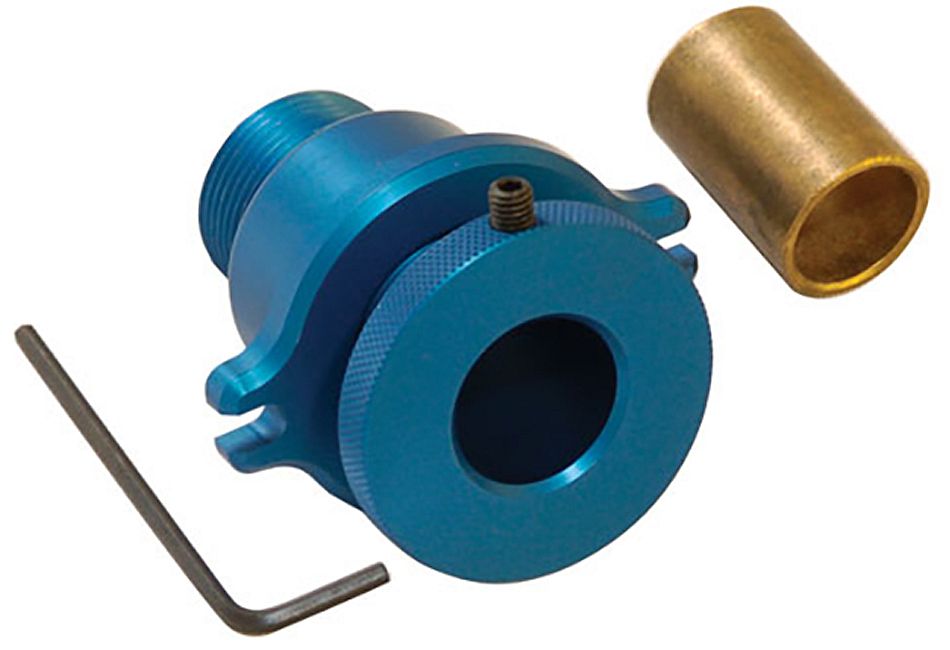

Adjustable cables are used when the plastic quadrant is replaced with an aftermarket metal quadrant. The downside to this setup is that you have to get under the car to adjust the clutch. Add a firewall adjuster to an adjustable cable setup and you can spare yourself from getting back under the car to make any fine adjustment that you desire.

The fancy 2 and 3 hook quadrants are for use with stock length cable and a firewall adjuster. Use the firewall adjuster and screw in and out to take the slack out of the cable and get the clutch engagement point just where you want it.

Binding clutch cable

A binding clutch cable will make the clutch very stiff. If the cable is misrouted or has gotten too close to the exhaust, it will definitely bind. The binding common to adjustable cables is often due to misplacement of the adjusting nuts on the fork end of the cable. This will also cause the cable to wear and fray. Both nuts should be on the back side of the fork so that the domed nut faces the fork and the other nut serves as jam or locknut to the domed nut.

Clutch pedal adjustment

Clutch pedal adjustment with aftermarket quadrant and cable: I like to have the clutch completely disengaged and still have about 1.5” travel left before the pedal hits the floor. This means that I have only about 1” of free play at the top before the pedal starts to disengage the clutch. Keep in mind that these figures are all approximate. When properly adjusted, there will not be any slack in the clutch cable.

You will have 4-15 lbs. preload on the clutch cable. With a non-adjustable cable and a firewall adjuster, the cable needs to go in the second hook of the quadrant. Single hook quadrants used with a firewall adjuster may make the clutch too tight, causing it to slip. The possible exception to this is the Maximum Motorsports cable which is a bit longer to make it work with a single hook quadrant.

Adjustable clutch cable tips:

Loosening the cable adjustment nut (throwout bearing arm moves to the rear of the car) moves the disengagement point towards the floor.

Tightening the cable adjustment nut (throwout bearing arm moves to the front of the car) moves the disengagement point towards the top of the pedal.

