Tim65GT

Active Member

I wish I had the patience for all that sanding. Fiberglass is cool for custom work.

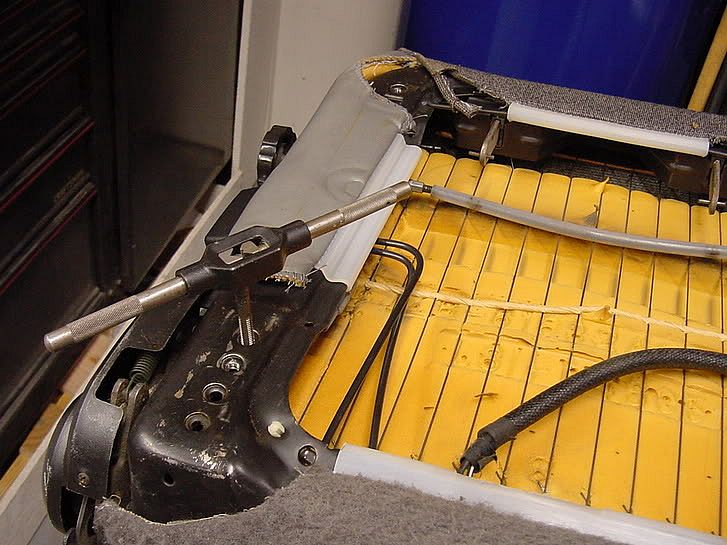

I made my frame out of 3/8" plywood 'cause I needed it to "flex" a bit as it transitioned from 5" wide between the seats to about 8" wide where it meets the dash. I glued 1/8" closed cell foam to it and then black vinyl to the foam. It wraps around and is stapled to the inside.

View attachment 490762

The center is made of 3 pieces of finished oak. The front is cut to accept the air vents from the Vintage Air system I installed back in April. I didn't like the way the micro-switches controlled the compressor, so I added my own switch from a Mazda 323.

The center section has the opening for the Shifter and two cup holders.

The third section has a set of switches from a 82 Thunderbird that are going to control the electric locks (also from the Thunderbird and havn't been installed yet) and electric windows which will be much further in the future.

The top armrest/CD storage lid is at the upholstery shop that did my seats. I'm having it done profesionally since it's probably the most prominant part of it and I want it to match the seats with vinyl on the sides and cloth on top.

I hope to find some kind of plastic bin that will drop into the storage area to give it a nice finished look. (good fiberglass project?)

The door lock relays are mounted at the bottom of the storage area and the wiring harness includes two plugs for easy removal.

I should get more pics up soon.

I made my frame out of 3/8" plywood 'cause I needed it to "flex" a bit as it transitioned from 5" wide between the seats to about 8" wide where it meets the dash. I glued 1/8" closed cell foam to it and then black vinyl to the foam. It wraps around and is stapled to the inside.

View attachment 490762

The center is made of 3 pieces of finished oak. The front is cut to accept the air vents from the Vintage Air system I installed back in April. I didn't like the way the micro-switches controlled the compressor, so I added my own switch from a Mazda 323.

The center section has the opening for the Shifter and two cup holders.

The third section has a set of switches from a 82 Thunderbird that are going to control the electric locks (also from the Thunderbird and havn't been installed yet) and electric windows which will be much further in the future.

The top armrest/CD storage lid is at the upholstery shop that did my seats. I'm having it done profesionally since it's probably the most prominant part of it and I want it to match the seats with vinyl on the sides and cloth on top.

I hope to find some kind of plastic bin that will drop into the storage area to give it a nice finished look. (good fiberglass project?)

The door lock relays are mounted at the bottom of the storage area and the wiring harness includes two plugs for easy removal.

I should get more pics up soon.

. I did have one question though, how did guys go about measuring the hump for fitment.

. I did have one question though, how did guys go about measuring the hump for fitment.  But very nice work

But very nice work