General, your thoughts are not looneytoons at all. In simple terms, if you want more horsepower, make more torque, or to put it another way, if you want more torque, make more horsepower. Let's say that you put your engine on a dyno to find out how much horsepower it makes. The interesting thing is that a dyno does not measure horsepower, it only measures torque. From that torque measurement, a computer using an algorithm tells you how much horsepower you made.

Let's go back to the basics for a minute and define what we are talking about.

Energy is the capacity for doing work. In this instance, engines perform the work formerly done by horses.

Work is the result of a force acting over some distance. The U.S. measurement unit for work (and also energy) is foot-pounds.

Torque is a rotating force produced by an engine’s crankshaft. The more torque an engine produces, the greater its ability to perform work. The measurement is the same as work, but slightly different. Since torque is a vector (acting in a certain direction), it’s quantified by the units pound-feet and newton-meters.

Of course, there’s always an exception. In this case the distinction is

static torque, the kind you apply with a wrench to tighten head bolts. To avoid confusion, the units for static torque are traditionally foot-pounds.

Power is how rapidly work is accomplished. Eighteenth-century Scottish inventor James Watt gave us this handy equivalency: one horsepower is the power required to lift 33,000 pounds exactly one foot in one minute.

Torque is the capacity to do work, while power is how quickly some strenuous task can be accomplished. In other words, power is the rate of completing work (or applying torque) in a given amount of time. Mathematically, horsepower equals torque multiplied by rpm divided by 5252 (a constant). So, to make more power an engine needs to generate more torque, operate at higher rpm, or both.