Firewall adjuster tips

Turning the firewall adjuster IN makes the engagement point closer to the floor since it loosens the cable. You have to push the pedal to the floor to disengage the clutch. Too loose a cable and the clutch won't completely disengage and shifting will be difficult. Gears will grind and you may have difficulty getting the transmission in first gear when stopped.

Turning the firewall adjuster OUT makes the engagement point farther from the floor since it tightens the cable. You push a short distance to disengage the clutch. Too tight a cable will cause clutch slippage.

Aftermarket solutions to the problem:

The quadrant needs to be replaced if you use any type of aftermarket cable or adjuster. My preference is a Ford Racing quadrant, adjustable cable and Steeda firewall adjuster. The adjustable Ford Racing cable is just as good as the stock OEM cable. It allows a greater range of adjustment than a stock cable with a aftermarket quadrant and firewall adjuster. Combined with the Steeda adjuster, it lets you set the initial cable preload and then fine tune the clutch engagement point to your liking without getting under the car.

Using a stock OEM cable, firewall adjuster and a single hook quadrant may result in not having any free pedal travel before the clutch starts to disengage. I found this out the hard way.

See

Summit Racing - High Performance Car and Truck Parts l 800-230-3030 for the following parts.

Ford Racing M-7553-B302 - Ford Racing V-8 Mustang Adjustable Clutch Linkage Kits - Overview - SummitRacing.com Cable and quadrant assembly $90

The Ford Racing Adjustable cable is available as a separate part:

Clutch Cable, Adjustable, Ford, Mercury, 5.0L, Kit

[url=http://www.summitracing.com/parts/SDA-555-7021/]Steeda Autosports 555-7021 - Steeda Autosports Firewall Cable Adjusters - Overview - SummitRacing.com Steeda firewall adjuster. $40

Fix for the quadrant end of the cable popping out of the quadrant when installing a replacement cable courtesy of

Grabbin' Asphalt

Help for those who have replaced the clutch assembly and are still having problems with adjustment:

The next step doesn't make much sense it you already have the transmission installed, but just for sake of discussion, here it is:

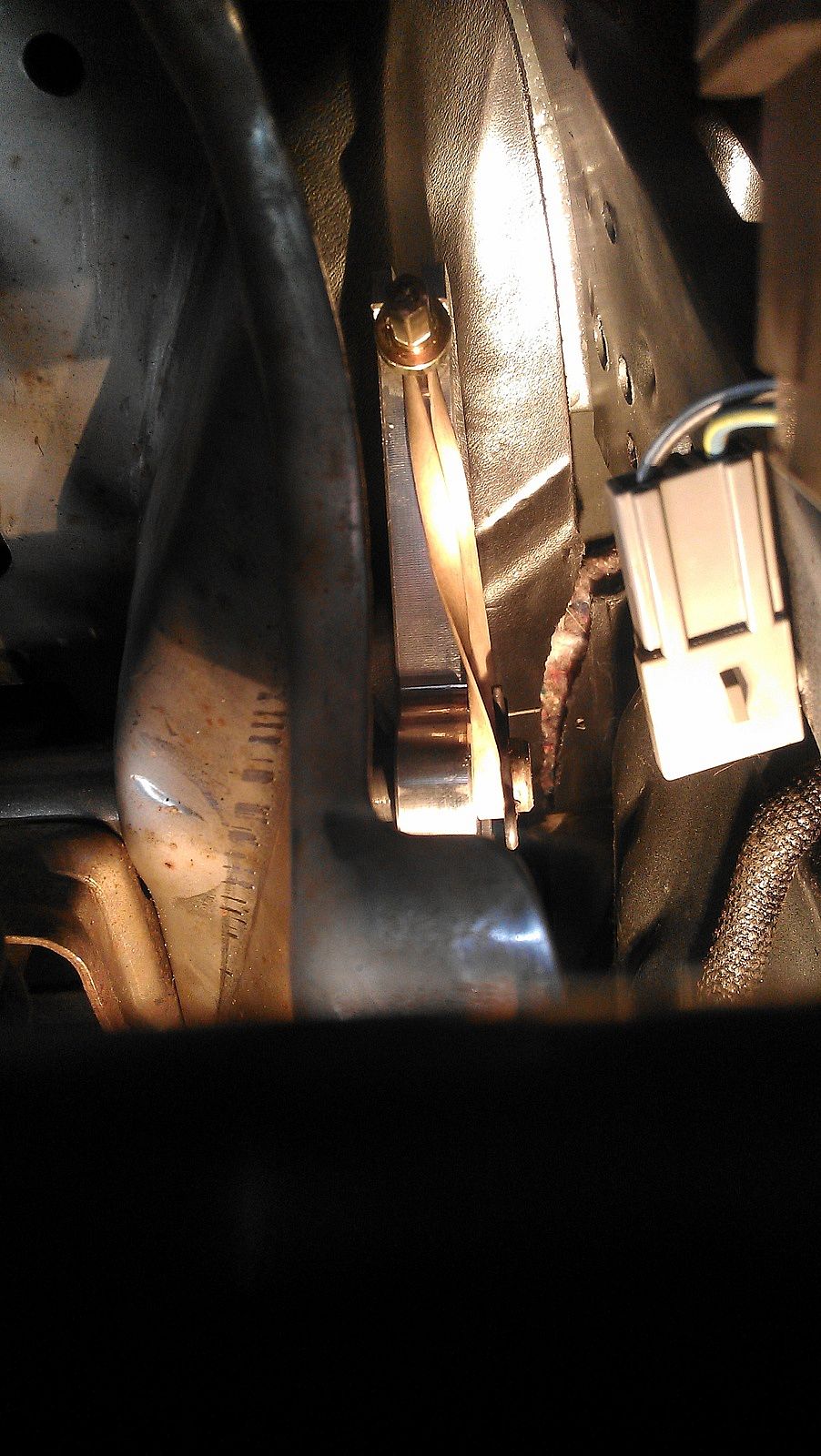

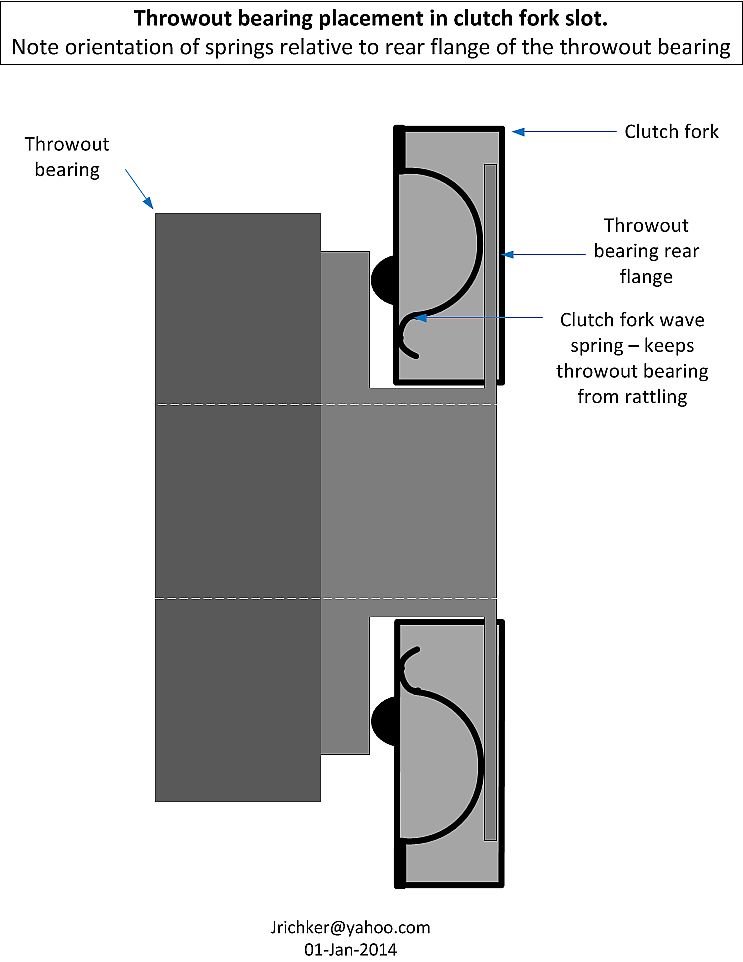

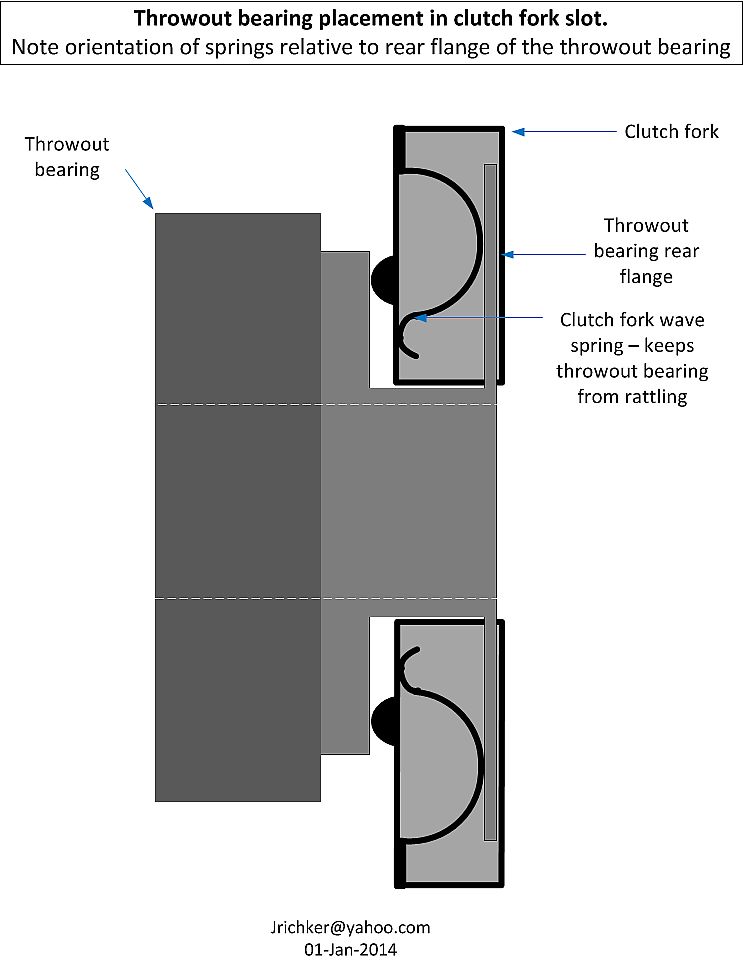

The throwout bearing sits in the clutch fork arm with the wave springs pressing on the rear flange of the throwout bearing.

Major differences between the distance between the flywheel surface and the clutch fingers may require tinkering with the clutch fork pivot ball. Stack your old pressure plate, clutch disc and flywheel up like they were when installed in the car. Tighten down all the pressure plate bolts and measure the distance between the clutch fingertips and the flywheel face.

Too much thickness will cause the clutch fork arm to sit too far back to get the clutch cable on the quadrant. It may even sit against the rear or the bell housing hole for the clutch fork arm. In that case, reduce the pivot ball height.

Too little thickness will cause the clutch fork arm to sit too far forward and bottom out against the front side of the bell housing hole for the clutch fork arm.. This will prevent the clutch from fully disengaging.

In other words, the clutch fork arm should sit positioned midway or a little towards the rear in the bell housing hole for the clutch fork arm when the cable is properly tensioned.