So i bought a pack and it arrived this morning.

Couple questions.

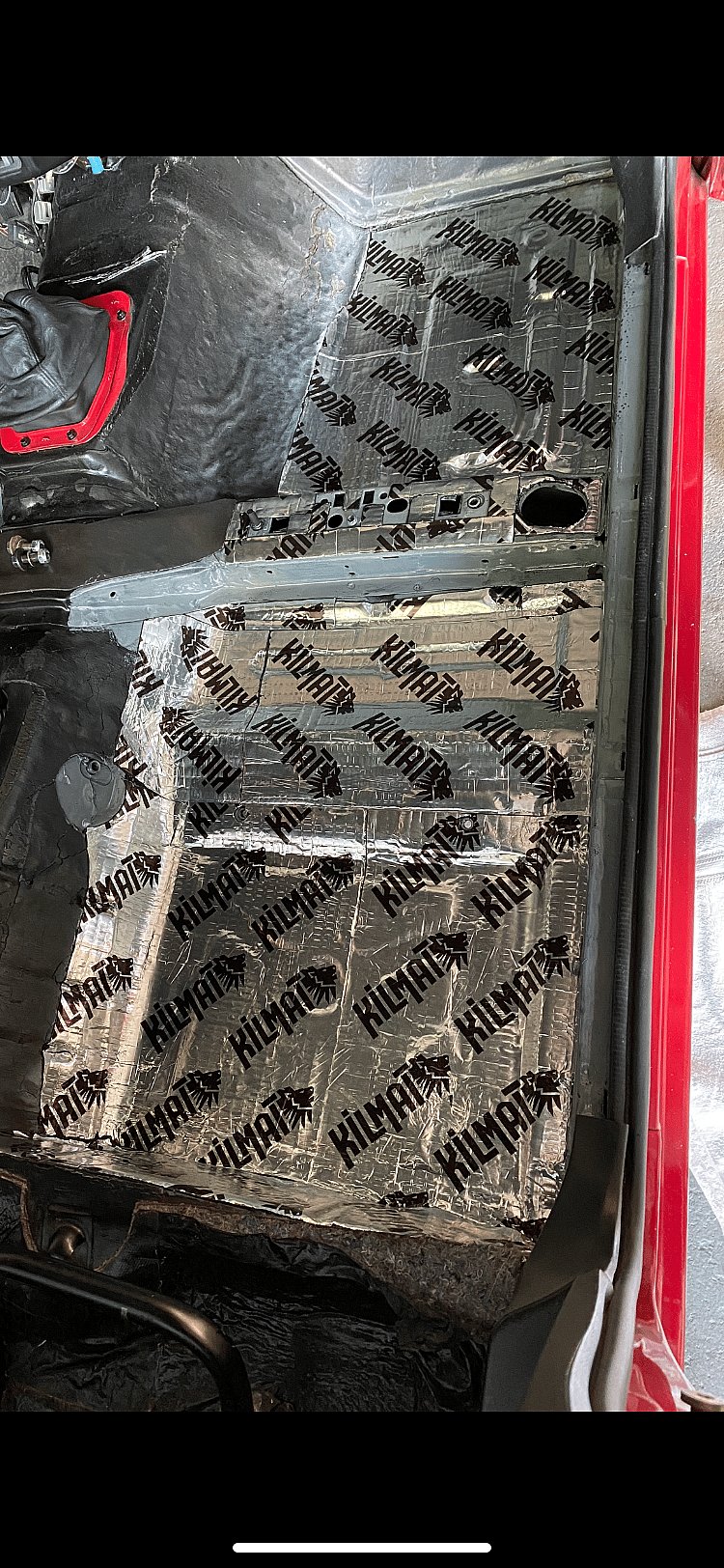

I did the spare tire well, which was a bit of a pain, maybe that's not the place i should have started, but it got easier as i moved along to flat spots.

Is there a preferred method to lay this stuff?

Are you guys cutting to fit?

Laying and cutting and pulling up the excess?

Overlapping? I didn't do it much, but am i'm obsessing for no reason? The stuff is thinner than i expected, so a little overlap, doesn't seem that bad.

Next question, rear quarter wheel wells, i never realized how open it was.

I bet there is a serious amount of sound coming through there.

Is there something to fill it with?

Almost seems like a place that should be filled with Rockwool or similar.