I hope to get some expert help (i.e.@jrichker).

I did a TFS1 cam upgrade & fox body EFI swap (X3Z PCM) in my 1966 Mustang with a C4. The car is hard to start. It initiaruns while cranking, but almost immediately dies with the key in the run position until it begins to warm up. Then it idles okay...Not great, and it won't rev up. It stumbles with no acceleration when opening the throttle in neutral or drive. It pops in the intake as if it is going lean. WOT does nothing but bog down. If I let off the throttle it barely accelerates when the throttle is almost closed.

The harness is from a 1991 5-speed and the EGR, air injection & canister purge emissions wiring was removed from the harness. No VSS or clutch safety switch are present.

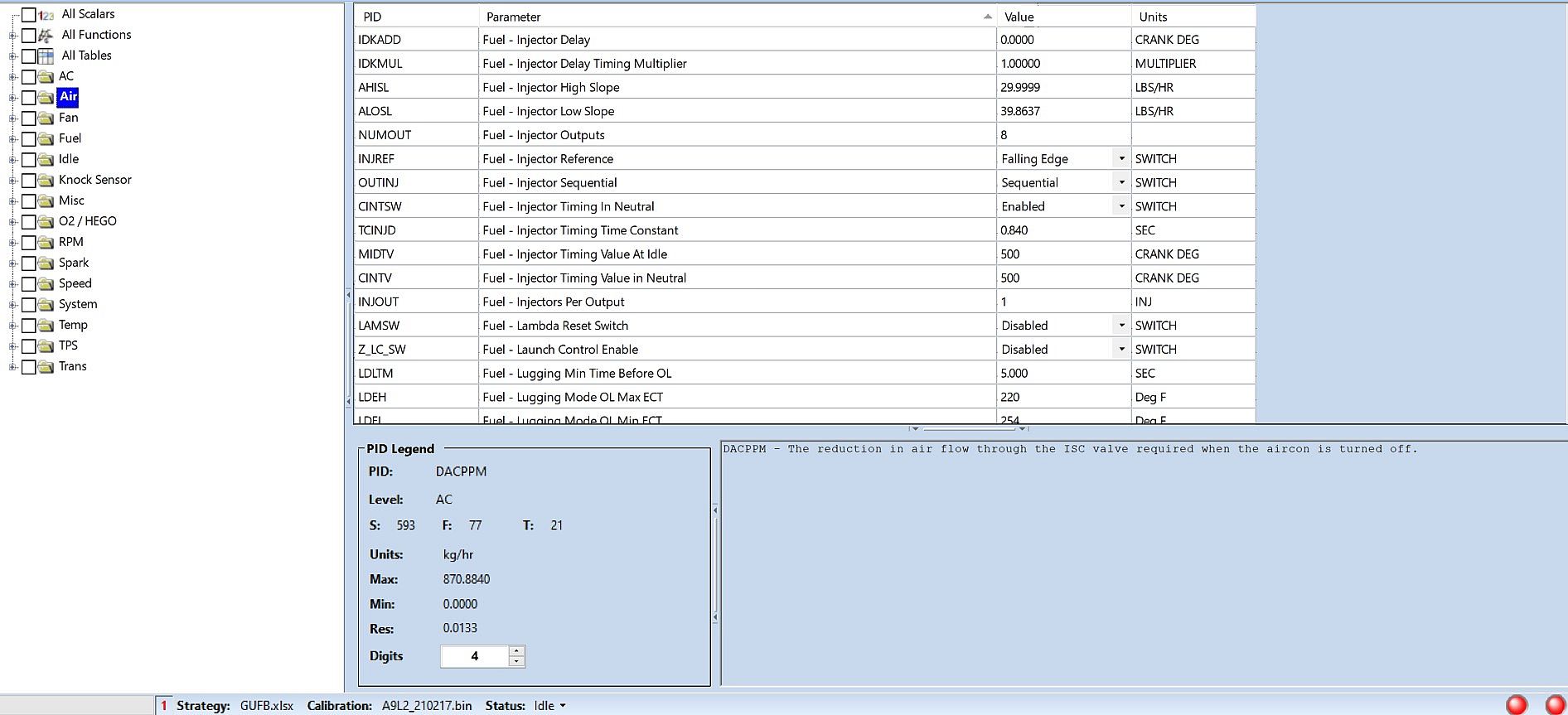

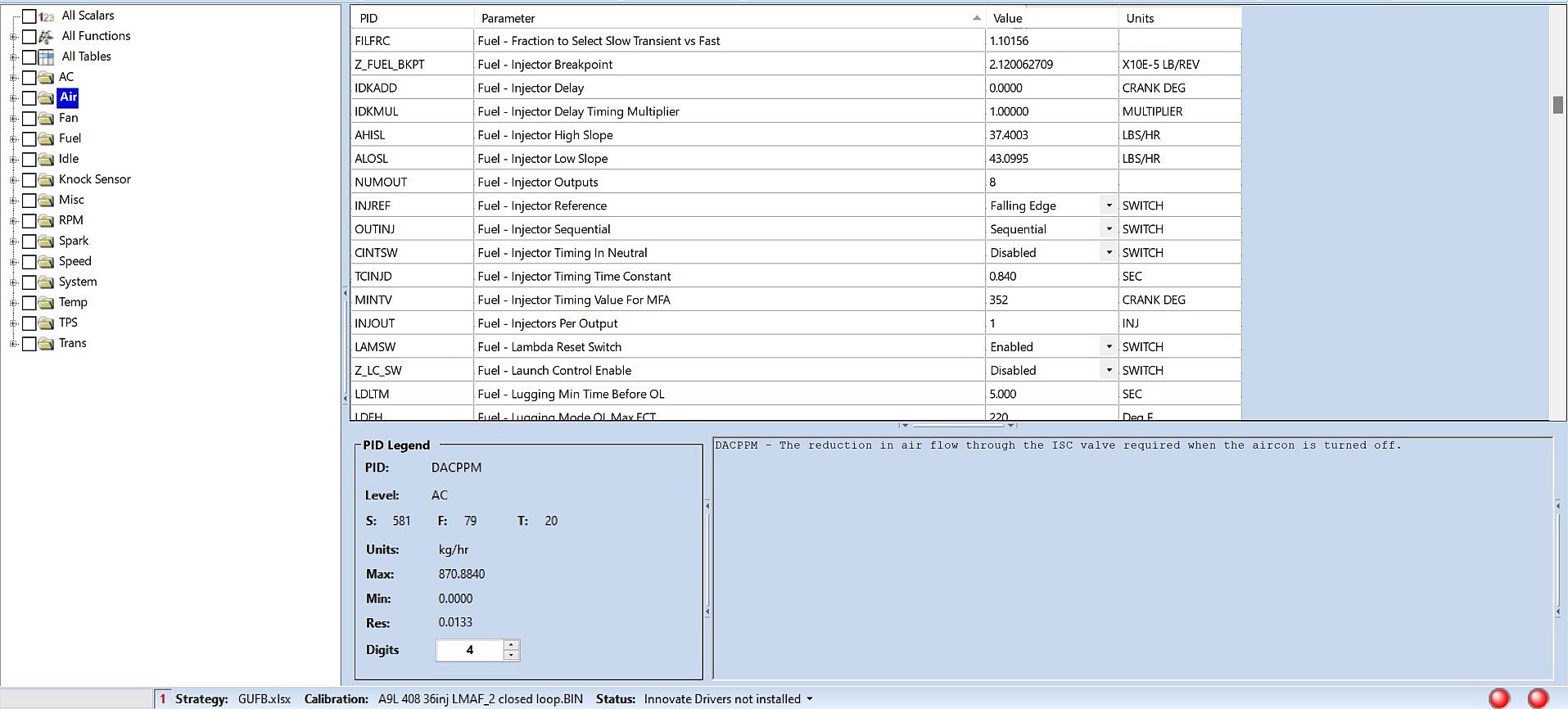

