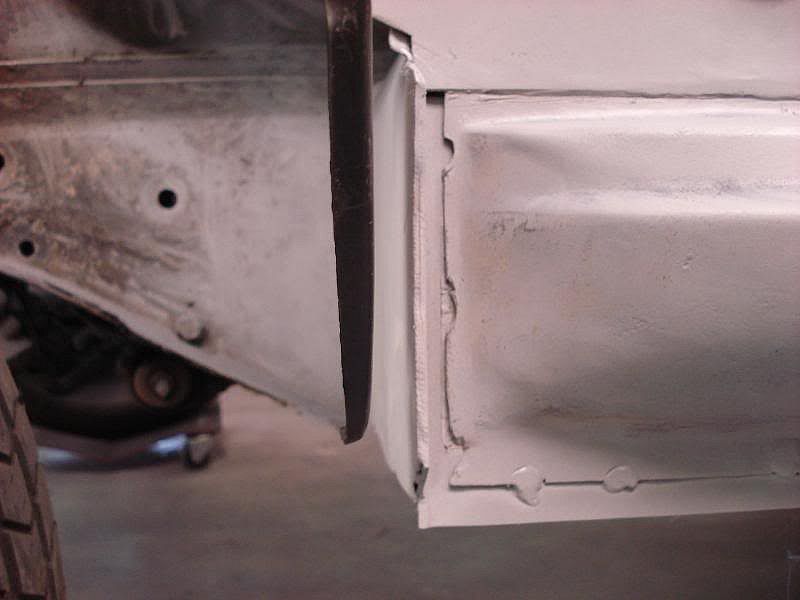

Anybody have a picture of what the rear splash guard on the fender of a 65 vert should look like mounted? I thought the front was flush with the firewall extension but that leaves a gap of about an inch from the torque box at the bottom. I'll put some pics up later, it's a repop piece so that mat be part of the problem, either that or it's mounted further back but that isn't my recollection. Mine was half rotted off when I got to it so that didn't help