Very crude example. I plan to take my sweet time with my dremel to make it happen.

Very crude example. I plan to take my sweet time with my dremel to make it happen.

That finger is the voice of reason.....pay heed.You can tae that finger and put it in one of your oil leaks.

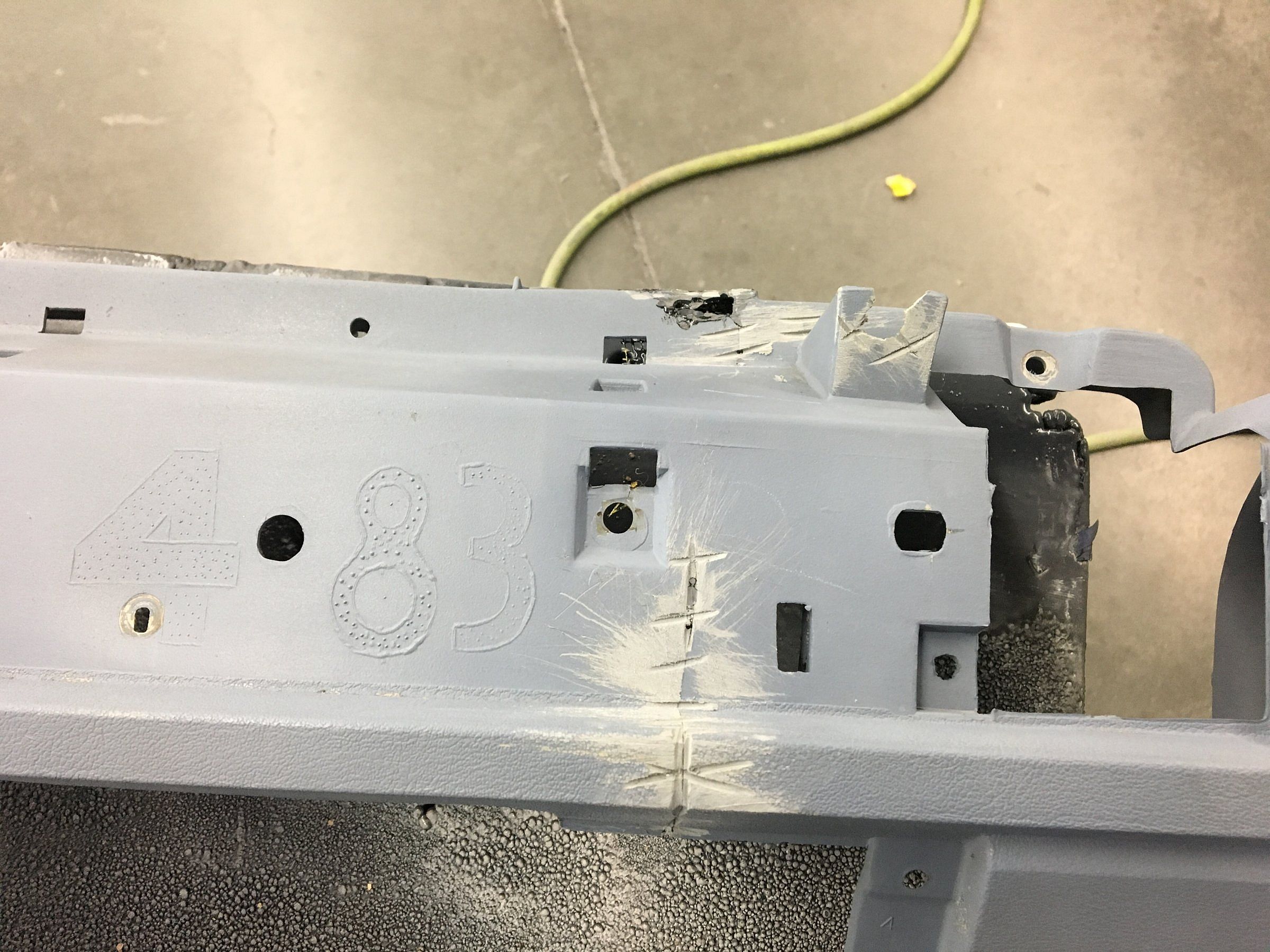

I was thinking that the cutline bonded directly beneath the body side molding up higher.Here is what I am up against there, though. I do not want to glue it to the flat face of the bumper trim line. I want to go under that, and that part of the bumper isnt flat. It is at an angle where the two mating surfaces would not sit snugly against each other as if I were gluing it to the face of the trim like others before me with LX bumpers. My plan was to "hang" it under there, and fill the void between the two surfaces with said bonding adhesive. So the adhesive is still in the equation, its just not the sole thing holding the bumpers together, because the two surfaces do not jive just right.

See the angles up under there on the front face? Its not just a 90 degree flat spot to glue to under there. Now the side will glue fine under the trim, but that front face is a bit tricky with what I am trying to accomplish.

I was thinking that the cutline bonded directly beneath the body side molding up higher.

I'm mildly amused that you used a picture of a die cast model to illustrate your point.Here is what I am up against there, though. I do not want to glue it to the flat face of the bumper trim line. I want to go under that, and that part of the bumper isnt flat. It is at an angle where the two mating surfaces would not sit snugly against each other as if I were gluing it to the face of the trim like others before me with LX bumpers. My plan was to "hang" it under there, and fill the void between the two surfaces with said bonding adhesive. So the adhesive is still in the equation, its just not the sole thing holding the bumpers together, because the two surfaces do not jive just right.

See the angles up under there on the front face? Its not just a 90 degree flat spot to glue to under there. Now the side will glue fine under the trim, but that front face is a bit tricky with what I am trying to accomplish.

I'm mildly amused that you used a picture of a die cast model to illustrate your point.

Let's get mach to this one...