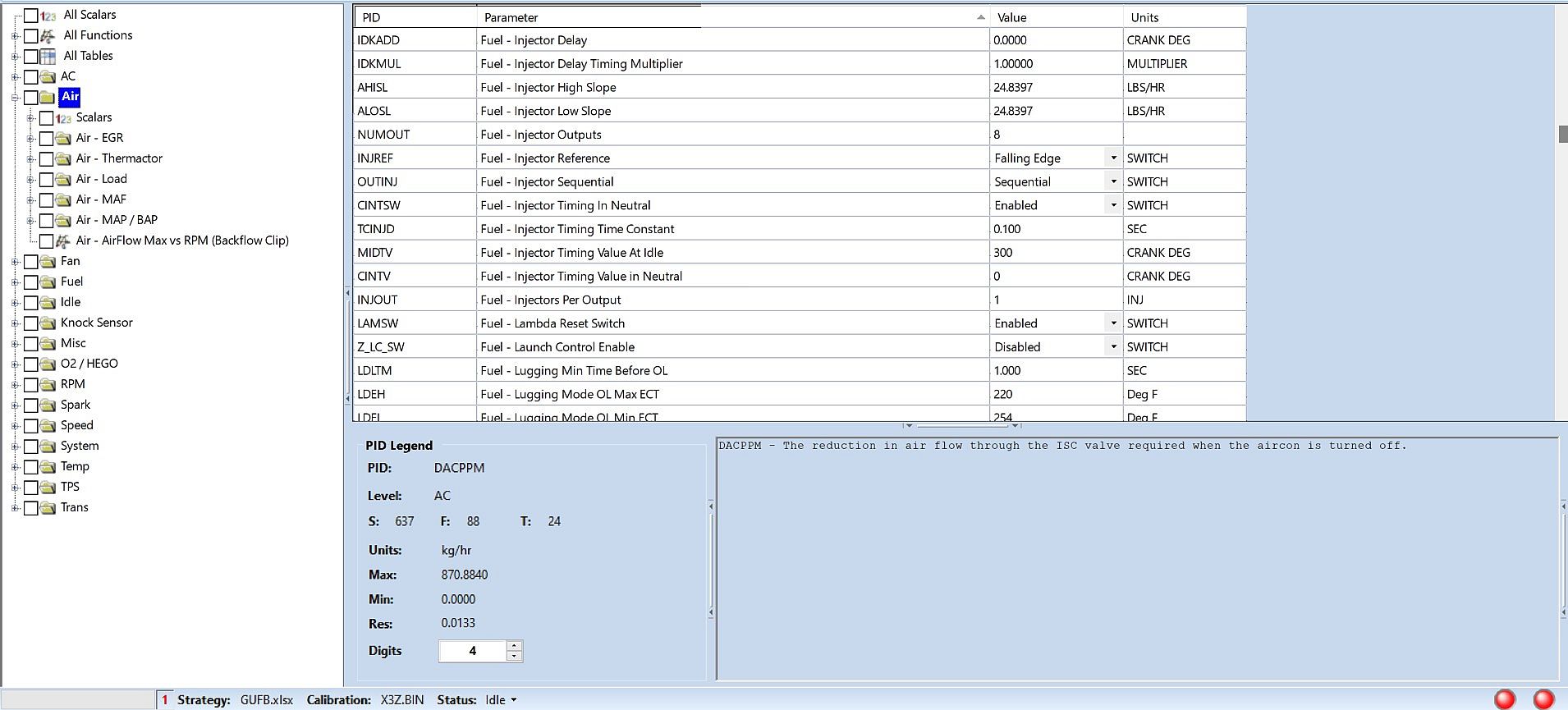

I did the cam & EFI together on an otherwise good running motor. The engine is a '99 Explorer 5.0L short block, ported 351W D0OE heads (Autolite 45 spark plugs), 1.7 rockers, 1993 Cobra 70mm MAF, 24lb injectors, 65mm Explorer TB with fox TPS & IAC, ported Explorer lower & GT-40 Lightning tubular upper intake manifold. External F150 fuel pump (1988-ish style).