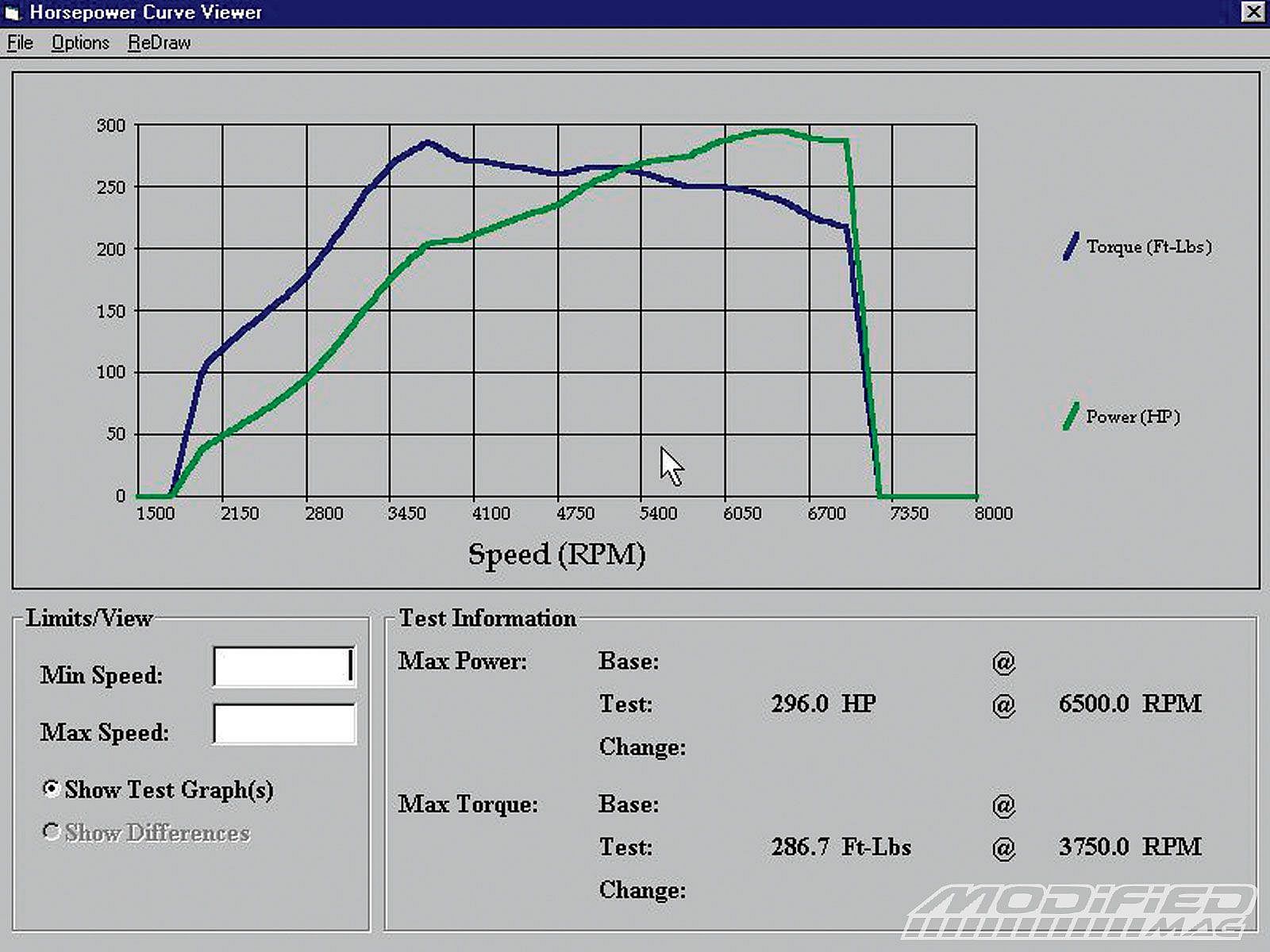

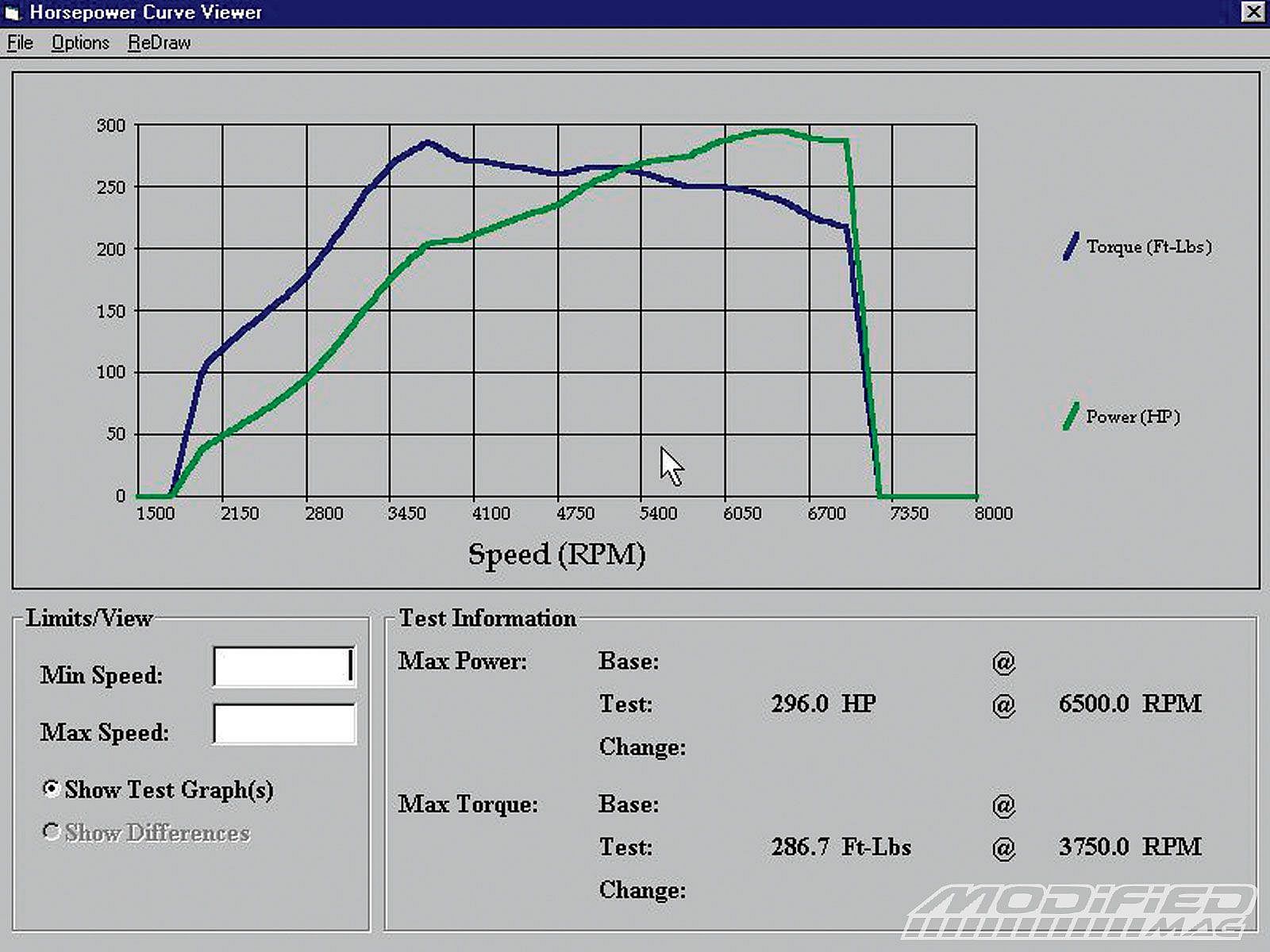

The next time you look at a dyno sheet (magazines that do dyno tests print the sheet out) so we can see how much torque and how much horsepower there is at given rpm's. Look at this typical dyno sheet. The blue line is the torque, the green line is the horsepower, and the RPM's are shown at the bottom of the chart. Notice that the lines cross at exactly 5,252 RPM. You will see this on every dyno sheet that you ever read. The blue line (the torque) is the only thing that the dyno measures, the green line (the HP) is extrapolated from the torque readings and the RPM. I have never seen a dyno sheet in which the torque is not higher than the HP number under 5,252 RPM, or lower than the HP number above 5,252 RPM. So, relative to the diameter of the primary tubes on headers (1 5/8" or 1 3/4" or 1 7/8", etc.) or the length of the primary tubes, not much is going to affect the torque on your engine, only the potential horsepower power of your engine. More power gives you more torque, because more torque gives you more power. We better stop now, because it's not quite 7:30 AM where I am and I'm already thinking about a double scotch (no ice please)...