Without you taking a set of calipers and measuring the height and width of each runner opening it’s hard to say.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine Foxbody idle/throttle issues

- Thread starter red5.0fox

- Start date

-

Sponsors (?)

Gotcha. I just read jhricker’s post about lower intake gaskets and I’m beginning to wonder if I just keep putting them in wrong. I’ve changed them twice, but never used any sort of adhesive. I just lay them in there and hope for the best. At this rate, I’m going to continue with the head gaskets, and this time, use the weatherstrip adhesive he was referring to so that I can be sure the gaskets don’t move. And I’ll use the RTV to “bondo” the gasket surface on the intake to make sure everything is smooth.Without you taking a set of calipers and measuring the height and width of each runner opening it’s hard to say.

Strainer or filter. Go here and the replacement of the strainer/filter is at about 7:15

View: https://youtu.be/9x0d7deCMpk?feature=shared

View: https://youtu.be/9x0d7deCMpk?feature=shared

Installation of cylinder heads and valve train:

View: https://youtu.be/7K_aZQfUHQY?feature=shared

Installation of lower intake:

View: https://youtu.be/4UoeazuVbQk?feature=shared

View: https://youtu.be/7K_aZQfUHQY?feature=shared

Installation of lower intake:

View: https://youtu.be/4UoeazuVbQk?feature=shared

TwoRockTwo

Member

I mean, it’s never going to run correctly if you don’t get the base timing correct.

You said it wouldn’t run at 8°-12° BTDC, so where did you end up with for the base timing?

- engine at operating temperature?

- spout removed?

- properly using a timing light on #1 wire?

- verified TDC on cylinder 1 reads 0° on the balancer?

There are things that will cause a stall at idle, and make it hard to set the base timing, things like a vacuum leak, messing with the throttle stop, aftermarket cams, but you have to overcome those.

If it will run with a little bit more throttle, I stick a penny or nickel in between the throttle stop screw and the block just to give it enough rpm so I can finish what I’m doing. It’s just like holding the gas pedal down a little bit.

The only 100% way to find a vacuum leak is with a smoke test, and you can build one for about $10 if you don’t have access.

You have to ensure TDC = 0° and you don’t have any vacuum leaks before you can go any further

You said it wouldn’t run at 8°-12° BTDC, so where did you end up with for the base timing?

- engine at operating temperature?

- spout removed?

- properly using a timing light on #1 wire?

- verified TDC on cylinder 1 reads 0° on the balancer?

There are things that will cause a stall at idle, and make it hard to set the base timing, things like a vacuum leak, messing with the throttle stop, aftermarket cams, but you have to overcome those.

If it will run with a little bit more throttle, I stick a penny or nickel in between the throttle stop screw and the block just to give it enough rpm so I can finish what I’m doing. It’s just like holding the gas pedal down a little bit.

The only 100% way to find a vacuum leak is with a smoke test, and you can build one for about $10 if you don’t have access.

You have to ensure TDC = 0° and you don’t have any vacuum leaks before you can go any further

I set the timing the way as last described, so I’m sure it was done properly. Used a timing light aswell, it just wouldn’t run. The main issue is it does not run properly with the MAF plugged in, it has no throttle, misfires, etc. when the maf is unplugged, it runs smooth, but won’t idle. I did the timing with maf plugged in. There was a vacuum leak sounding like the lower intake, I have a smoke machine and it wasn’t leaking anywhere, no vacuum leaks visible. So currently I’m just replacing head gaskets and everything while I’m here, and I’m going to use jhricker’s way of ensuring the gaskets don’t move so I have a good seal.I mean, it’s never going to run correctly if you don’t get the base timing correct.

You said it wouldn’t run at 8°-12° BTDC, so where did you end up with for the base timing?

- engine at operating temperature?

- spout removed?

- properly using a timing light on #1 wire?

- verified TDC on cylinder 1 reads 0° on the balancer?

There are things that will cause a stall at idle, and make it hard to set the base timing, things like a vacuum leak, messing with the throttle stop, aftermarket cams, but you have to overcome those.

If it will run with a little bit more throttle, I stick a penny or nickel in between the throttle stop screw and the block just to give it enough rpm so I can finish what I’m doing. It’s just like holding the gas pedal down a little bit.

The only 100% way to find a vacuum leak is with a smoke test, and you can build one for about $10 if you don’t have access.

You have to ensure TDC = 0° and you don’t have any vacuum leaks before you can go any further

I’m also going to set engine timing with everything taken apart since apparently that’s the true correct way to do it.I set the timing the way as last described, so I’m sure it was done properly. Used a timing light aswell, it just wouldn’t run. The main issue is it does not run properly with the MAF plugged in, it has no throttle, misfires, etc. when the maf is unplugged, it runs smooth, but won’t idle. I did the timing with maf plugged in. There was a vacuum leak sounding like the lower intake, I have a smoke machine and it wasn’t leaking anywhere, no vacuum leaks visible. So currently I’m just replacing head gaskets and everything while I’m here, and I’m going to use jhricker’s way of ensuring the gaskets don’t move so I have a good seal.