This PCM has been stored on the shelf the past 17 years. Initially this new-to-me X3Z PCM had a burnt trace on pin 46. I soldered in a jumper. The capacitors appeared good (no leaks/corrosion) when I recently looked at them.

Fuel pressure is mid forties & jumps to about 50 psi when the regulator's vacuum line is unplugged. The fuel rail & regulator are from a mid-1990s F150, so the pressure is a bit higher than a Foxbody. The pump & filter are new. I tried pinching off the return to rule out the pump with no throttle improvement.

No abnormal KOEO codes, good fuel pressure, base timing 12°, no apparent vacuum leaks, new spark plugs, & I did a base idle reset after verifying TPS voltage was in spec. The IAC motor was cleaned and is working.

I swapped the TPS, ACT, and barometer sensor with used spares without improvement.

I unplugged the MAF without a change. I removed the K&N air filter and idle slightly increased (maybe 75 RPM), but is still rough. I cleaned the MAF. It still won't rev up.

I tried an A9L & 55mm MAF (without swapping back to 19lb injectors) and it ran much better. Not ideal, but it revved in neutral and idled well from a cold start. Is this X3Z computer not working? Are there any specific tests that I should do?

I did a TFS1 cam upgrade & fox body EFI swap (X3Z PCM) in my 1966 Mustang with a C4. The car is hard to start. It initiaruns while cranking, but almost immediately dies with the key in the run position until it begins to warm up. Then it idles okay...Not great, and it won't rev up. It stumbles with no acceleration when opening the throttle in neutral or drive. It pops in the intake as if it is going lean. WOT does nothing but bog down. If I let off the throttle it barely accelerates when the throttle is almost closed.

The harness is from a 1991 5-speed and the EGR, air injection & canister purge emissions wiring was removed from the harness. No VSS or clutch safety switch are present.

I did the cam & EFI together on an otherwise good running motor. The engine is a '99 Explorer 5.0L short block, ported 351W D0OE heads (Autolite 45 spark plugs), 1.7 rockers, 1993 Cobra 70mm MAF, 24lb injectors, 65mm Explorer TB with fox TPS & IAC, ported Explorer lower & GT-40 Lightning tubular upper intake manifold. External F150 fuel pump (1988-ish style).

This PCM has been stored on the shelf the past 17 years. Initially this new-to-me X3Z PCM had a burnt trace on pin 46. I soldered in a jumper. The capacitors appeared good (no leaks/corrosion) when I recently looked at them.

Fuel pressure is mid forties & jumps to about 50 psi when the regulator's vacuum line is unplugged. The fuel rail & regulator are from a mid-1990s F150, so the pressure is a bit higher than a Foxbody. The pump & filter are new. I tried pinching off the return to rule out the pump with no throttle improvement.

No abnormal KOEO codes, good fuel pressure, base timing 12°, no apparent vacuum leaks, new spark plugs, & I did a base idle reset after verifying TPS voltage was in spec. The IAC motor was cleaned and is working.

I swapped the TPS, ACT, and barometer sensor with used spares without improvement.

I unplugged the MAF without a change. I removed the K&N air filter and idle slightly increased (maybe 75 RPM), but is still rough. I cleaned the MAF. It still won't rev up.

I tried an A9L & 55mm MAF (without swapping back to 19lb injectors) and it ran much better. Not ideal, but it revved in neutral and idled well from a cold start. Is this X3Z computer not working? Are there any specific tests that I should do?