Hey Guys,

I have a '67 that I'm restoring. I am basically running a late model (87-93) engine and fuel injection/computer system, so this is probably the best place for help. I have a DSS 306 with AFR185s, forged rods & pistons, GT40 lower that will hook up to my Kenne Bell 2.2 w/ flowzilla inlet...compression at 8.4...75mm throttle body, 80mm mass air, 42lbs injectors, aeromotive fuel system and more...

I'm probably going to drop in and hook up the engine myself, but I have much to learn on the way. Can you tell me what the following are??

1.?

2.?

3.?

4.?

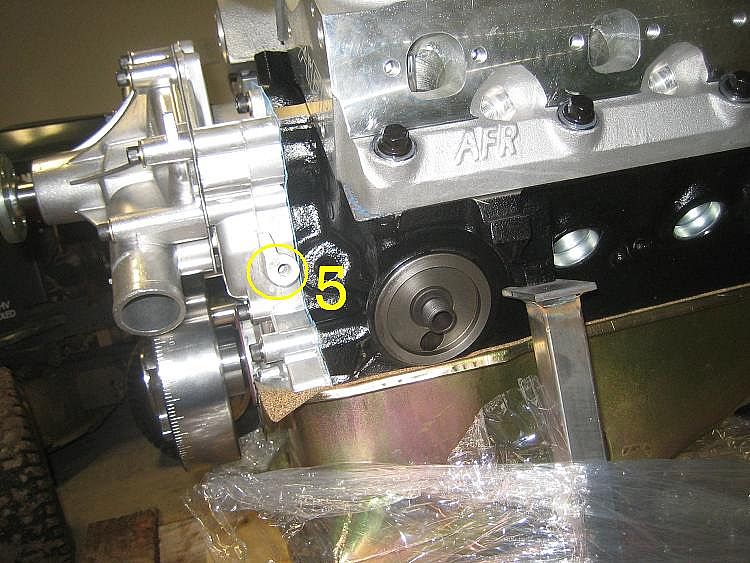

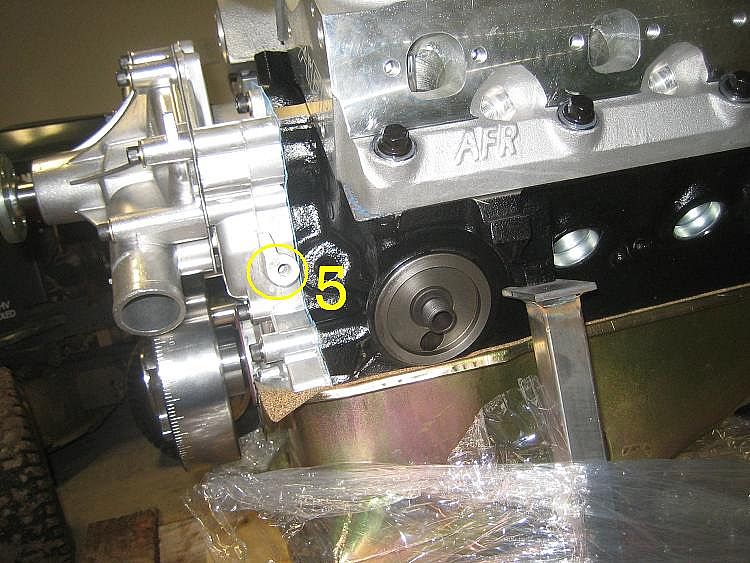

5.?

Also, where do I make the connections for vacuum?? Ill need to hook up a brake booster, FPR, and more. Will it be on the upper intake?

I have a '67 that I'm restoring. I am basically running a late model (87-93) engine and fuel injection/computer system, so this is probably the best place for help. I have a DSS 306 with AFR185s, forged rods & pistons, GT40 lower that will hook up to my Kenne Bell 2.2 w/ flowzilla inlet...compression at 8.4...75mm throttle body, 80mm mass air, 42lbs injectors, aeromotive fuel system and more...

I'm probably going to drop in and hook up the engine myself, but I have much to learn on the way. Can you tell me what the following are??

1.?

2.?

3.?

4.?

5.?

Also, where do I make the connections for vacuum?? Ill need to hook up a brake booster, FPR, and more. Will it be on the upper intake?