Update: heads are off the engine. I’m going to hot tank them, and powdercoat. Just clean everything up and do it right. However, whoever installed the roller rockers before I got the engine must’ve put a rocker bolt in wrong. It came out tight, and snapped a very small bit off the end in the head. Probably going to have to drill that out. While inspecting the block, I noticed cylinder 3 has some thick clean spots on it, while all the other pistons have a thin coating of grime on them, no clean spots. Unsure what’s going on there..

Also, how do I find out what bolt I need to replace it? Not sure what length and everything it is.Update: heads are off the engine. I’m going to hot tank them, and powdercoat. Just clean everything up and do it right. However, whoever installed the roller rockers before I got the engine must’ve put a rocker bolt in wrong. It came out tight, and snapped a very small bit off the end in the head. Probably going to have to drill that out. While inspecting the block, I noticed cylinder 3 has some thick clean spots on it, while all the other pistons have a thin coating of grime on them, no clean spots. Unsure what’s going on there..

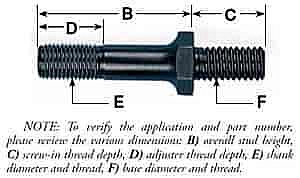

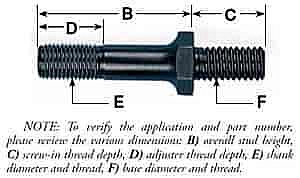

You probably know this but GT40 heads are pedestal style rocker heads stock so they have press in studs. Yours have been converted to bolt in studs which you inherited from the previous owner. With all that said they are most likely 3/8” diameter. I would say that if you have the following dimensions a replacement can be found.

From there call ARP and see if they have one that matches that.

From there call ARP and see if they have one that matches that.

TwoRockTwo

Member

The only proper way to set base timing is with a timing light, while the engine is running.

If you don’t use the timing light, it’s just a guess.

Now, since you used one, where did you end up with the base timing? It’s important to know exactly because it will help diagnose your problem.

You have yet to determine the actual issue, only taken more things apart.

If you don’t use the timing light, it’s just a guess.

Now, since you used one, where did you end up with the base timing? It’s important to know exactly because it will help diagnose your problem.

You have yet to determine the actual issue, only taken more things apart.

I skimmed through the thread so don't shoot me if this has been mentioned...

Are you sure your harmonic balancer isn't shot/garbage? This, aside from what I believe is a bad MAF or MAF wiring that you're working through.

Are you sure your harmonic balancer isn't shot/garbage? This, aside from what I believe is a bad MAF or MAF wiring that you're working through.

Honestly the only reason I went down to the lower intake was because of a vacuum leak. Once I got to that point, I just had the time, and the money so I just wanted to do head gaskets. I’m happy I have, as there were some issues found.The only proper way to set base timing is with a timing light, while the engine is running.

If you don’t use the timing light, it’s just a guess.

Now, since you used one, where did you end up with the base timing? It’s important to know exactly because it will help diagnose your problem.

You have yet to determine the actual issue, only taken more things apart.

If it is, I have a new one! I didn’t feel like restoring the old one and got sick of not being able to see the timing marks, so I scooped up a new one to put on since I get good discounts at my auto stores local to me.I skimmed through the thread so don't shoot me if this has been mentioned...

Are you sure your harmonic balancer isn't shot/garbage? This, aside from what I believe is a bad MAF or MAF wiring that you're working through.

Thanks everyone for the added posts. The new bolt has been secured, and it is thankfully the right one lol. I have gotten almost everything I can powdercoated, and even if the engine doesn’t run right, well, it’ll be super pretty. Before I go further, the only issue I have right now is that my valve stem seals were toast. Now, I have dual valve springs, so the oem style seals don’t work.. however, I’m not sure how to find the correct valve stem seals for my application. Any tips?

As for everything else, here is what I ordered and will be replacing.

- Full Gasket Kit (Doing everything except oil pan and rear main seal)

- Fel-Pro Headbolts

- Harmonic Balancer

-Water pump

- PCV Valve

- Steering shaft rag joint (super easy to reach with everything out)

I’ll take some photos of everything that has been powdercoated aswell because I believe it’s gonna look really good.

As for everything else, here is what I ordered and will be replacing.

- Full Gasket Kit (Doing everything except oil pan and rear main seal)

- Fel-Pro Headbolts

- Harmonic Balancer

-Water pump

- PCV Valve

- Steering shaft rag joint (super easy to reach with everything out)

I’ll take some photos of everything that has been powdercoated aswell because I believe it’s gonna look really good.

TwoRockTwo

Member

You never did answer the very simple question of where exactly you set the base timing using your timing light……

I mentioned in my previous post on the last page that timing was set to 12ish° BTDC and as it would not idle, I simply turned it until it would (I needed the car to move).You never did answer the very simple question of where exactly you set the base timing using your timing light……

I’m setting the engine to TDC on compression stroke while I have the valve covers off.

TwoRockTwo

Member

Yeah but how much did you turn it? Which direction did you turn it?

Advance or retard?

Where did it end up?

Where you started is not as important as where it actually ended up.

Advance or retard?

Where did it end up?

Where you started is not as important as where it actually ended up.

Similar threads

- Replies

- 26

- Views

- 1K

- Replies

- 13

- Views

- 765

- Replies

- 54

- Views

- 4K

- Replies

- 11

- Views

- 721

- Replies

- 25

- Views

- 2K