1991notchbackLX

Active Member

Those rubber couplings won't collapse under boost?

Think about this question for a minute...

Those rubber couplings won't collapse under boost?

Think about this question for a minute...

OH they wont blow off either

OH they wont blow off either

Please hurry up and complete this project so that you can move out to my place for a month or two and do mine.

You should concentrate on making the board stop swaying

Thank you. I consider myself..."fooled".Not sure what you're talking about.

Nice, Scott. How much money would you say you have tied up in the tubing with regard to initial purchase? You got it from Mandrebends.com?

Why did you have to wrack your brain on the solution? Looks like an "OH yeah, that'll work" to me.

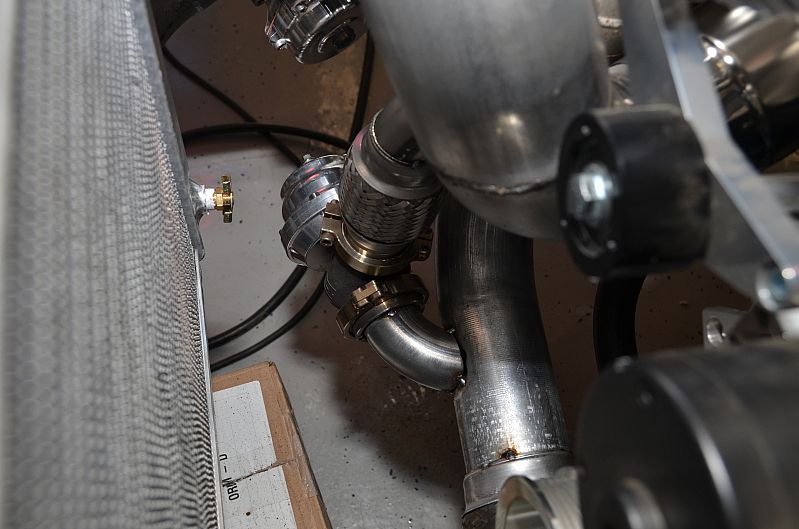

welcome to the "spend an extra afternoon trying to make it work club"I probably have about $350 in the piping and V-band flanges that I bought. All the piping is from MandrelBends, and the V-band flanges are from RacePartsSolutions.com. I could have saved money if I got everything all at once, but I had to make about 2 or 3 extra purchases later on where I had to pay $12 to ship a $20 part. I would venture to say that an entire hotside could be built for around $600 in parts. That would include both headers, crossover, downpipe, y-pipe, and all flanges.

Edit: I would add around $100 in welding gas to that number. There is A LOT of welding to do, and the gas never seems to last as long as you think it would.

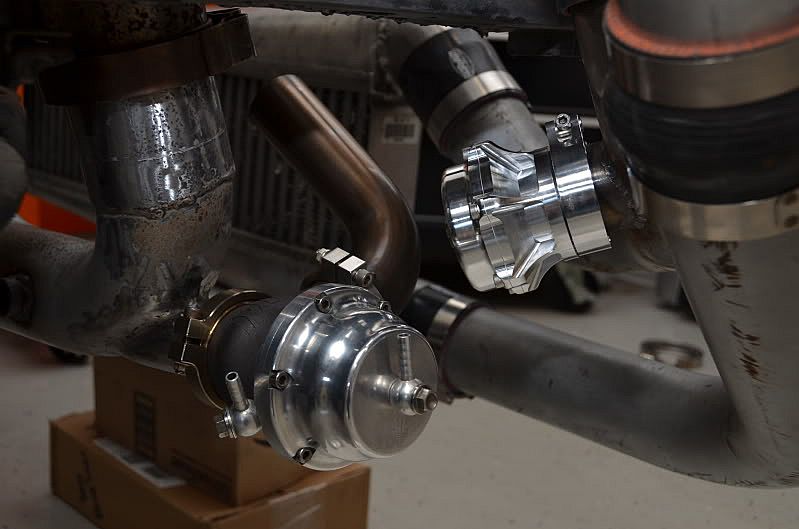

Determining the actual position of the wastegate didn't take too long, but the execution of making it actually happen took some time for whatever reason. I think I was having an off day. It also didn't help that I was trying to use the leftover 1.75" piping from my header rebuild. I really needed another 90 degree bend piece, but instead of spending $30 to get one shipped to my house, I made one that I had laying around work.

I do that all the time. I feel ya on the tubing. I have welded pieces-parts together to make what would've been another U or J bend that I just didn't have.

I do that all the time. I feel ya on the tubing. I have welded pieces-parts together to make what would've been another U or J bend that I just didn't have.Sheesh. Well maybe it'd be easier to overbuy and then sell off the rest after fab is done?

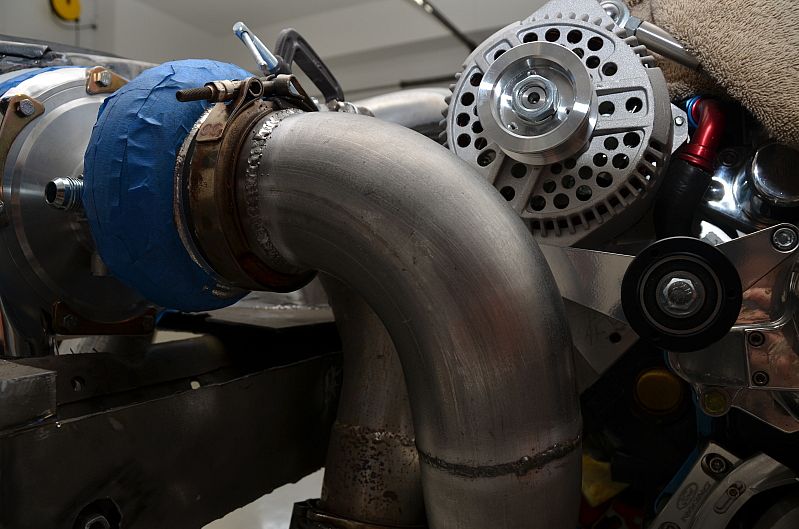

And you're migging all of this right? I could never get the weld bead small enough to look good, and ended up spending another buttload of time grinding and smoothing the welds flush. What are you doing?

I would definitely buy a couple of extra bends and straight pieces. It's better to spend an extra $50 in pipe than to realize you don't have enough pipe to finish everything up. You will be nickled and dimed to death by all those extra shipping costs.

I'm going to bump original parts estimate from $600 to around $900. I threw some parts in a shopping cart at MandrelBends and came to around $650 without shipping. Add shipping, flanges and clamps from RaceParts, and any other odds and ends. It's probably safe to say that a complete hotside to the mufflers will cost around $1000 all welded up. Thennnnn you have to (or at least shoul) send it off to get it all coated. There's another couple hundred there. See how fun this turbo piping stuff is!

So, your pulsing the welder? I do it w/ my exhaust tubing. Your right, it looks good enough for me too. What color are you gonna coat the stuff. I used Jet hot as well, they have a black coating that has the highest heat rating of any of them. Kinda has a finish like they added sand to the mix. I had it on the hotside of my TT Conquest.

Scott, you're scaring me!

Hopefully I can benefit from used parts in some places.

Your welds look great though. what kind of MIG is it? I'm thinking of buying one instead of hauling everything to my buddies shop again.

Scott, you're scaring me!

Hopefully I can benefit from used parts in some places.

Your welds look great though. what kind of MIG is it? I'm thinking of buying one instead of hauling everything to my buddies shop again.